DC-DC power supply device

A DC-DC, DC power supply technology, applied in high-efficiency power electronic conversion, conversion equipment with intermediate conversion to AC, climate sustainability, etc. Reduce the volume and weight of the device to achieve the effect of increasing the switching frequency, ensuring the safe operation of the system, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

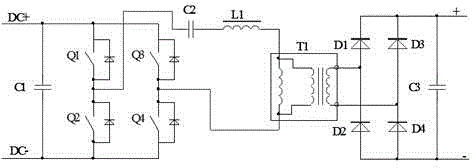

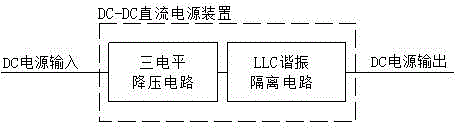

[0022] Such as image 3 Shown: a DC-DC direct current power supply device, including such as figure 1 The three-level step-down circuit shown and as figure 2 In the LLC resonant isolation circuit shown, the input terminal of the three-level step-down circuit is connected to the input DC power supply Ui, and the output terminal U0 of the three-level step-down circuit is connected to the DC input terminal of the DC power supply of the LLC resonant isolation circuit; the LLC resonant isolation circuit The output terminal of the DC power supply is connected to the DC power supply load, that is: the input DC power supply Ui is stepped down by a three-level step-down circuit to a lower DC voltage output, and then converted to a stable DC voltage output by an LLC resonant isolation circuit.

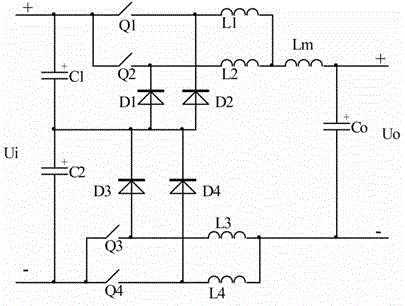

[0023] Such as figure 1 As shown: the three-level step-down circuit in this embodiment is composed of filter capacitors connected in sequence, a rectifier circuit composed of four diodes D1-D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com