Angle adjusting assembly of pelletizer

A technology of angle adjustment and ball making machine, which is applied in the direction of using feedback control, etc., can solve the problems of inability to remotely adjust the inclination of the ball disc, increase the labor intensity of manual balling, and difficult to control the size of the balls. Improve dimensional accuracy, reduce force intensity, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

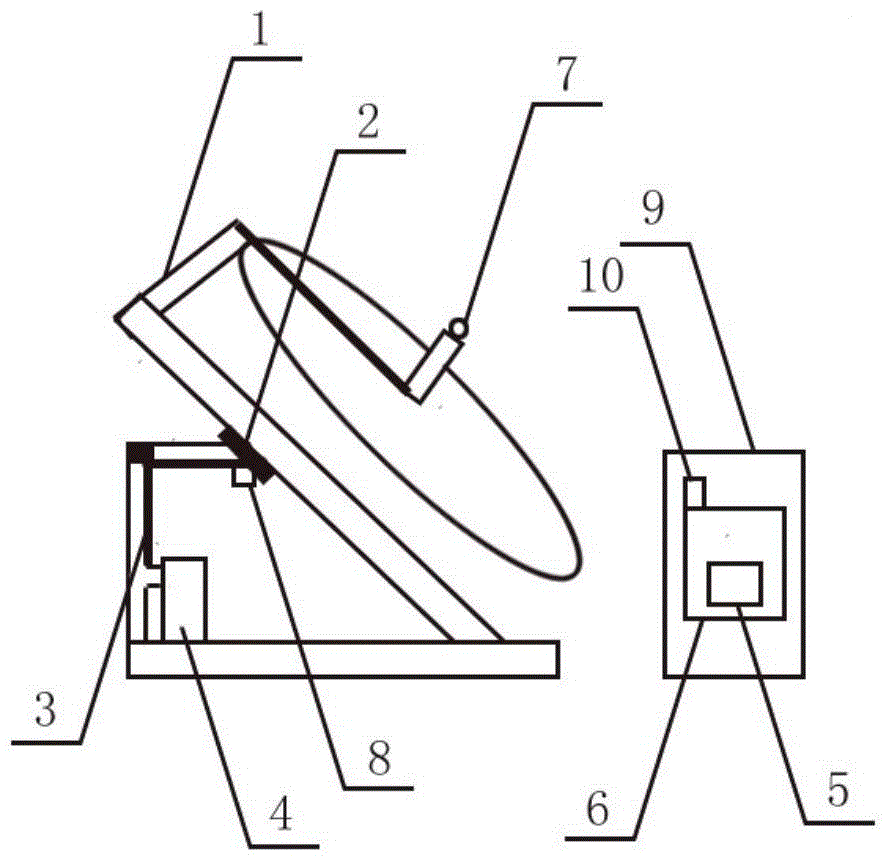

[0012] Embodiment: as shown in the accompanying drawing. The angle adjustment assembly of the ball making machine includes a ball making machine body (1), and the air pressure telescopic adjustment device (2) is installed at the bottom of the ball plate support frame of the body (1), and the air pressure generating device (4) is connected to the air pressure generating device (4) through a hollow pipeline device (3) , the control module (5) is connected with the display device (6), and the monitoring device (7) is arranged on the top of the scraper frame of the ball disc to observe the running dynamics of the disc, and adjust the inclination angle of the pelletizing machine according to the size of the forming balls of the disc.

[0013] The angle adjustment component of the pelletizing machine, the pneumatic telescopic adjustment device (2) has a variety of directions, and the angle detection module (8) is installed at the bottom, and the inclination and height data are transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com