A material supervision system and method for a smart factory

A technology for monitoring systems and materials, applied in a variety of biometric applications, logistics, biometric identification, etc., can solve the problems of time-consuming training of personnel, less application of production product data, difficulty in ensuring accuracy, etc., to achieve three-dimensional The effect of environmental detection, automatic tracking, and easy countermeasures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

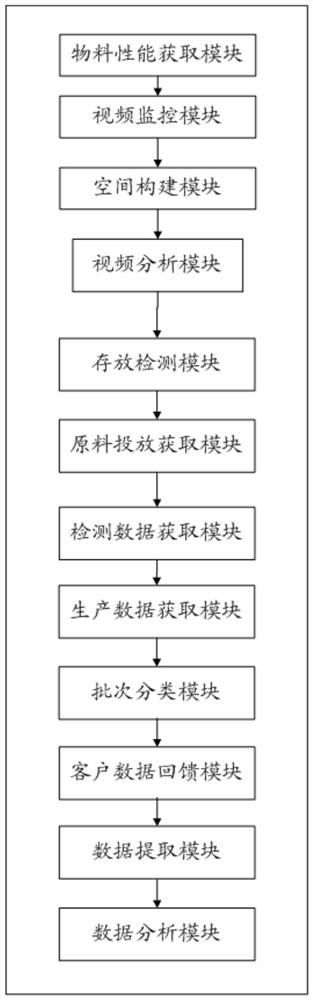

[0046] refer to figure 1 , in this embodiment, a material supervision system of a smart factory is proposed, which is used to monitor factory materials. The material supervision system of the smart factory includes:

[0047] The material performance acquisition module is used to acquire the material information of the material in the material package. The material performance acquisition module can manually input the material information when the material enters the warehouse, or scan the QR code on the material package with a code scanner to obtain Material information. Scanning with a scanner gun can avoid manual input, improve the efficiency of materials entering the warehouse, and reduce the workload.

[0048] The video surveillance module can be installed inside the warehouse, and is used for video surveillance of the material packages inside the warehouse to obtain surveillance information. A plurality of the video monitoring modules can be set, and the arrays are dist...

Embodiment 2

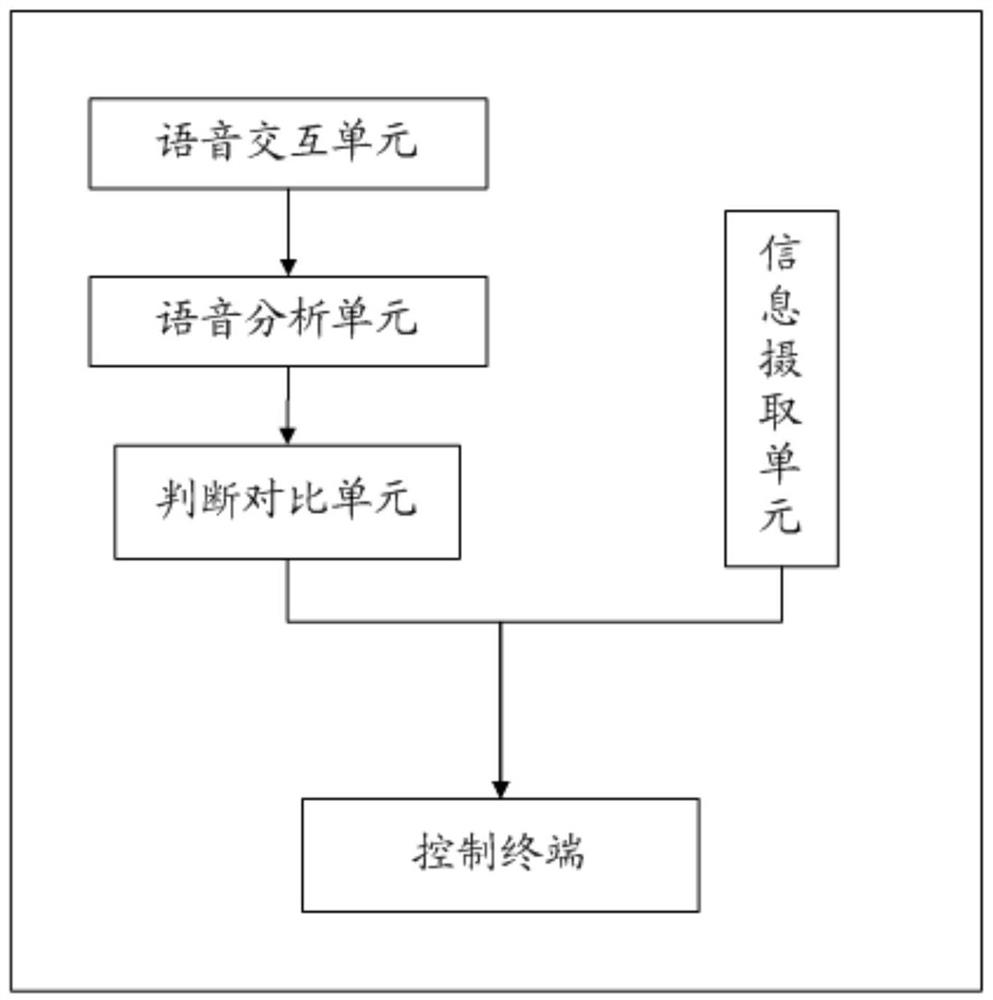

[0061] refer to figure 2 , the material supervision system of the smart factory also includes: a voice interaction unit, which is used for inputting voice information and performing voice interaction, so as to conduct voice inquiry, voice instruction, etc., so as to increase the instruction ability and work efficiency.

[0062] The voice analysis unit is used to receive voice information, analyze the voice information to obtain voice features, and determine whether the voice features belong to a preset voice feature-person information table. ; If yes, it is determined to be a person in the factory. The personnel information is obtained by searching the voice feature-person information table, and a preset personnel-access level information table is searched according to the personnel information, thereby obtaining the access level. The speech analysis unit can distinguish by analyzing the timbre, frequency, etc. of the speech information, which will not be described in detail...

Embodiment 3

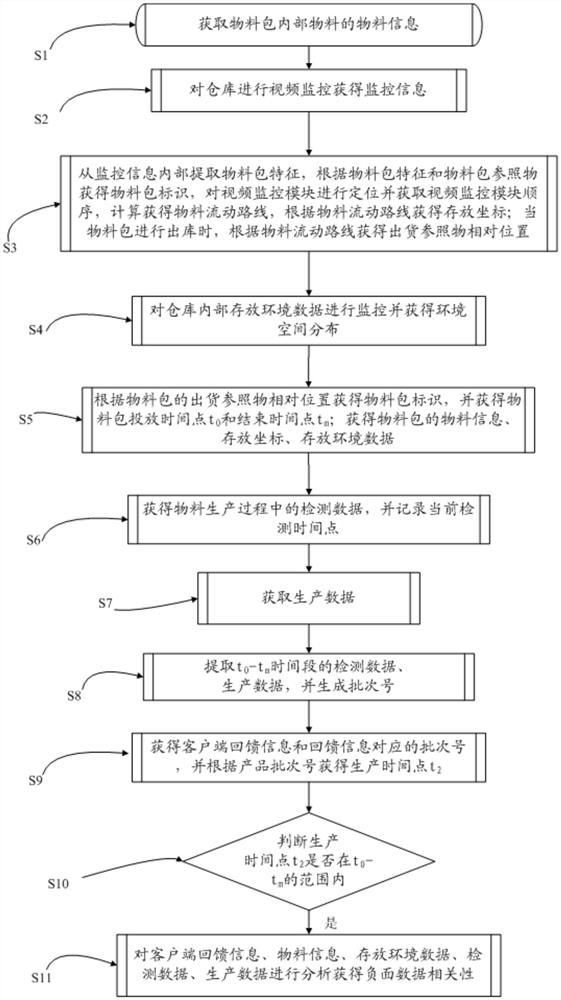

[0068] refer to image 3 , in this embodiment, a material supervision method for a smart factory is proposed, which includes the following steps:

[0069] S1. Obtain the material information of the material in the material package.

[0070] S2. Perform video surveillance on the warehouse to obtain surveillance information.

[0071]S3. Extract the material package features from the monitoring information, bind the material package features with the material information, analyze the monitoring information, obtain the material package identification according to the material package characteristics and the material package shipping reference, and obtain the material package identification The video surveillance module is located and the sequence of the video surveillance module is obtained, the material flow route is obtained by calculation, and according to the material flow route, it is judged whether the material package is in the warehouse or out of the warehouse; when the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com