Installation and debugging method of Beidou generation-II navigation system electric iron tower deformation monitoring device based on machine learning

A machine learning and navigation system technology, applied in navigation, surveying devices, surveying and navigation, etc., can solve the problems of low installation accuracy, low efficiency, poor adaptability, etc., to reduce difficulty, improve work efficiency and quality, and realize automatic Improvements and cumulative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

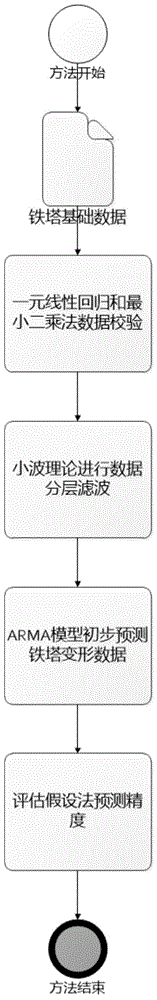

[0026] The implementation process of the installation and commissioning method of the Beidou II power tower deformation monitoring equipment based on machine learning is as follows: figure 1 shown. The specific implementation process is as follows:

[0027] 1. Univariate linear regression and least squares data verification

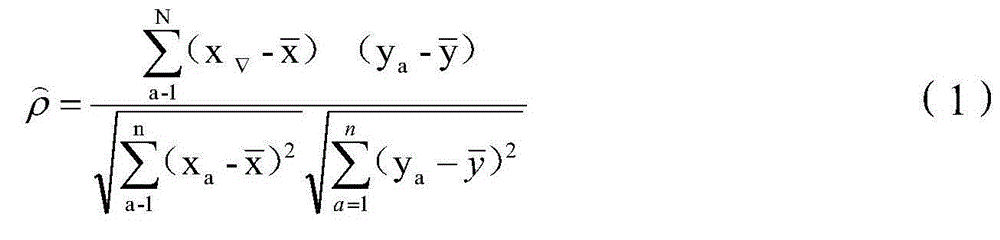

[0028] Acceleration and inclination are calculated according to the data collected by the deformation of the iron tower. Correlation coefficient of wind speed

[0029]

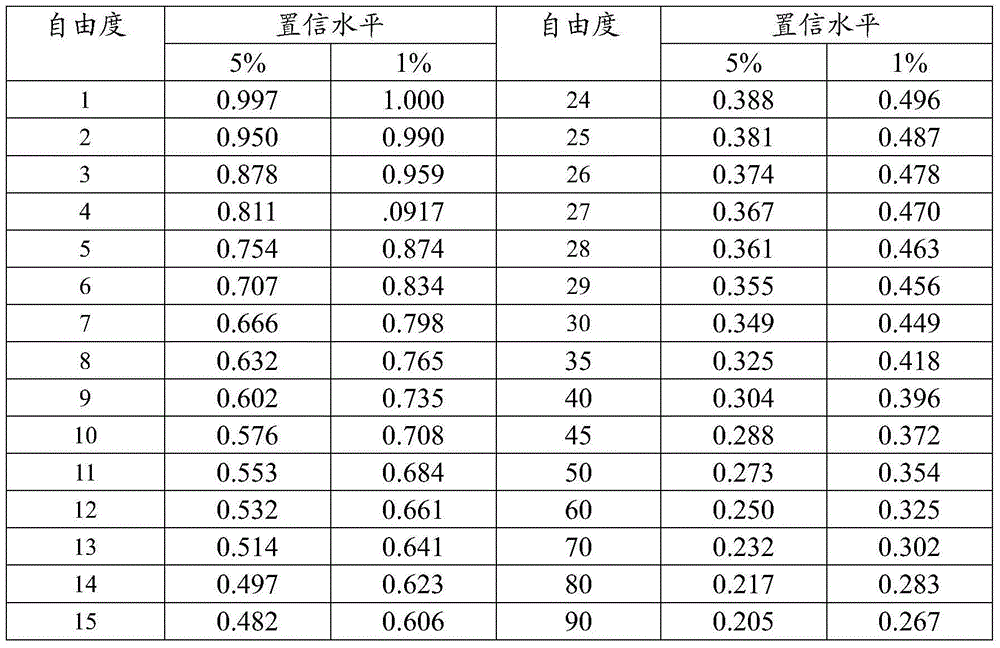

[0030] Referring to Table 1, when calculating the is greater than the corresponding value in the table, it can be considered that the correlation meets the conditions for configuring the regression line, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com