High precision sensor protection device

A technology of protection devices and sensors, applied in the direction of measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

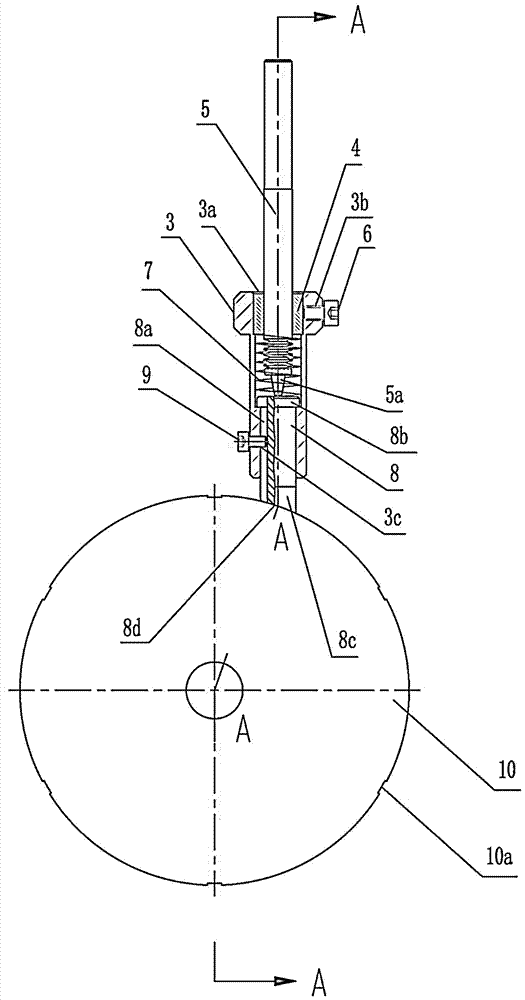

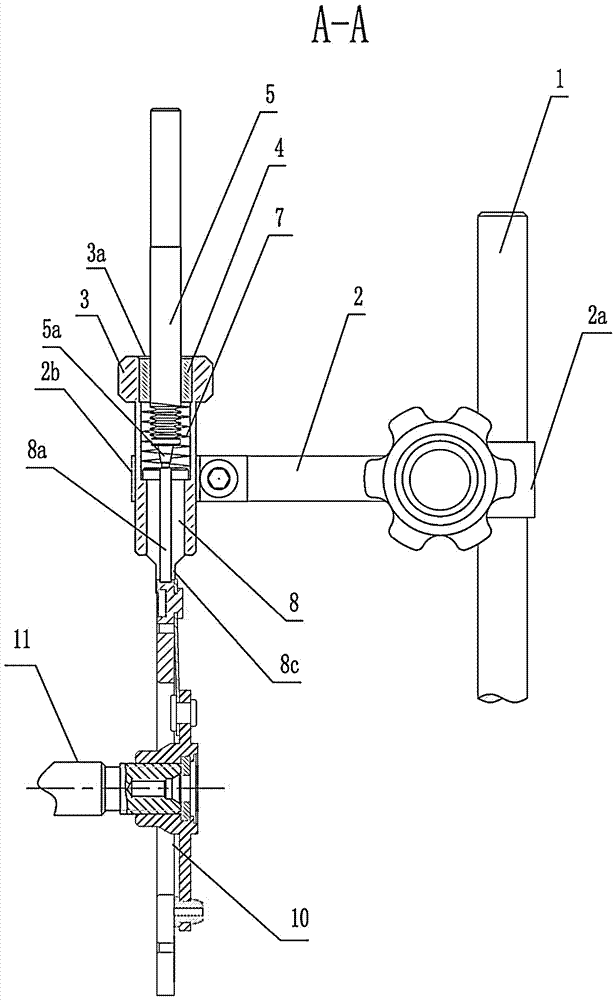

[0015] High-precision sensor protection devices, such as figure 1 and figure 2 As shown, it includes a universal strut 1, the universal strut 1 is adjustably connected to the cantilever 2 through an adjustable hoop 2a, one end of the cantilever 2 is fixedly connected with a cylindrical tubular shell 3 through a fixed hoop 2b, and the center of the tubular shell 3 The hole is set as a three-step circular step hole 3a, a set screw hole 3b is set on the side wall of the upper step hole, and a non-rotation hole 3c is set on the side wall of the bottom step hole, and the anti-rotation hole 3c is a threaded hole. A hollow cylindrical ferrule 4 is assembled in the upper step hole, and the inner hole of the ferrule 4 is socketed with a sensor 5 . A set screw 6 is assembled in the set screw hole 3b, and the set screw 6 compresses the ferrule 4, and the ferrule 4 clamps the sensor 5 tightly.

[0016] A cylindrical moving slider 8 is installed in the lower step hole, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com