Method for testing interfacial fracture toughness of second-generation high-temperature superconducting strip

A technology of high-temperature superconducting strips and fracture toughness, which is applied in the preparation of test samples, testing the strength of materials by applying a stable bending force, and testing the strength of materials by applying a stable tension/pressure, which can solve the problems affecting the use of strips , Difficult to test and other problems, to achieve the effect of ensuring the accuracy of the experiment, easy to implement, and simple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The solutions of the present invention will be further described below in conjunction with specific examples.

[0026] A method for testing the interface fracture toughness of a second-generation high-temperature superconducting strip, comprising the following steps:

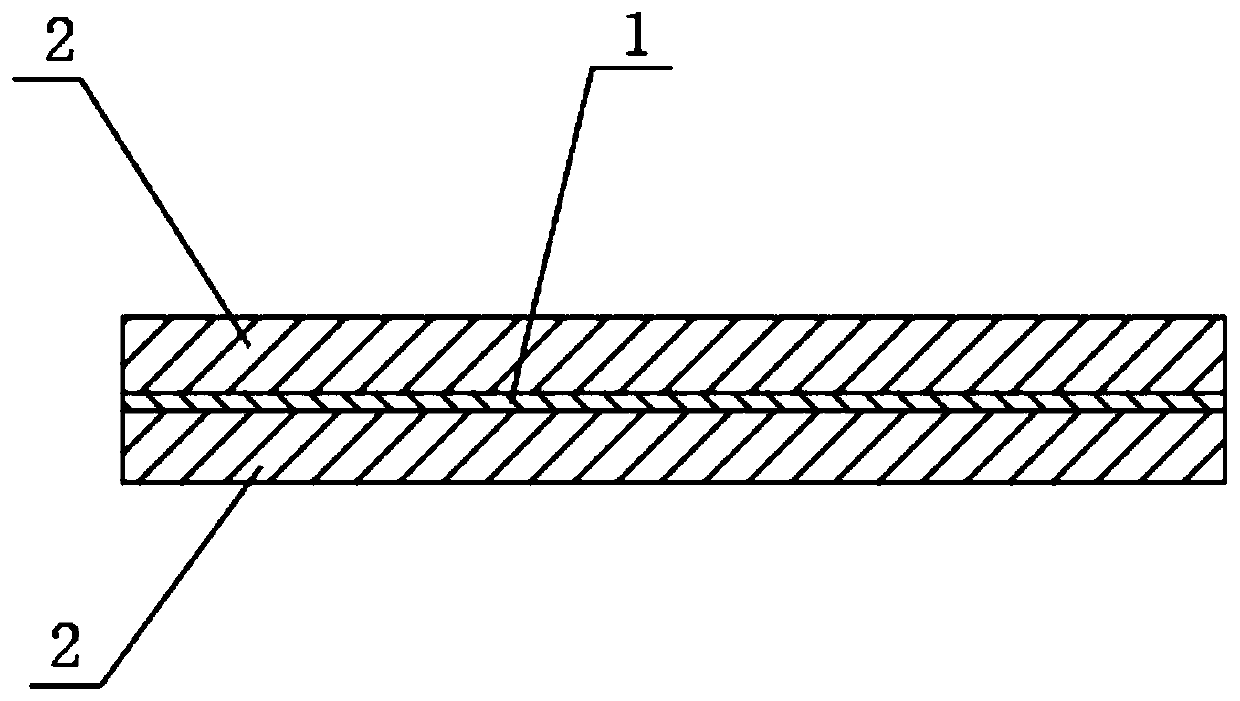

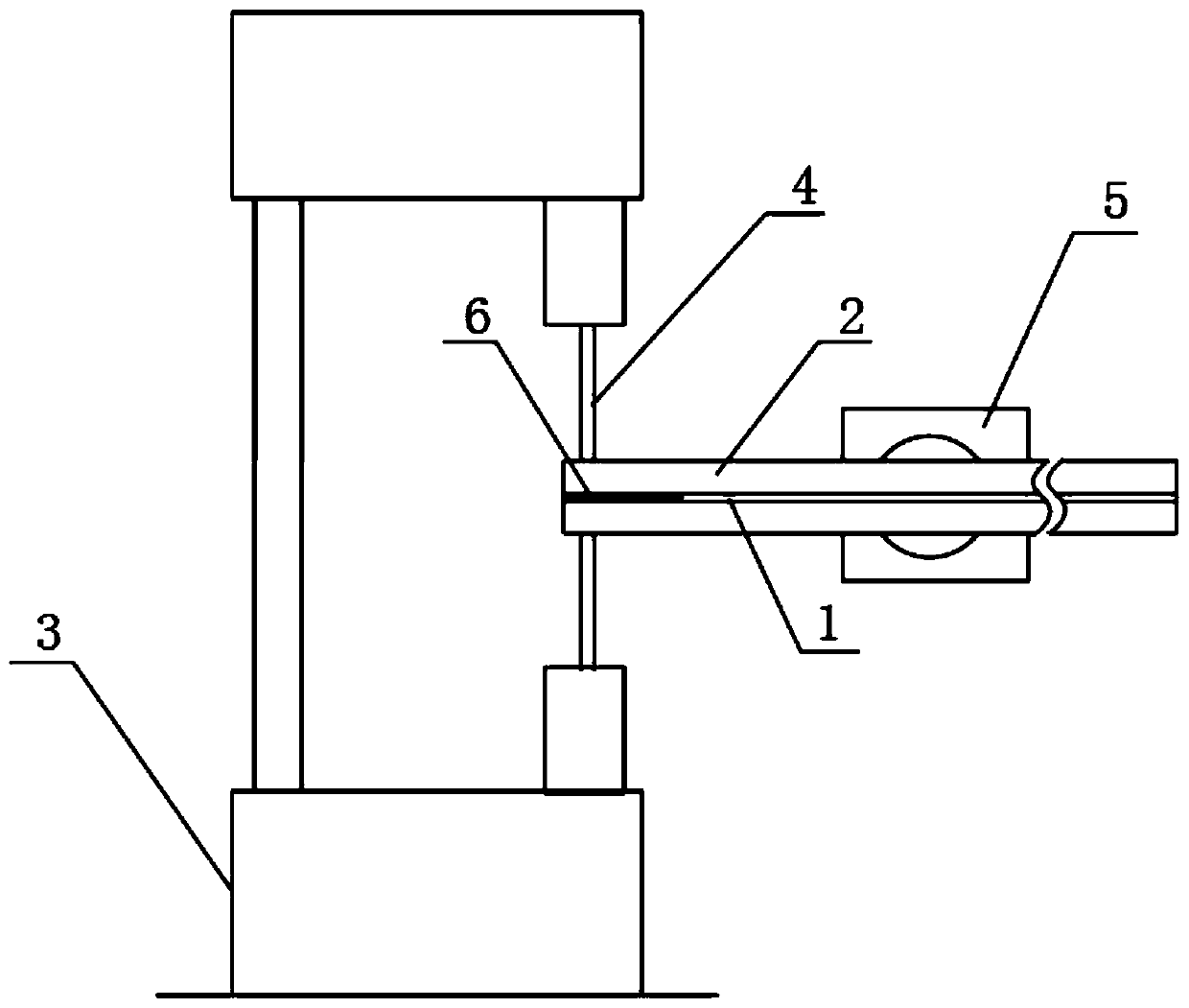

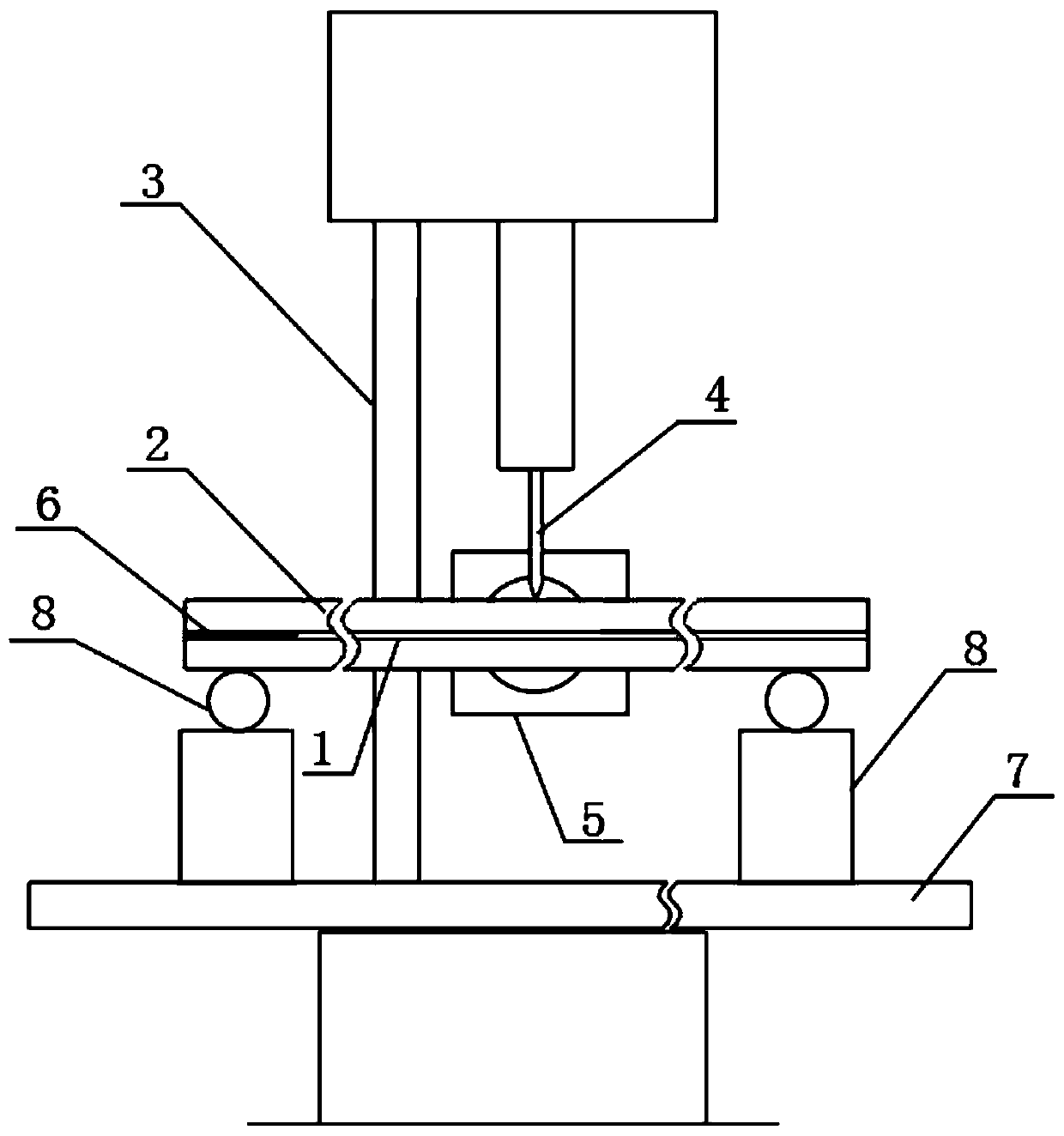

[0027] (1) if figure 1 As shown, on both sides of the superconducting strip 1, the solidified thickness is much larger than its reinforcing layer 2, forming a composite beam structure and as a sample to be tested. 30 times, and the reinforcing layer 2 on both sides of the superconducting strip 1 has the same thickness, and the length of the reinforcing layer 2 is the same as that of the superconducting strip 1; the material of the reinforcing layer 2 can be selected from epoxy resin, oxygen-free copper or stainless steel, and High-strength glue can be used for bonding and curing. When oxygen-free copper or stainless steel is selected as the reinforcement layer, special solder for superconducting material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com