Device for using high pressure gas to drive bullet to remove rotary kiln outlet slag

A high-pressure gas and rotary kiln technology, applied in the direction of descaling devices, drum furnaces, furnaces, etc., can solve the problems of high material requirements for devices, achieve effective slag removal, avoid dangerous factors and heavy manual labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

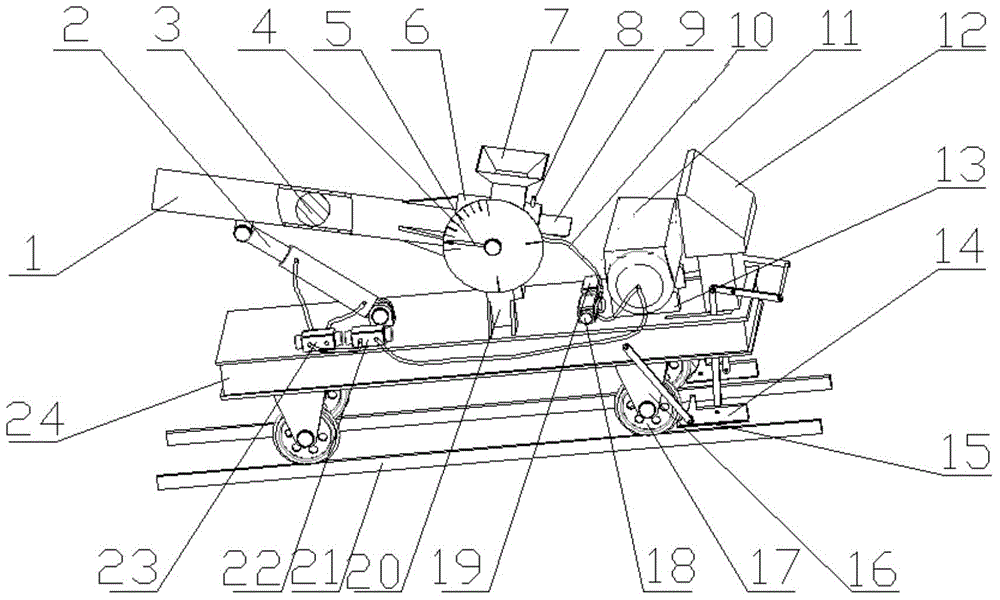

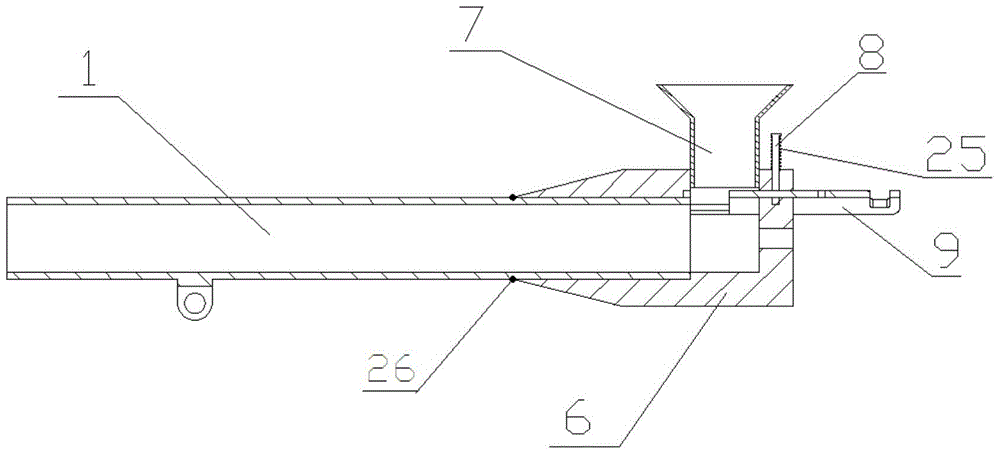

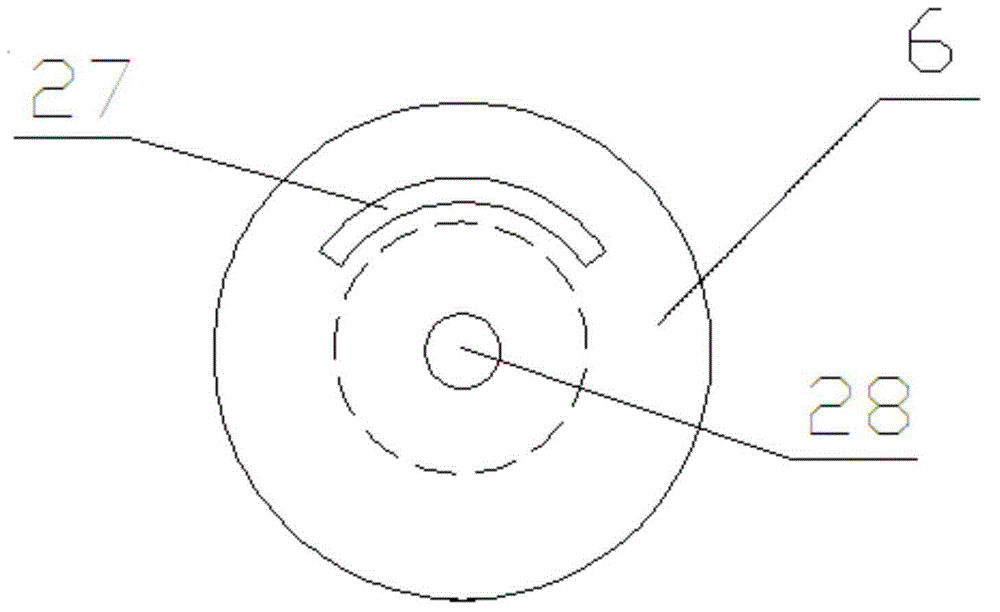

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a high-pressure gas pushes the projectile to remove slagging at the outlet of the rotary kiln. Magazine lock pin 8, magazine cover 9, high-pressure air duct 10, air compressor and pressure tank 11, control panel 12, air cylinder bracket 13, wheel locking system 14, brake pads 15, wheel bracket 16, wheels 17, overflow valve 18, electromagnetic one-way valve 19, loading magazine support 20, track 21, reversing valve 23, base plate 24 and spring 25 constitute. The tube body 1 is connected with the pneumatic cylinder 2, and the projectile 3 enters the loading chamber 6 through the loading funnel 7. Under the action of high-pressure gas, it is pushed into the tube body 1 and then ejected. The bullet funnel 7 is welded together by the welding port 26; the dial 4 and the pointer 5 are installed on the loading bin bracket 20 on the side of the loading bin 6, and the loading bin cover 9 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com