Drying machine

A dryer and outer cylinder technology, applied in the field of dryers, can solve the problems that granular fertilizers are easily broken, cannot be effectively used, and are easy to agglomerate, and achieve the effect of reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

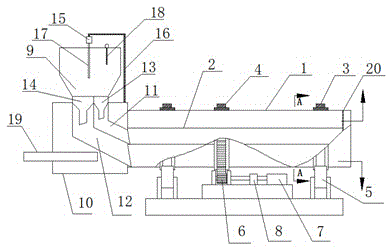

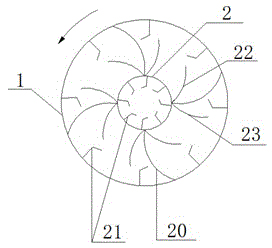

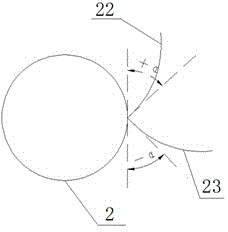

[0013] Example. a dryer such as Figure 1-3 As shown, it includes an outer cylinder body 1, an inner cylinder body 2 coaxial with the outer cylinder body 1 is provided, a feed housing 10 is provided at one end of the outer cylinder body 1, and an air inlet pipe 19 is provided inside the feed housing 10 , the two supporting rings 3 and the ring gear 4 on the wall of the outer cylinder 1, the ring gear 4 is arranged between the two supporting rings 3, and the matching supporting wheel 5 is correspondingly provided under the supporting ring 3, and the ring gear 4 A gear 6 is arranged below, and the gear 6 is meshed with the ring gear 4, and the motor 7 transmits the gear 6 through a transmission 8; a hopper 9 is arranged above the feeding housing 10, and a hygrometer 18 is arranged in the hopper 9; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com