Method for assembling super-large-diameter pressure steel pipes in whole joints

A technology of penstocks and ultra-large diameters, which is applied in the field of full-section assembly of super-large-diameter penstocks, which can solve the problems of long construction period, heavy workload, and high construction costs, and achieve the effects of saving construction investment, simple operation, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

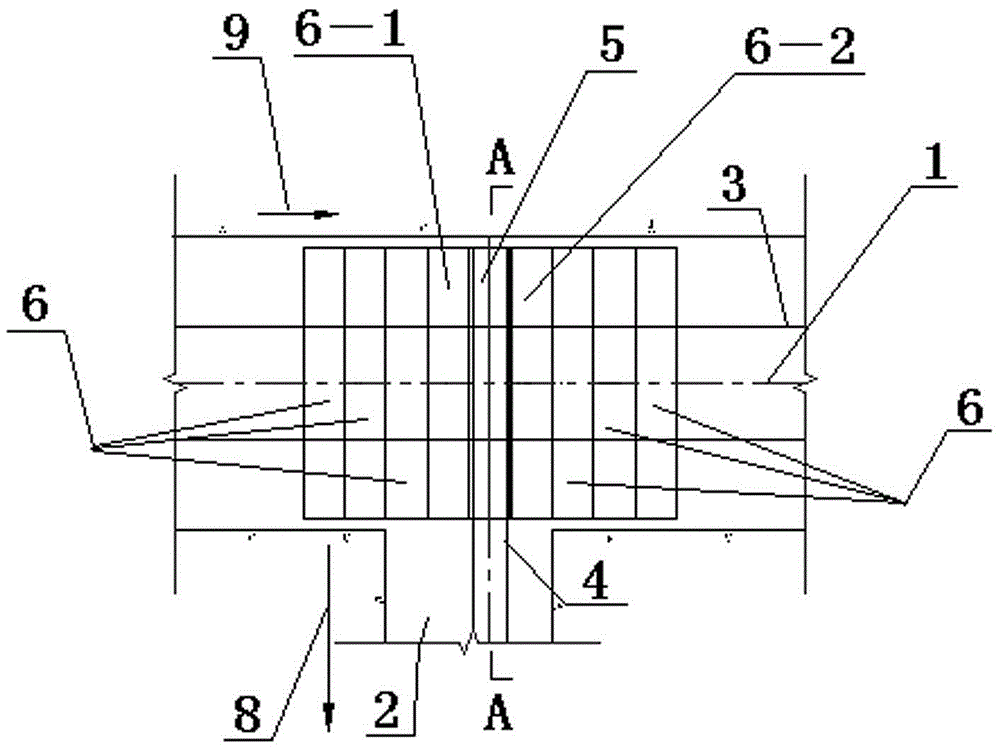

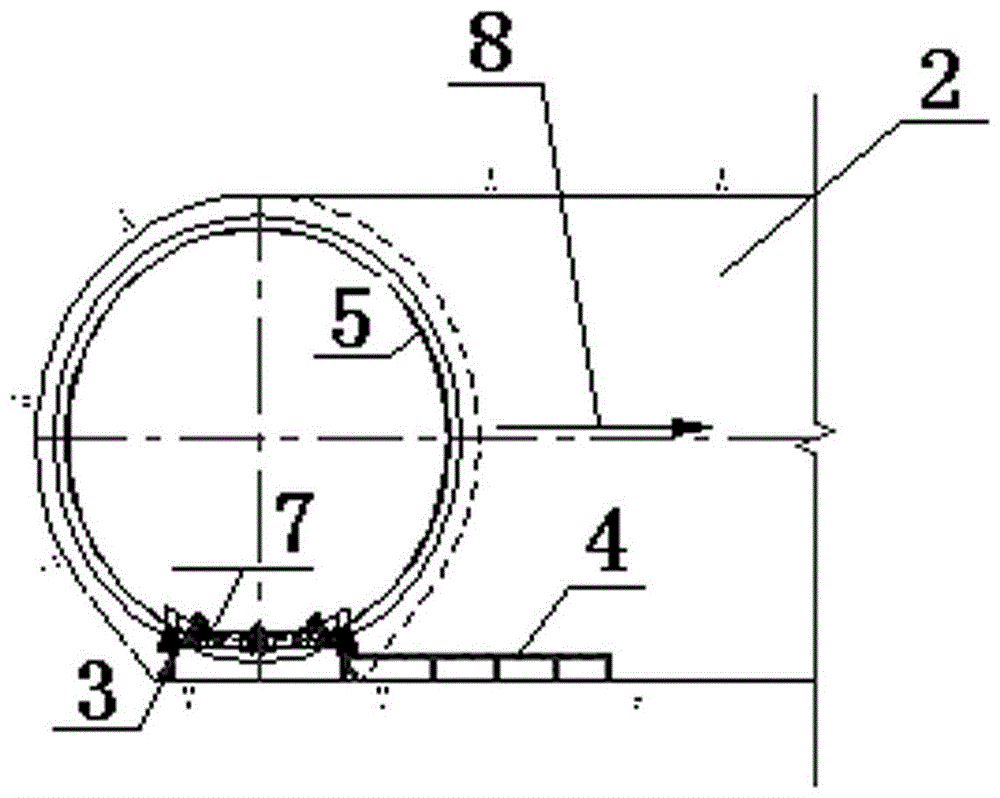

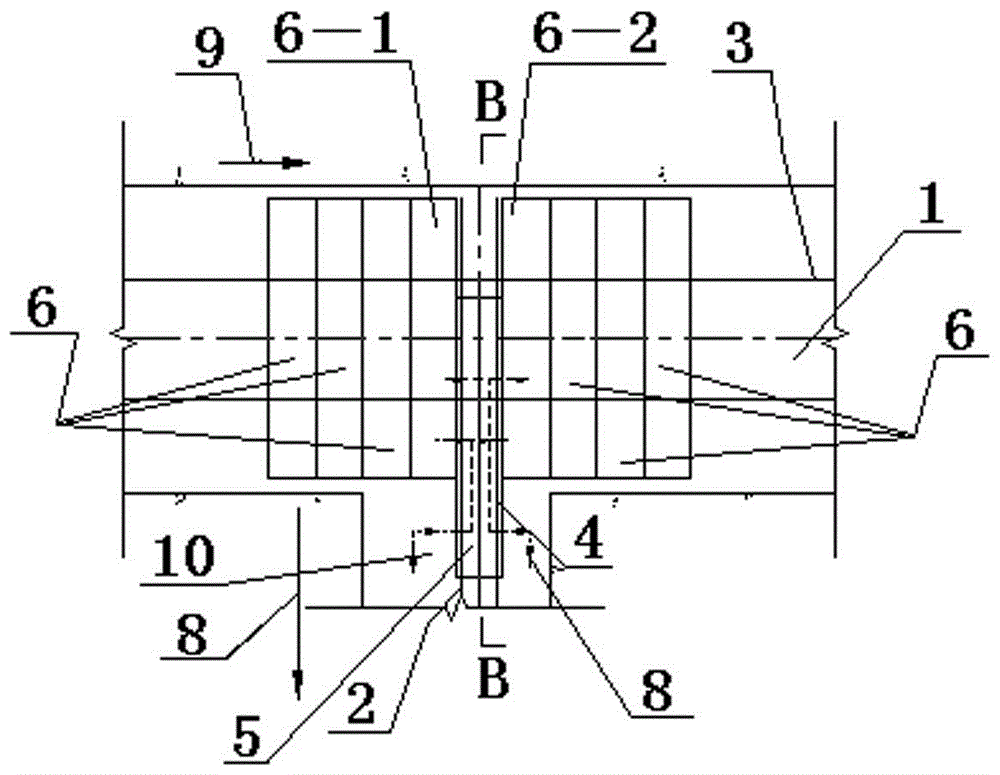

[0023] Figure 1 to Figure 7 The serial numbers 1, 2, 3, 4, 5, 6, 6-1, 6-2, 7, 8, 9, 10, 10-1 respectively represent the water diversion tunnel, construction branch tunnel, installation track, cross track, pressure Steel pipe joints, penstocks, front penstocks, rear penstocks, universal wheel trolleys, displacement directions of penstock joints, water flow directions, temporary passage directions, and reserved construction passages.

[0024] In this embodiment, the super-large-diameter penstock steel pipe assembly method adopts the whole joint penstock joint, universal wheeled trolley, and cross track:

[0025] (1) The joint of the entire pressure pipe: the joint of the pressure pipe should be cut from the whole sheet, and it can be rolled after the groove is processed. Bend pipes and transition section pipe joints can also be selected as whole joints according to the actual working conditions on site, and straight pipes are suitable. It is consistent with other pressure ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com