A pdc drill bit used in a hydraulic rotary punching device

A drill bit and hydraulic technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and production, etc., can solve the problems that have not been simulated, less research, instability and deflection, etc., and achieve the effect of increasing the drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

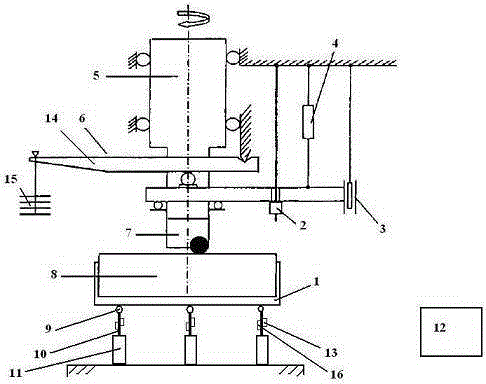

[0025] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0026]First of all, the directions "front", "rear", "left", "right", "upper (top)", "lower (bottom)" and "side" in the present invention are only based on the appended figure 1 The state in which the experimental device is placed is convenient for understanding the definitions of the technical solutions of the present invention. Those skilled in the art can understand that these definitions about directions should not be interpreted as limitations on the claims and technical solutions of the present invention; In the invention, the drill bit is specially used for the hydraulic rotary punching device, wherein "special purpose" only means that the drill bit used in the device can be connected and installed according to the assembly method understood in the mechanical field, and those skilled in the art can understand the meaning of "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com