System for preparing kudzu vine rope

A kudzu vine rope and extractant technology, which is applied in the chemical post-treatment of fibers, textiles and papermaking, mechanical treatment, etc., and can solve the problems of mildew, moisture, and low rope strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

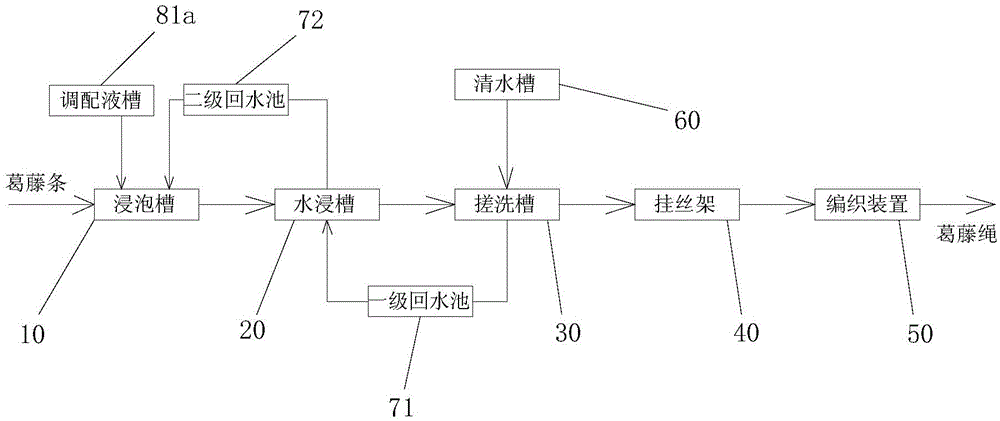

[0016] kudzu rope production systems such as figure 1 Shown: comprise the immersion tank 10 that is used to soak kudzu vine bar that is arranged in order, the water immersion tank 20 that is used to soak the kudzu vine bark after soaking and peeling, the rubbing tank 30 that rubs the peeled kudzu vine bark for scrubbing, The kudzu vine bark fiber after rubbing and washing is carried out the wire hanger 40 of splitting and drying, and the weaving device 50 for weaving the kudzu vine bark fiber silk into rope; the water inlet of scrubbing tank 30 and the clear water tank 60 outlet of storing clear water Connected, the water outlet of the scrub tank 30 is connected with the water inlet of the first-level backwater pool 71, the water outlet of the first-level backwater pool 71 is connected with the water inlet of the water immersion tank 20, and the water outlet of the water immersion tank 20 is connected with the second-level water outlet. The water inlet of the backwater pool 72...

Embodiment 2

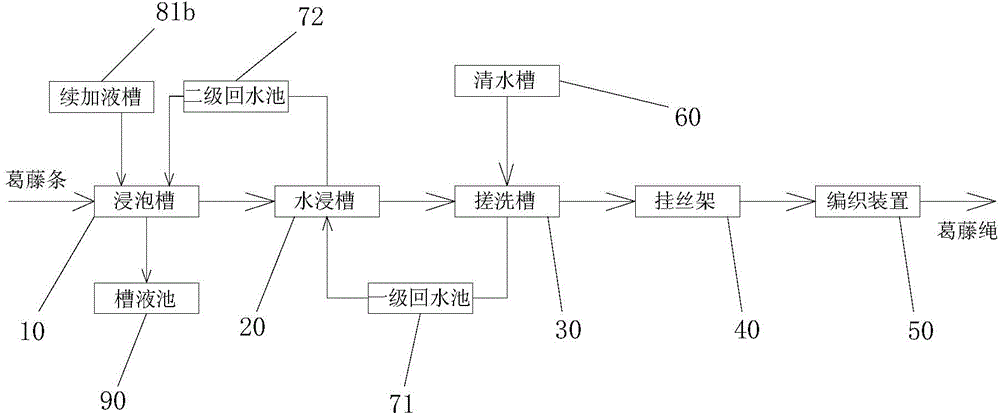

[0024] kudzu rope production systems such as figure 2 , 7Shown: include the immersion tank 10 that is used to soak kudzu vine bark that is arranged in order, the water immersion tank 20 that is used to soak the kudzu vine bark after soaking and peeling, the rubbing tank 30 that scrubs the peeled kudzu vine bark by rubbing, The kudzu vine bark fiber after rubbing and washing is carried out the wire hanger 40 of splitting and drying, and the weaving device 50 for weaving the kudzu vine bark fiber silk into rope; the water inlet of scrubbing tank 30 and the clear water tank 60 outlet of storing clear water Connected, the water outlet of the scrub tank 30 is connected with the water inlet of the first-level backwater pool 71, the water outlet of the first-level backwater pool 71 is connected with the water inlet of the water immersion tank 20, and the water outlet of the water immersion tank 20 is connected with the second-level water outlet. The water inlet of the backwater poo...

Embodiment 3

[0032] kudzu rope production systems such as image 3 Shown: include the immersion tank 10 that is used to soak kudzu vine bark that is arranged in order, the water immersion tank 20 that is used to soak the kudzu vine bark after soaking and peeling, the rubbing tank 30 that scrubs the peeled kudzu vine bark by rubbing, The kudzu vine bark fiber after rubbing and washing is carried out the wire hanger 40 of splitting and drying, and the weaving device 50 for weaving the kudzu vine bark fiber silk into rope; the water inlet of scrubbing tank 30 and the clear water tank 60 outlet of storing clear water Connected, the water outlet of the scrub tank 30 is connected with the water inlet of the first-level backwater pool 71, the water outlet of the first-level backwater pool 71 is connected with the water inlet of the water immersion tank 20, and the water outlet of the water immersion tank 20 is connected with the second-level water outlet. The water inlet of the backwater pool 72 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com