Gas-liquid distributor used for wood tar fluidized bed reactor

A technology of fluidized bed reactor and gas-liquid distributor, which is used in hydrocarbon oil cracking, petroleum industry, etc., can solve the problems of high probability of catalyst backflow, affecting the return sealing effect, large jumping of the anti-return ball, etc., and achieves gas-liquid diffusion. Wide area, safe and reliable use, and the effect of expanding the diameter of bubble flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

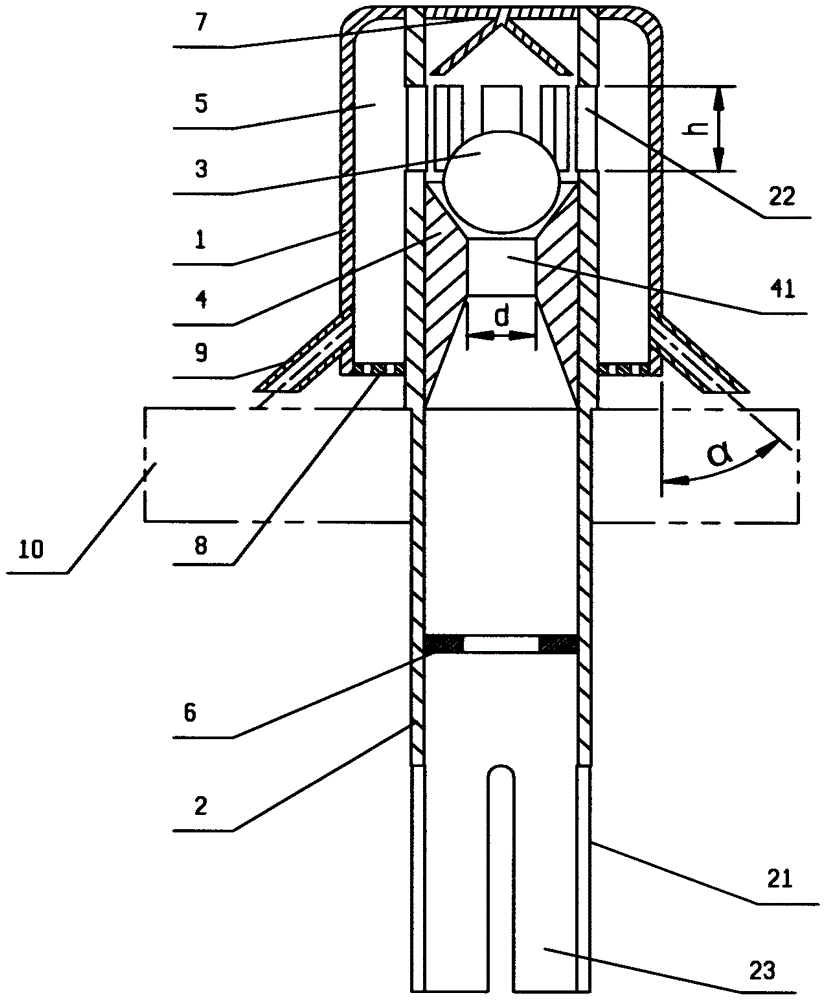

[0026] The gas-liquid distributor for wood tar ebullating bed reactor of the present invention will be further described below in conjunction with the accompanying drawings.

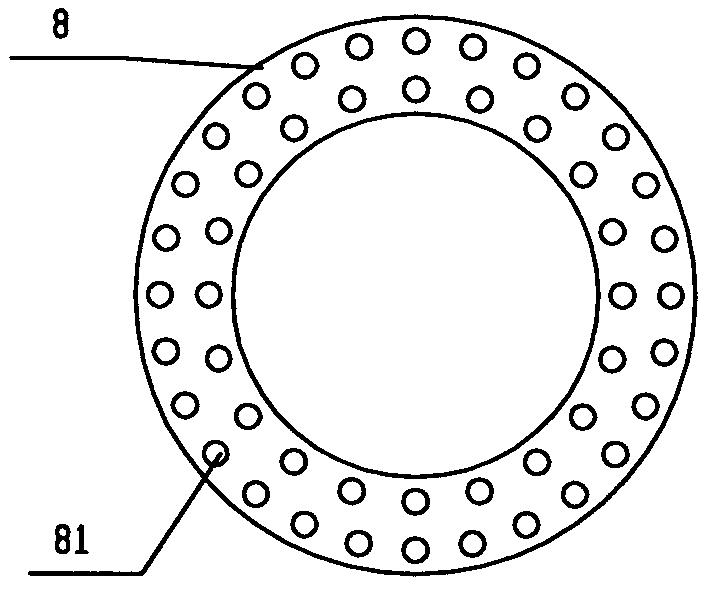

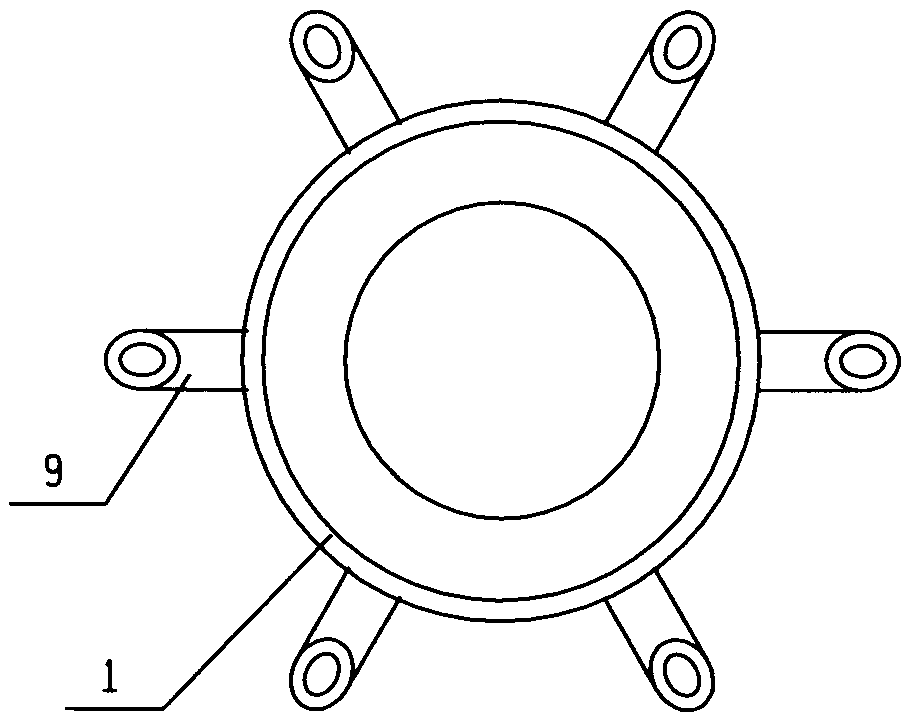

[0027] see figure 1 , figure 2 , the gas-liquid distributor used in the wood tar ebullated bed reactor of the present invention is mainly composed of a central tube 2, a bubble cap 1, a non-return ball 3, a conical ball seat 4 and a limit seat 7; the bubble cap 1 is an open bottom The cylinder of the mouth is covered on the upper end of the center tube 2 and is fixedly connected with the center tube. The limit seat 7 is arranged on the top of the bubble cap 1 and is located in the center tube 2. The tube wall of the center tube below the limit seat 7 is provided with The strip-shaped hole 22 is used as a material outlet, and the central tube wall below the strip-shaped hole 22 is provided with a conical ball seat 4. Seat 7, non-return ball 3 and conical ball seat 4 are arranged coaxially, an annular p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com