Evaporating and crystallizing zero-discharge treatment system and method for high-COD waste water

A treatment system, evaporation and crystallization technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of increased energy consumption, reduced heat exchange efficiency of heat exchange equipment, inability to Achieve zero emission and other issues, achieve stable operation, high cleaning efficiency, and high preheating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Adopt the above-mentioned processing system and processing method of the present invention to process the ethylene alkali slag waste liquid that certain enterprise produces, waste liquid amount 25m 3 / h, its water quality is shown in Table 1:

[0042] Table 1 Water quality of ethylene alkali slag waste liquid in an enterprise

[0043]

[0044]

[0045] Note: The salt contained is divided into sodium sulfate.

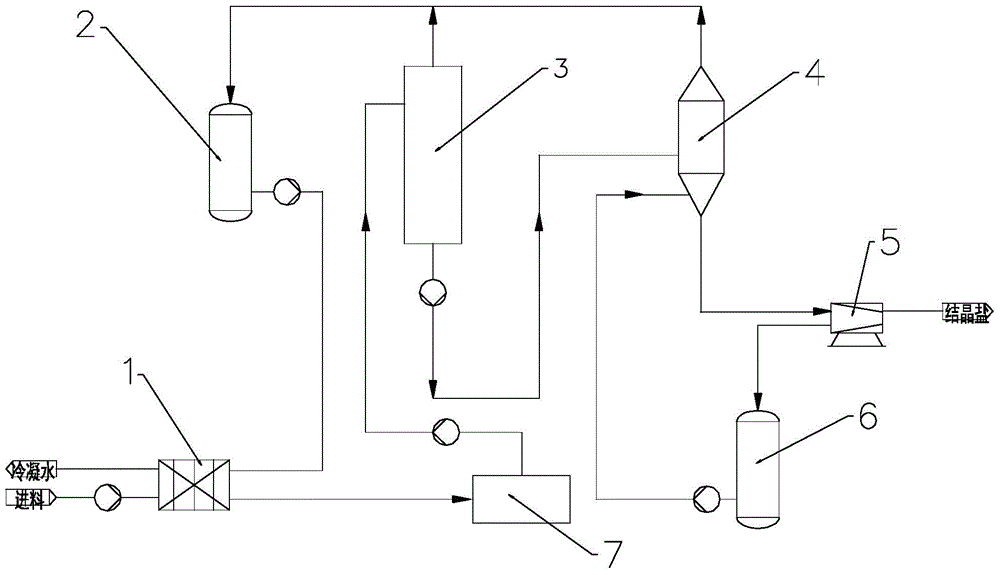

[0046] It can be seen from Table 1 that the wastewater has the characteristics of high organic matter content, complex composition and refractory degradation. According to the characteristics of waste water, the present invention adopts such as figure 1 The shown treatment process, that is, the conditioning unit 7 is arranged between the preheater 1 and the evaporator 3 . Its processing includes:

[0047] 1) The waste lye with an inlet water temperature of 30°C is lifted by the feed pump and enters the preheater 1 to be preheated to 80°C, then enters the...

Embodiment 2

[0054] The high-salt wastewater obtained by a chemical enterprise through pretreatment, membrane concentration, and salt separation is treated by using the treatment system and treatment method as described above in the present invention, and the amount of salt water is 150m 3 / h, its water quality is shown in Table 2:

[0055] Table 2 Salt water quality of a chemical enterprise

[0056]

[0057] Note: The salt contained is divided into sodium sulfate.

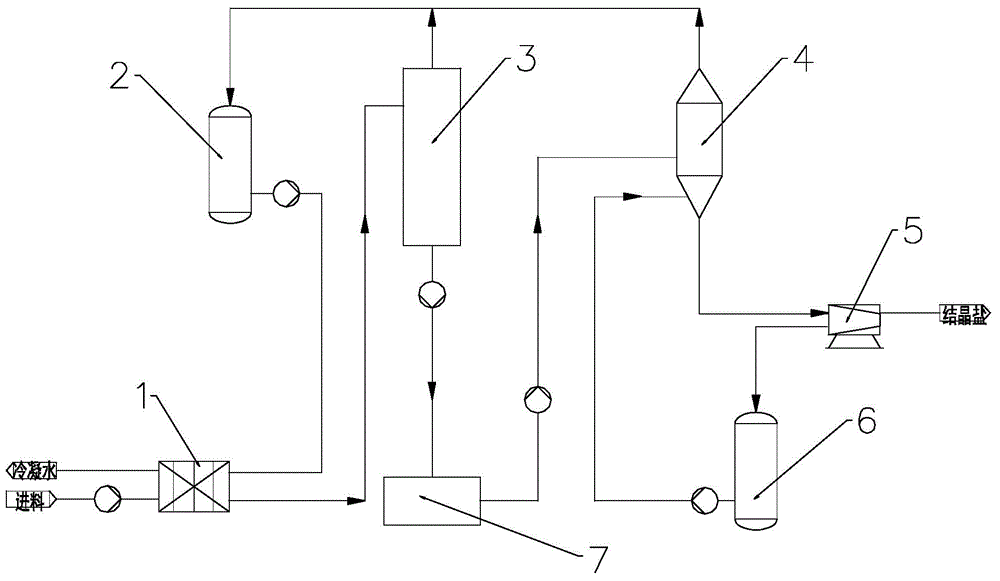

[0058] According to the water quality characteristics of the salt water of table 2, the present embodiment adopts such as figure 2 The treatment process shown, that is: the conditioning unit 7 is arranged between the water outlet of the concentrated solution of the evaporator 3 and the water inlet of the crystallizer 4, and the present embodiment adopts three such as figure 2 Wastewater is treated in the manner of the treatment system shown, and the treatment process of a single treatment system includes:

[0059] 1) T...

Embodiment 3

[0065] Adopt the above-mentioned treatment system and treatment method of the present invention to treat the high-salt wastewater obtained after the ion-exchange regeneration waste liquid of an enterprise is pretreated and membrane-concentrated, and the amount of salt water is 16m 3 / h, its water quality is shown in Table 3:

[0066] Table 3 Salt water quality of an enterprise

[0067]

[0068] Note: The salt content is mainly sulfur calcium chloride, magnesium chloride, sodium chloride.

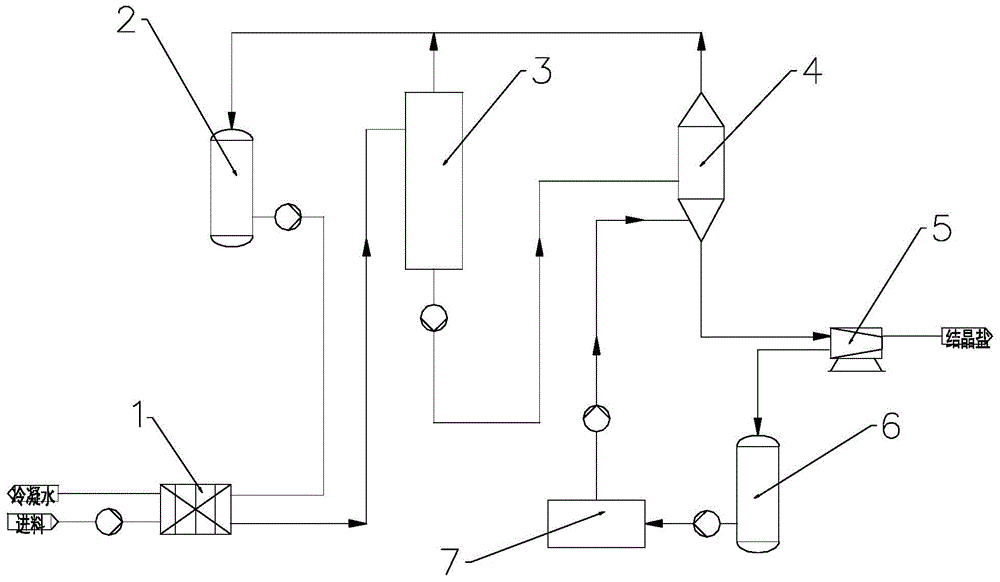

[0069] According to the water quality characteristics of the salt water of table 3, the present embodiment adopts such as image 3 The shown treatment process, that is: the conditioning unit 7 is located between the water outlet of the mother liquor tank 6 and the water inlet of the crystallizer 5, and the treatment process of the treatment system includes:

[0070] 1) The waste lye with an inlet water temperature of 30°C is lifted by the feed pump into the preheater 1 to be preheated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com