Positioning die

A technology for positioning molds and positioning rods, which is applied in the direction of manufacturing tools and presses, etc. It can solve the problems of displacement deviation, failure to meet the use requirements, and high product scrap rate, so as to prevent displacement deviation, meet production needs, and achieve good production results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

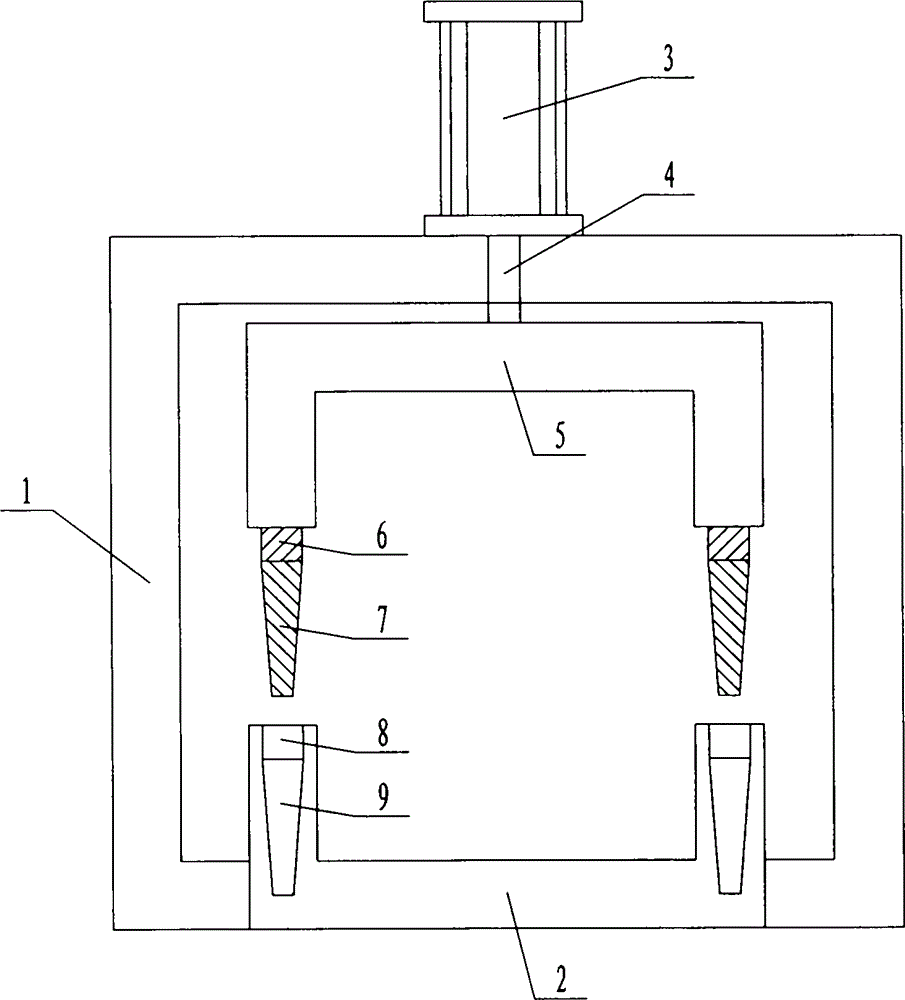

[0009] Such as figure 1 As shown, the positioning mold includes: a frame 1, a lower mold 2 is fixedly arranged at the lower end of the frame 1, and a cylinder 3 is arranged at the upper end of the frame 1, and the piston rod 4 of the cylinder 3 passes through The frame 1 is connected with the upper die 5, and several cylindrical positioning rods 6 and conical guide pins 7 connected with the lower ends of the cylindrical positioning rods 6 are uniformly arranged around the upper die 5. A positioning hole 8 cooperating with the cylindrical positioning rod 6 and a tapered guiding hole 9 communicating with the lower end of the positioning hole 8 are provided, and the tapered guiding hole 9 cooperates with the tapered guiding thimble 7 .

[0010] When the above-mentioned positioning mold is used, when the mold is closed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com