One-step process prepares the method for polylactic acid film

A technology of polylactic acid and film, which is applied in the field of preparing polylactic acid film by one-step method, can solve the problems of performance degradation, increase of polylactic acid film preparation cost, increase of polylactic acid processing times of polylactic acid film, etc. Secondary processing steps, the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

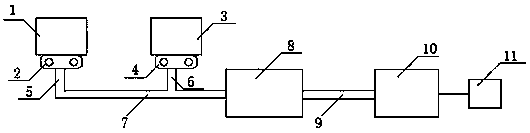

[0026] The polylactic acid melt obtained after the polymerization in the polylactic acid polymerization reaction device 1 is continuously output through the high-pressure melt delivery metering pump 2, and the melt is continuously input through the delivery pipeline 5 and the delivery pipeline 7 with heating and heat preservation functions. In the mixing device 8, at the same time, the toughening agent melt polymerized in the toughening agent polymerization reaction device 3 is continuously output by the high-pressure melt delivery metering pump 4, and passed through the delivery pipeline 6 with heating and heat preservation functions. In the melt mixing device 8 that is continuously input into the delivery pipeline 7, the mass ratio of the polylactic acid melt and the toughening agent melt is controlled to be 97:3, and the polylactic acid and the toughening agent are mixed uniformly by the melt mixing device 8 to obtain a toughening agent. Toughened modified polylactic acid me...

Embodiment 2

[0029] The polylactic acid melt obtained after the polymerization in the polylactic acid polymerization reaction device 1 is continuously output through the high-pressure melt delivery metering pump 2, and the melt is continuously input through the delivery pipeline 5 and the delivery pipeline 7 with heating and heat preservation functions. In the mixing device 8, at the same time, the toughening agent melt polymerized in the toughening agent polymerization reaction device 3 is continuously output by the high-pressure melt delivery metering pump 4, and passed through the delivery pipeline 6 with heating and heat preservation functions. In the continuous input melt mixing device 8 with the delivery pipeline 7, the mass ratio of the polylactic acid melt and the toughening agent melt is controlled to be 85:15, and the polylactic acid and the toughening agent are mixed uniformly by the melt mixing device 8 to obtain a toughening agent. Toughened modified polylactic acid melt, and t...

Embodiment 3

[0032]The polylactic acid melt obtained after the polymerization in the polylactic acid polymerization reaction device 1 is continuously output through the high-pressure melt delivery metering pump 2, and the melt is continuously input through the delivery pipeline 5 and the delivery pipeline 7 with heating and heat preservation functions. In the mixing device 8, at the same time, the toughening agent melt polymerized in the toughening agent polymerization reaction device 3 is continuously output by the high-pressure melt delivery metering pump 4, and passed through the delivery pipeline 6 with heating and heat preservation functions. In the melt mixing device 8 that is continuously input into the delivery pipeline 7, the mass ratio of the polylactic acid melt and the toughening agent melt is controlled to be 90:10, and the polylactic acid and the toughening agent are mixed uniformly by the melt mixing device 8 to obtain a toughening agent. Toughened modified polylactic acid me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com