Ring-removing mechanism for single-head large-cylinder-diameter nodular cast iron piston ring

A technology of nodular cast iron and piston rings, which is applied in the field of runner separation mechanisms, can solve the problems of high labor intensity, deformation of piston ring blanks, high scrap rate, etc., and achieve simple and reliable mechanism structure, convenient ring removal work, and reduced labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

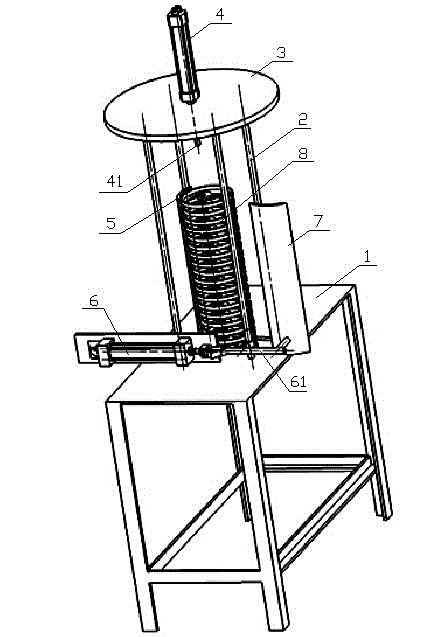

[0008] like figure 1 As shown, the present invention vertically fixes four support rods 2 on the workbench 1, supports a circular cover 3 arranged horizontally above the four support rods 2, and connects a vertical cover 3 at the center of the cover 3. The telescopic rod 41 of the vertical impact cylinder 4 is inserted into the center hole of the cover plate 3 .

[0009] A rear baffle 5 is vertically arranged inside the space surrounded by four support rods 2 , and the lower end of the rear baffle 5 is fixedly welded on the workbench 1 .

[0010] A horizontal compression cylinder 6 is also fixed on the workbench 1, and a front baffle 7 is fixedly connected to the end of the telescopic rod 61 of the horizontal compression cylinder 6.

[0011] When the horizontal compression cylinder 6 is tightened, the telescopic rod 61 brings back the front baffle 7, so that the front baffle 7 and the rear baffle 5 embrace the piston ring arranged between the front baffle 7 and the rear baffl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com