Vibration feeding device for crude ore desliming and dressing

A technology of vibrating feeding and vibrating feeding machine, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of waste of energy resources, high cleaning labor intensity, and accumulation of mud ore, etc. The channel is smooth, the secondary crushing volume is reduced, and the production cost is saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

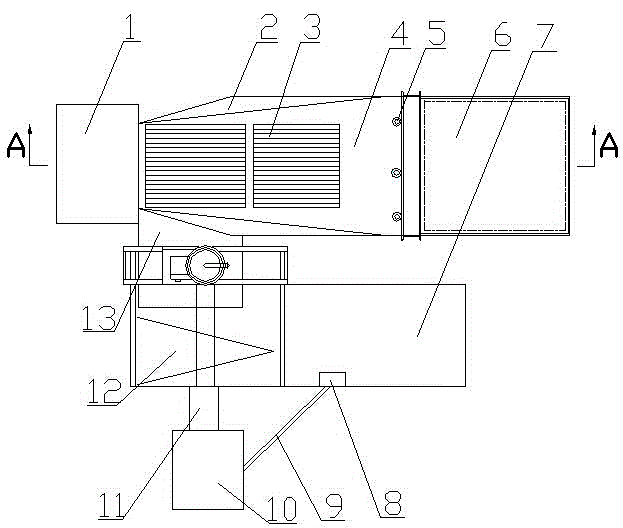

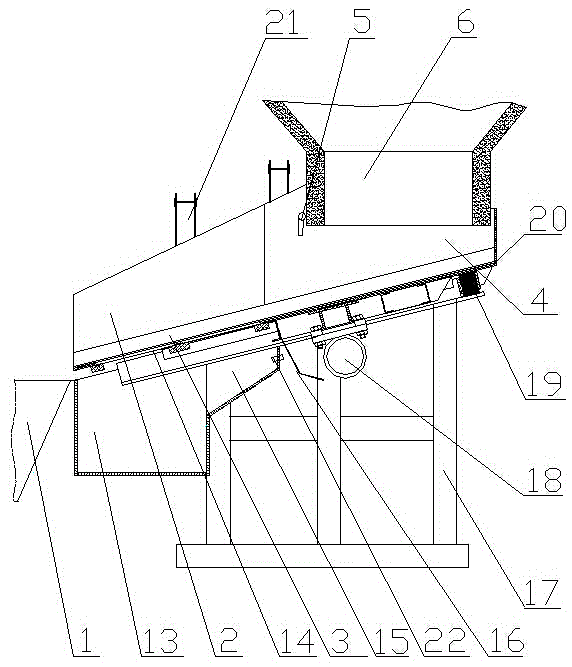

[0021] As shown in the attached figure: a vibrating feeding device for coarse ore desliming and screening, including a coarse ore bin 6, a vibrating feeder 2, a first water washing device 5, a jaw crusher 1, a material guide Device 13, spiral classifier 12, ball mill 10, vibrating feeder 2 is installed on the lower left side of the rough ore bin 6, the first water flushing device 5 is installed above the connection between the rough ore bin 6 and the vibrating feeder 2, the jaw The type crusher 1 is installed on the left side of the vibrating feeder 2, and the spiral classifier 12 is placed on the front side of the vibrating feeder 2. What the spiral classifier 12 adopts is the FG-75 type spiral classifier with a length of 12 meters. Material guiding device 13 is installed below vibrating feeder 2, and is connected with screw classifier 12, and the groove body slope of material guiding device 13 is 35%, is beneficial to improving material guiding efficiency; The spiral classif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com