Horizontal automatic skewer machine

A skewer machine and automatic technology, applied in the direction of baking, cleaning/oiling machinery for baking, food ovens, etc., can solve the threat to the health of operators and customers, affect the atmospheric environment, cannot spread materials, brush Oil and other problems, to prevent heat loss and waste, wide range of heat radiation, and solve the problem of oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

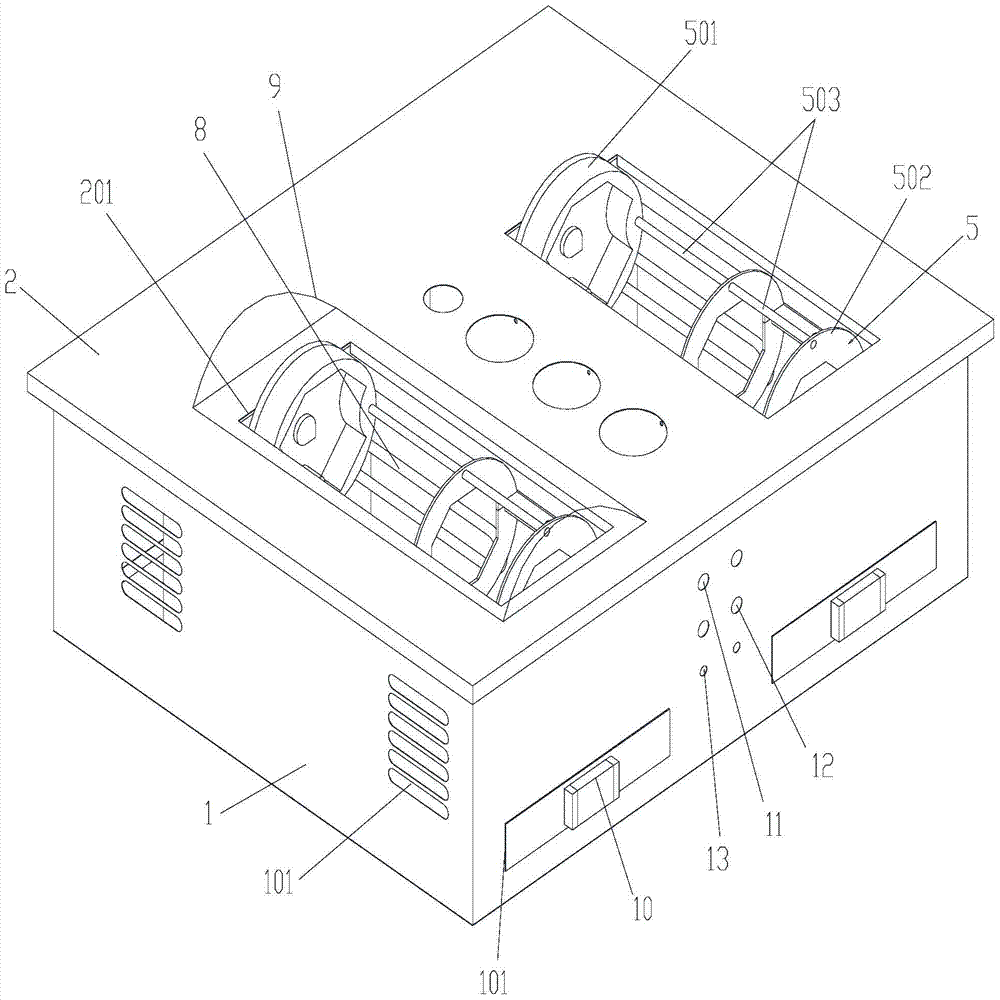

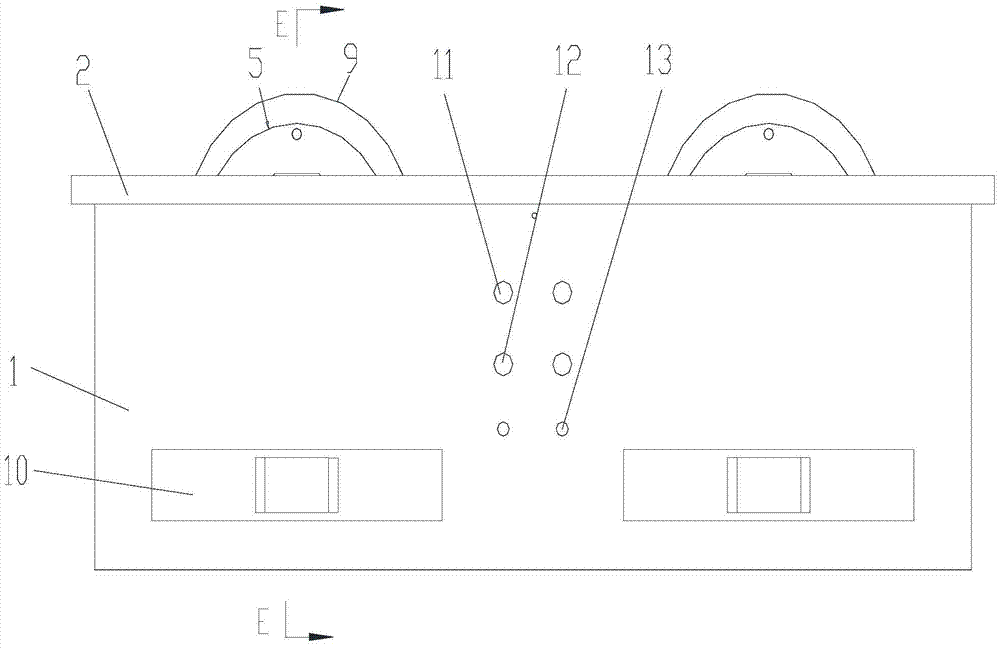

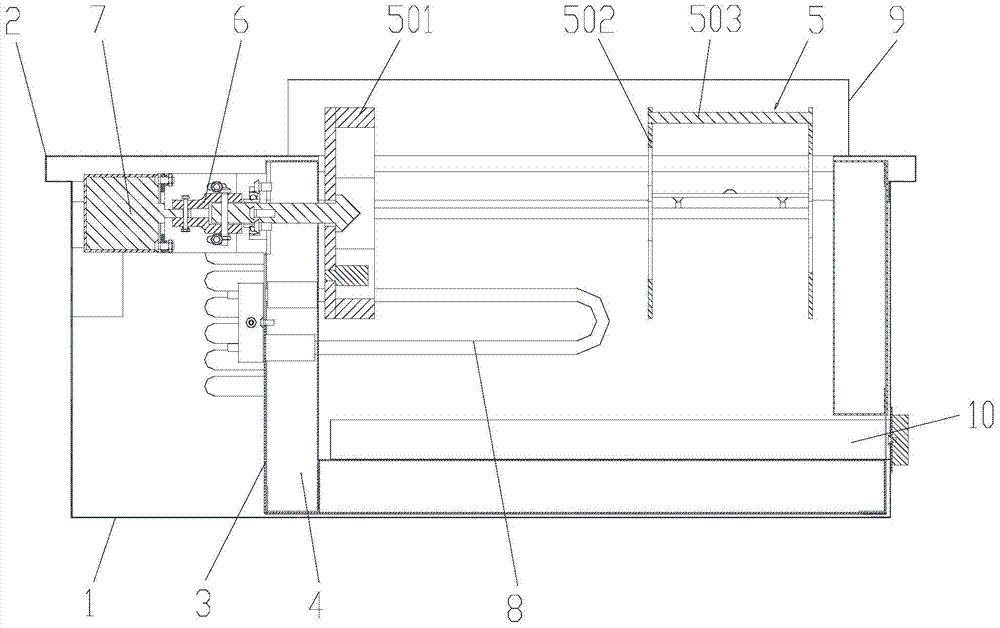

[0021] Attached below Figure 1-3 Embodiments of the present invention are described.

[0022] The horizontal automatic grilling machine has a shell 1 and a shell cover 2. The shell cover 2 is placed on the upper surface of the shell 1. A plurality of brackets 3 are arranged in parallel inside the shell 1. In this embodiment, there are two Take the bracket 3 as an example for specific description, such as figure 1 , 3 As shown, the bracket 3 is provided with a heat-insulating interlayer 4. Preferably, the heat-insulating interlayer 4 is made of high-efficiency heat-insulating materials to effectively isolate the baking area from other areas, ensure the effective use of heat energy, and ensure that the periphery and the shell 1 Such as easy-to-contact parts will not generate high temperature, ensuring the safe use of operators; the shell cover 2 is provided with a rectangular hole 201 facing each bracket 3, and the inside of the two brackets 3 is provided with a roller for pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com