A kind of tobacco processing production method

A production method and tobacco technology, applied in the field of tobacco, can solve the problems of inflexibility, fixed process, and inability to meet the production of special cigarettes, etc., and achieve the effect of flexible combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

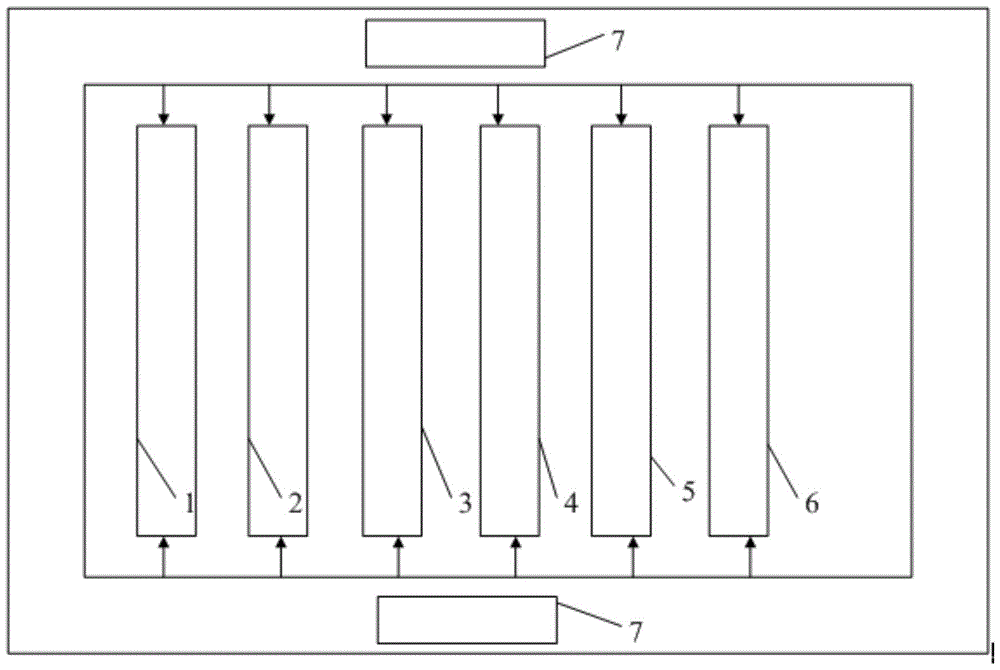

Embodiment 1

[0044] see figure 1 , is a schematic diagram of an embodiment of the device used in a tobacco processing and production method in the present invention, including a loose flake moisture regain processing module 1, a leaf moistening and feeding processing module 2, a shredded leaf processing module 3, a shredded leaf drying processing module 4, a blending Equipped with flavoring processing module 5 and burley tobacco processing module 6 six modules, and mobile leaf storage cabinet 7. The mobile leaf storage cabinet 7 is provided with several, arbitrarily connected to the above six processing modules, and the feeding and discharging storage of each module is realized by the mobile leaf storage cabinet 7, and the mobile leaf storage cabinet 7 can be pulled to Arbitrarily specify the position, so as to realize the arbitrary arrangement and combination of each processing module. Wherein, one of the two modules of the pine flake moisture regaining processing module 1 or the leaf mo...

Embodiment 2

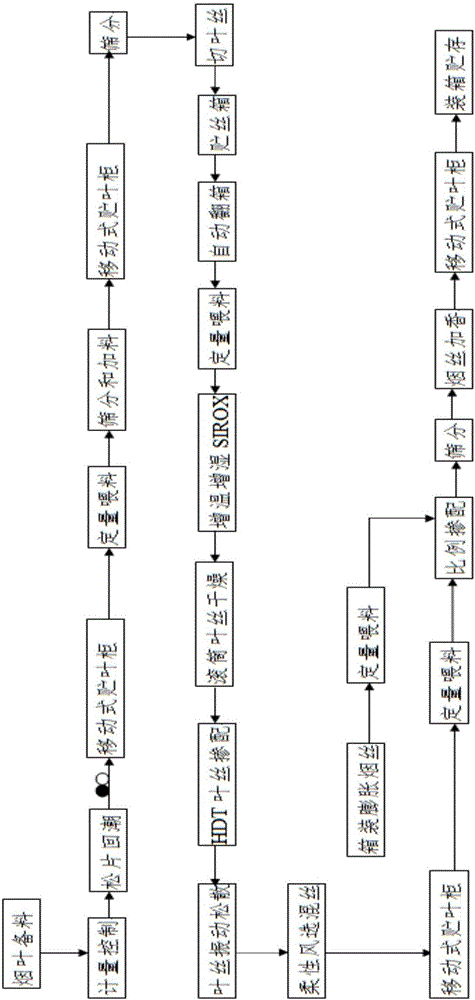

[0075] Such as figure 2 , a kind of tobacco processing production method that the embodiment of the present invention provides, concrete steps are as follows:

[0076] 101. Obtain processing characteristics and sequence characteristics according to the technological requirements of the cigarettes to be produced;

[0077] Because the present invention is just to solve the shortcomings of fixed and inflexible procedures in the prior art, so for more flexible, more convenient and quick production, firstly, according to the specific process requirements of the cigarette to be produced, obtain the cigarette’s Processing features and timing features, that is, to obtain some processing functions and processing sequences required in the production and processing of the cigarette, such as the processing method and processing sequence required in the processing of a certain cigarette.

[0078] 102. Select a number of processing modules according to the processing characteristics as a ...

Embodiment 3

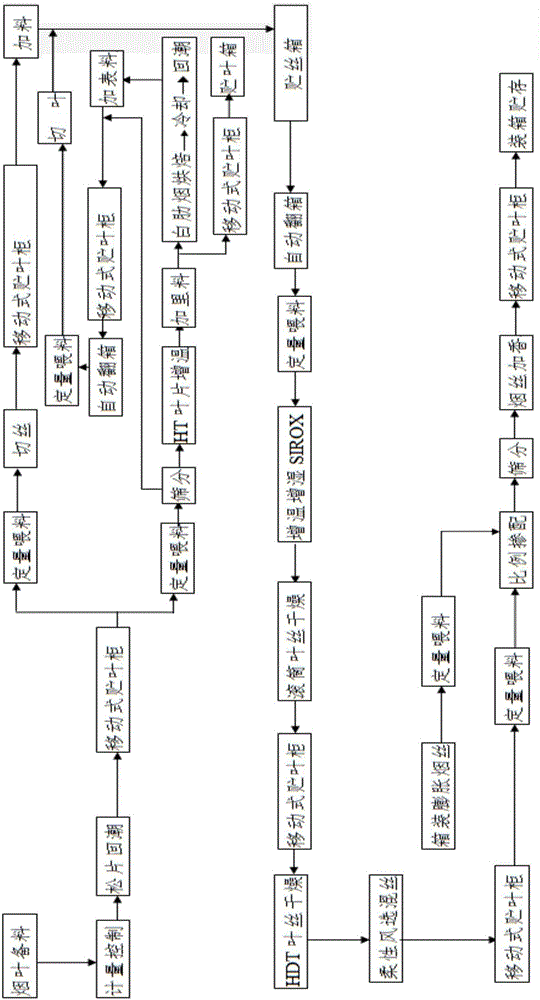

[0084] Such as image 3 , is a schematic diagram of the process flow of an embodiment of a tobacco processing and production method in the present invention, specifically the production process of a certain brand of mixed cigarettes, which belongs to the cigarette manufacturing process with special production process requirements: mixed cigarettes have two main formulas , one is flue-cured tobacco leaves, and the other is Burley tobacco leaves. Burley tobacco leaves and flue-cured tobacco leaves should be fed separately. Burley tobacco leaves can be processed first, or flue-cured tobacco leaves can be processed first. In this embodiment, the Burley tobacco leaves are processed at first, and after the Burley tobacco is prepared according to the formula sheet, the production starts. The first step of production is to place the tobacco leaves on the feeding belt. The feeding belt is equipped with a metering device, which can be calculated and controlled. Tobacco leaf flow rate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com