Induction Cooker Detection System

A detection system and induction cooker technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of waste, low safety, etc., and achieve the effects of improving production efficiency, improving comfort, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

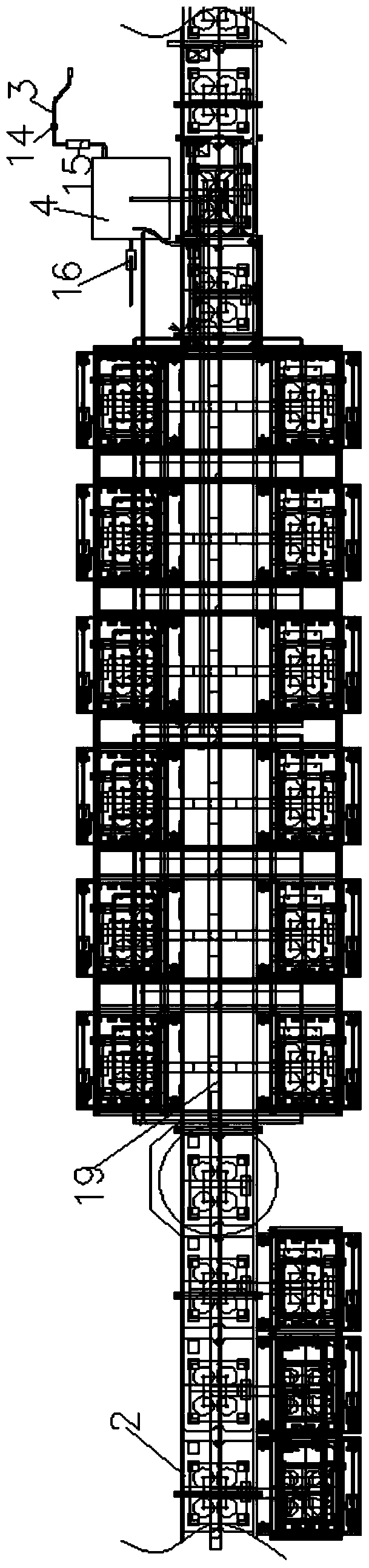

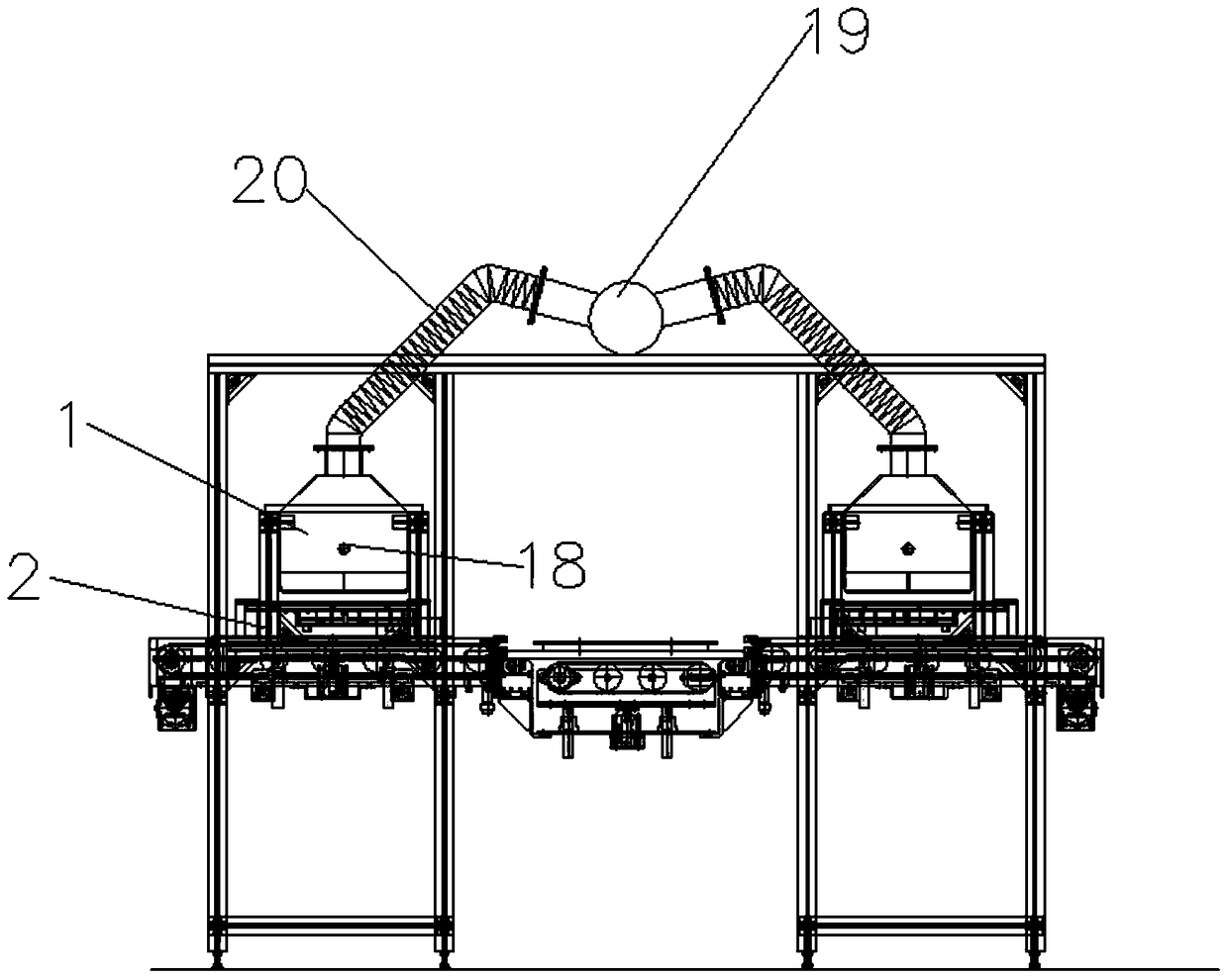

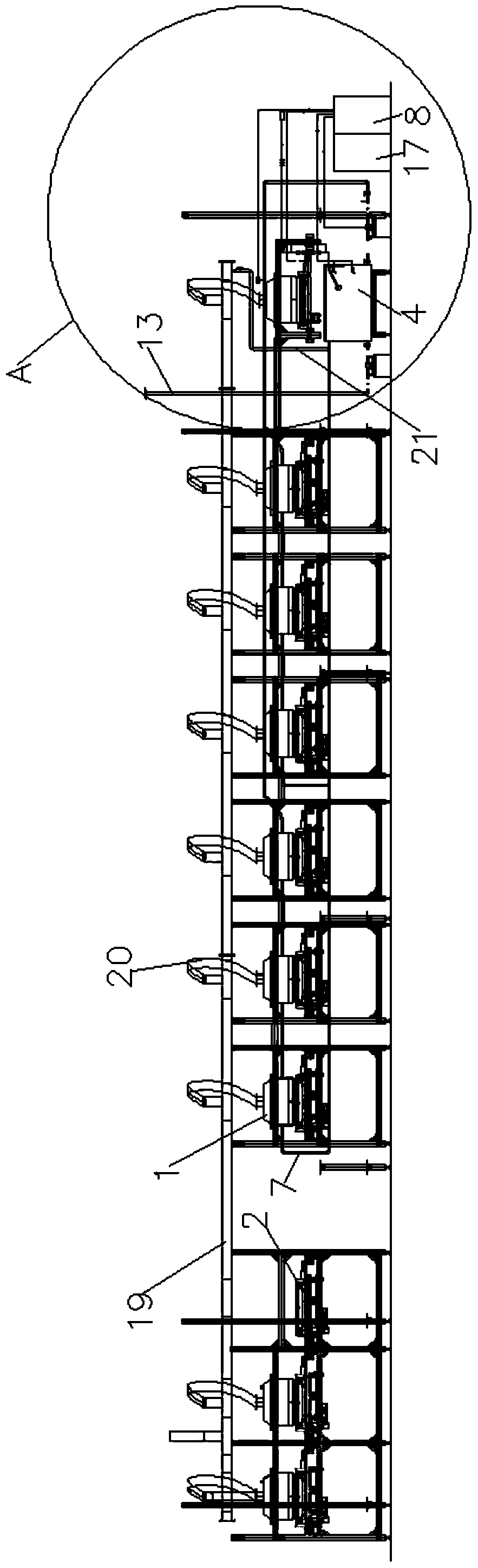

[0019] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

[0020] Such as Figure 1 to 4 As shown, the electromagnetic oven detection system of the present invention includes a DDC control cabinet 8, a water pump power cabinet 17, a water supply pipe 3, a water storage tank 4, a detection station, a variable frequency pressure pump 5, a tap water interface 12, a steam pipe 19, a water inlet pipe 6 and a return flow Pipe 7, the upper and lower parts of the water storage tank 4 are respectively provided with a high level sensor 9 and a low level sensor 10, the upper side wall of the water storage tank 4 is also provided with a water inlet and a water outlet, and a float level switch is also provided at the water inlet 11 is the ball valve control switch. This design makes the system have both electronic control and mechanical control, double insurance, greatly improving safety. The position of the water inlet is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com