A hydrogen concentration sensor based on the electrochemical principle of catalytic reaction

A concentration sensor and catalytic reaction technology, applied in the direction of material electrochemical variables, etc., can solve the problems of low measurement accuracy, inability to continuously monitor hydrogen on-line, and no devices, etc., and achieve the effects of strong selectivity, fast response time, and small measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

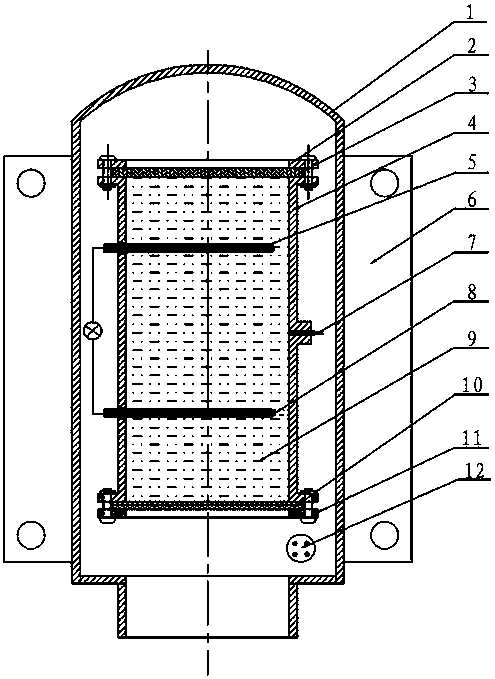

[0024] Such as figure 1 As shown, a hydrogen concentration sensor based on the electrochemical principle of catalytic reaction, including a pressure balance membrane 3, an inner shell 4, a counter electrode 5, a working electrode 8, a concentrated sulfuric acid electrolyte 9, a hydrogen semipermeable membrane 10 and a signal connector 12 , wherein the material of the inner shell 4 is polytetrafluoroethylene, the upper and lower ends of the inner shell 4 are open, the pressure balance membrane 3 is fixed on both ends of the inner shell 4 and closes the upper end of the inner shell 4 Opening, the hydrogen semi-permeable membrane 10 is fixed on the lower two ends of the inner shell 4 and closes the opening at the lower end of the inner shell 4 . In this embodiment, the area between the pressure balance membrane 3 , the inner casing 4 and the hydrogen semipermeable membrane 10 constitutes an electrolyte cavity, and the concentrated sulfuric acid electrolyte 9 is filled in the elec...

Embodiment 2

[0028] The present embodiment makes the following further limitations on the basis of Embodiment 1: the present embodiment also includes a temperature measuring element 7, wherein the temperature measuring element 7 passes through the inner shell 4 and its temperature sensing end is connected to the concentrated sulfuric acid electrolyte 9 touch.

Embodiment 3

[0030]This embodiment makes the following further limitations on the basis of embodiment 1 or embodiment 2: this embodiment also includes an upper sealing cover plate 2 and a lower sealing cover plate 11, and both the upper sealing cover plate 2 and the lower sealing cover plate 11 are It is circular. The inner shell 4 of this embodiment is cylindrical, and the upper and lower ends of the inner shell 4 protrude outward to form a ring-shaped positioning platform. The upper end surface contacts and is pressed down by the upper sealing cover plate 2, and the circumferential edge of the hydrogen semipermeable membrane 10 is in contact with the lower end surface of the lower positioning platform of the inner shell 4 and is pressed and fixed by the lower sealing cover plate 11. In this embodiment, when the pressure balance membrane 3 and the hydrogen semi-permeable membrane 10 are fixed, the two are first laid flat and the circumferential edges of the two are in contact with the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com