Pure countercurrent compact type pipe folding economizer

A compact, economizer technology, used in tubular elements, fluid circulation arrangements, evaporators/condensers, etc., which can solve the problem of low overall heat exchange efficiency of economizers, low flow rate of working medium on the shell side, and large tube side space, etc. problems, to achieve the effect of fully utilizing the heat exchange area, matching the heat exchange process, and compacting the shell side space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

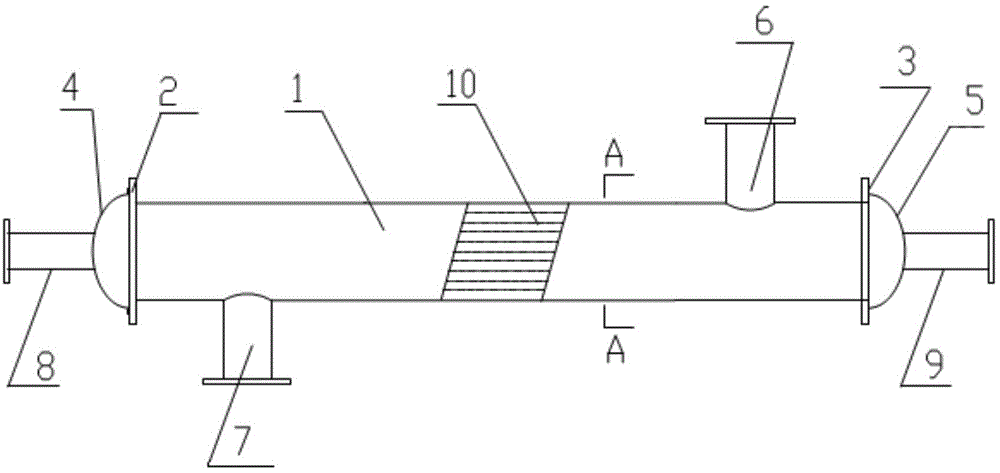

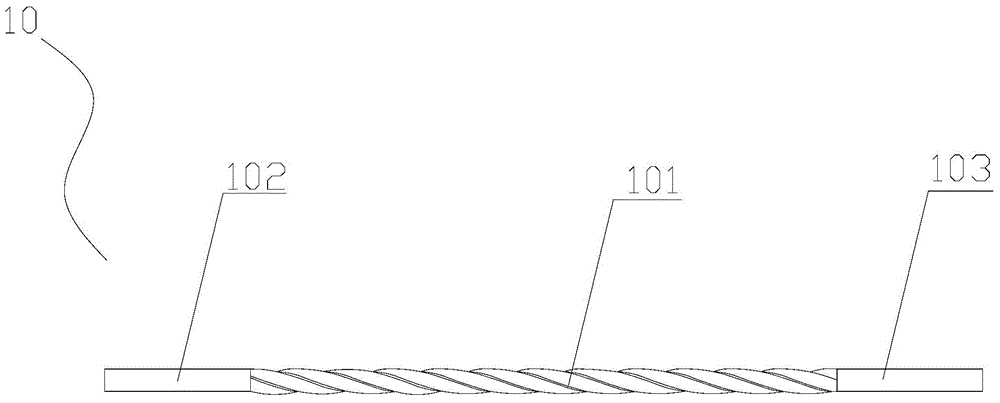

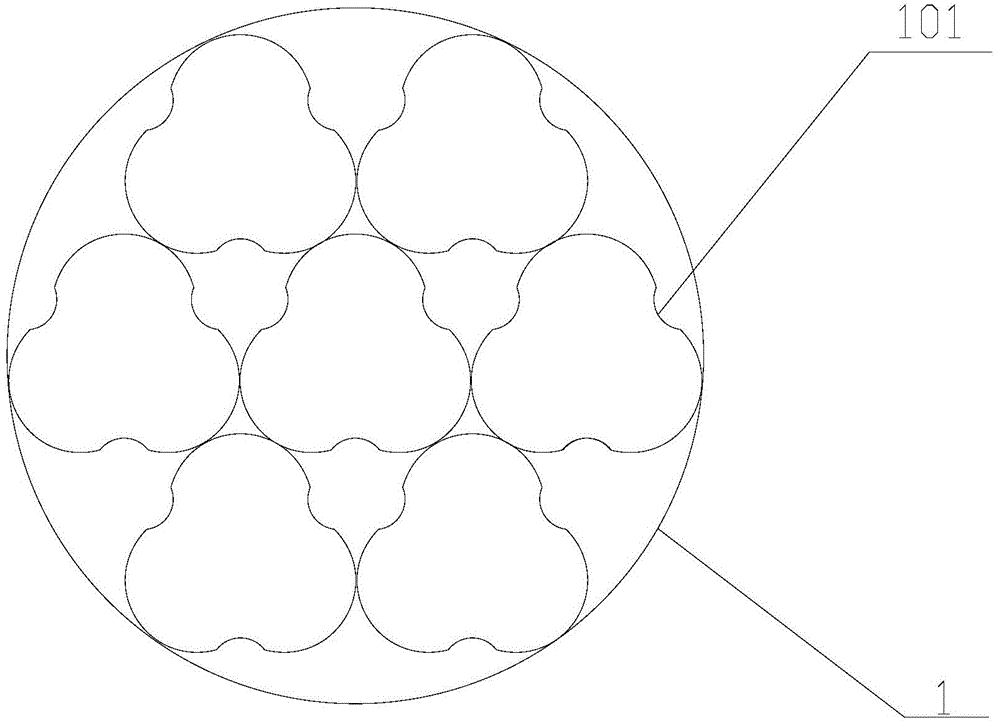

[0030] Please refer to figure 1 As shown, the pure countercurrent compact stacked tube economizer includes a shell 1, and the two ends of the shell 1 are respectively closed by a tube plate 2 and a tube plate 3 to form an accommodating space, and the shell 1 is installed with A plurality of heat exchange tubes 10, the outer sides of the tube sheet 2 and the tube sheet 3 are respectively fixedly connected to the head 4 and the head 5, and one end of the heat exchange tube 10 is welded to the tube sheet 2, and is fixedly connected to the sealing head 4 through the head 4. The tube side inlet 8 on the head 4 is connected, and the other end of the heat exchange tube 10 is welded on the tube sheet 3 , and communicates with the tube side outlet 9 fixedly connected to the head 5 through the head 5 . The upper and lower sides of the shell 1 are respectively fixedly connected with a shell-side inlet 6 and a shell-side outlet 7 communicating with the accommodation space, wherein the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com