Anti-loosening thread assembly

A technology of threaded components and threaded components, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of reduced reliability of tools, unreliable locking, and increase in size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

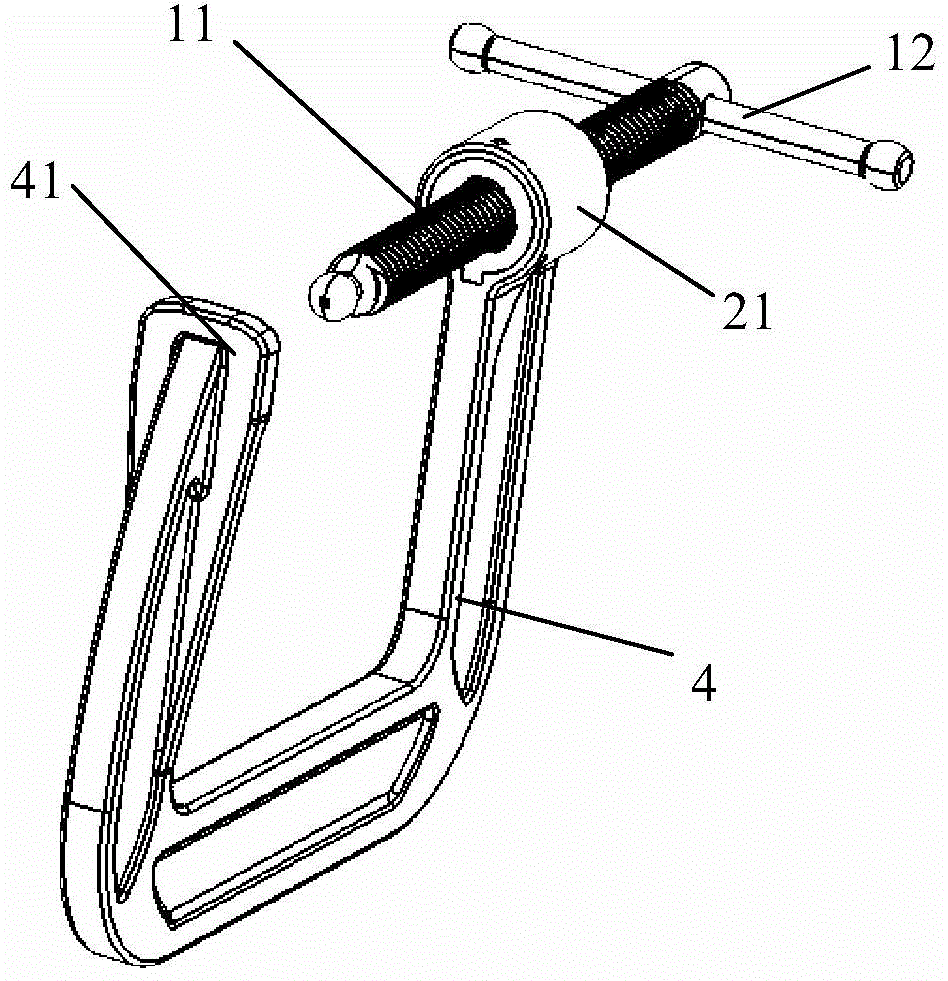

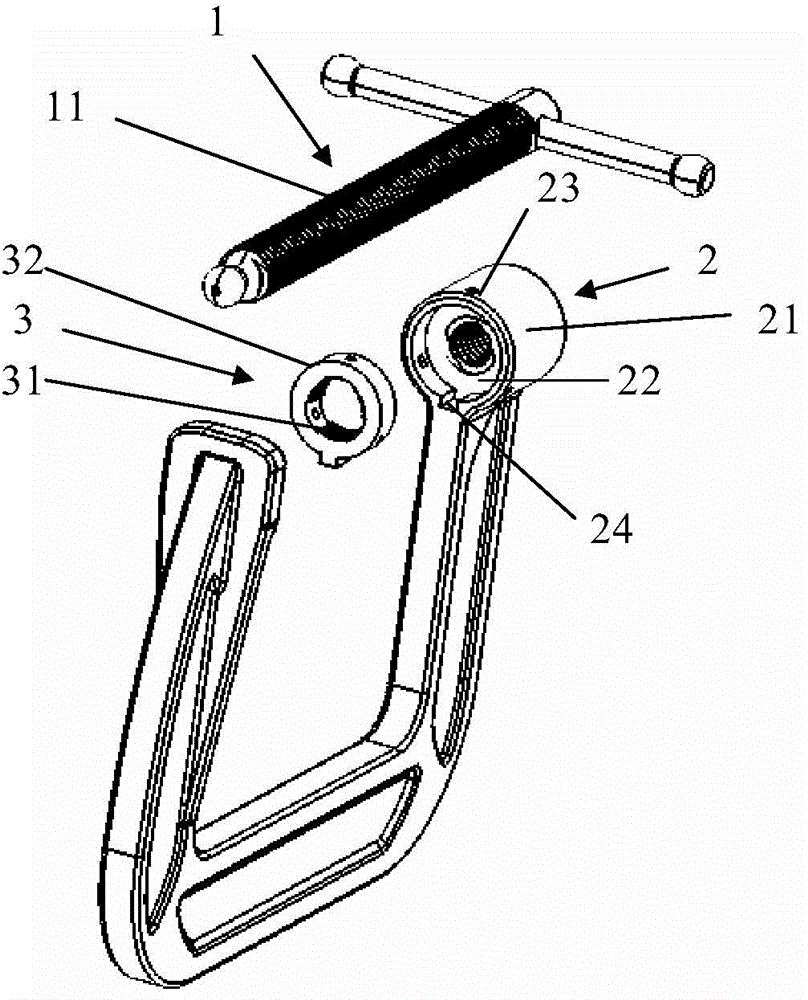

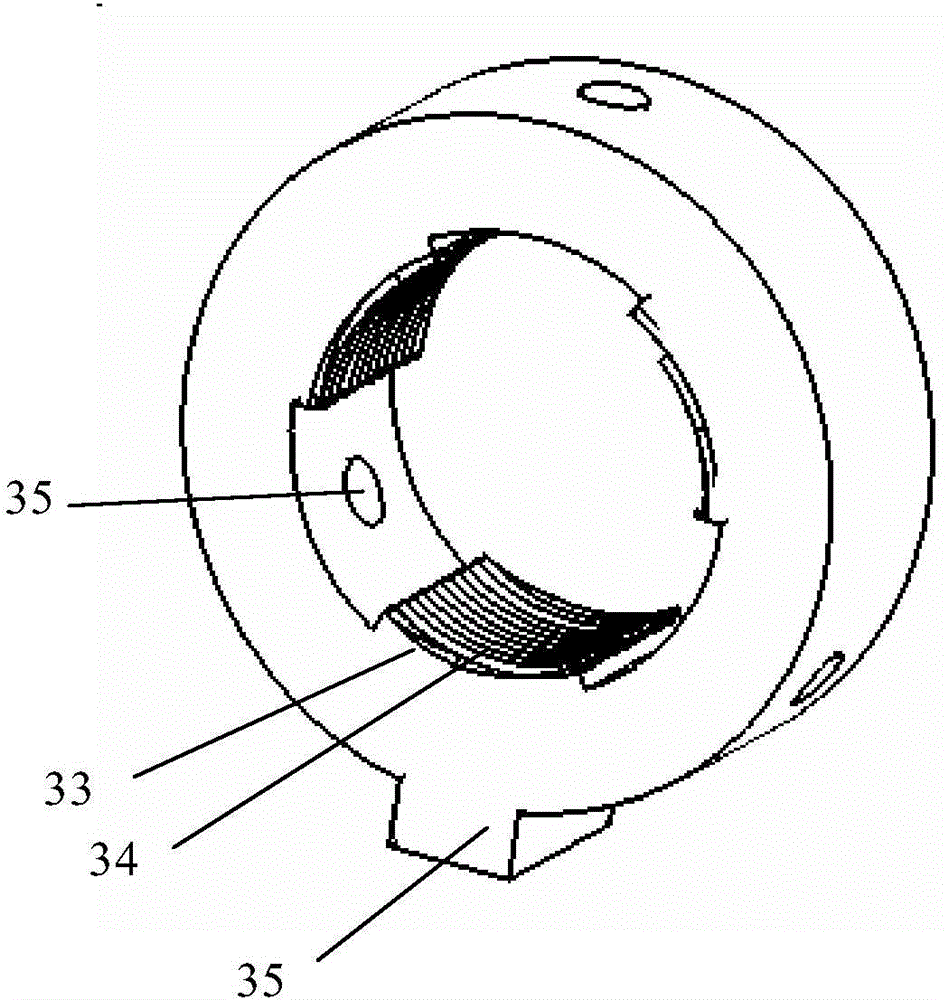

[0041] like Figure 1-14 The anti-loosening thread assembly shown is characterized in that it includes: an external threaded element 1 with an external thread, and a threaded element 2 with a thread that is adapted to the external threaded element, wherein the external threaded element 1 can be connected with the external thread The engagement of the thread moves relative to the threaded element, and the blocking element 3 arranged outside the external threaded element has a protrusion 31 on the inside of the blocking element, and there is a gap between the protrusion of the blocking element and the external threaded element. Under normal circumstances, the protrusion of the blocking element and the external threaded element The externally threaded components do not touch, and will not affect the normal use of the threaded components. When the externally threaded components are tilted under force, the externally threaded components contact the protrusions of the blocking elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com