A method of expansion cracking and anti-permeability for rapid tunneling of underground coal seam roadway

A technology of expansion cracking and roadway, which is applied in the field of expansion cracking and anti-reflection for rapid tunneling of underground coal seam roadways. It can solve the problems of easily damaged roadway, high price, and insufficient seam width, etc., and achieve safe and reliable construction process, convenient manual operation, and improved ventilation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

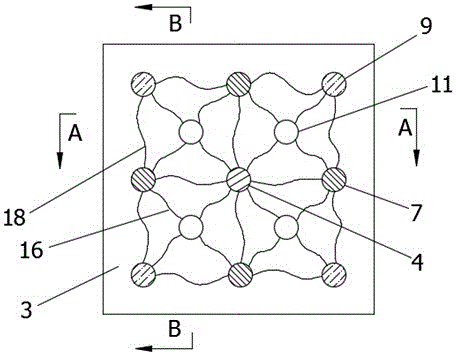

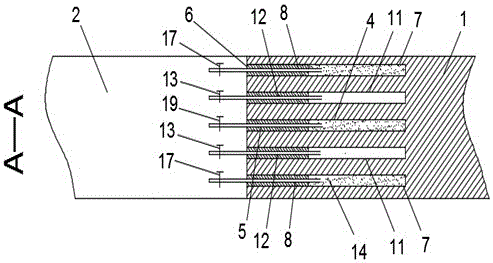

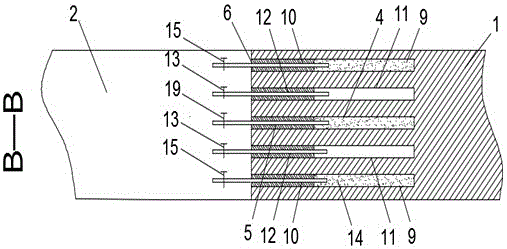

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] Such as figure 1 As shown, a hole is drilled at the geometric center position of the front end 3 of the roadway 2 in the coal seam 1 and a first expansion hole 4 is constructed, a first grouting pipe 5 is inserted into the first expansion hole 4, and polyurethane 6 is used for the first expansion hole 4. The orifice of the crack hole 4 is sealed; a second expansion hole 7 is constructed directly above, directly below, directly to the left and directly to the right of the first expansion hole 4, and a second expansion hole 7 is inserted into each second expansion hole 7 respectively. A second grouting pipe 8 is used to seal the opening of each second expansion hole 7 with polyurethane 6; a third expansion hole 7 is constructed directly above and directly below the second expansion hole 7 at the same level as the first expansion hole 4. Expansion hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com