Drilling and Completion Method of Coalbed Gas Horizontal Branch Well

A technology for horizontal branch wells, drilling and completion, applied in drilling equipment and methods, wellbore/well components, drilling equipment, etc., can solve the problem of high cost of horizontal well branch drilling, increased open hole vacancy time, and impact on coalbed methane. Development efficiency and other issues, to achieve the effect of shortening the operation cycle, avoiding drilling swabbing, and reducing drilling risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

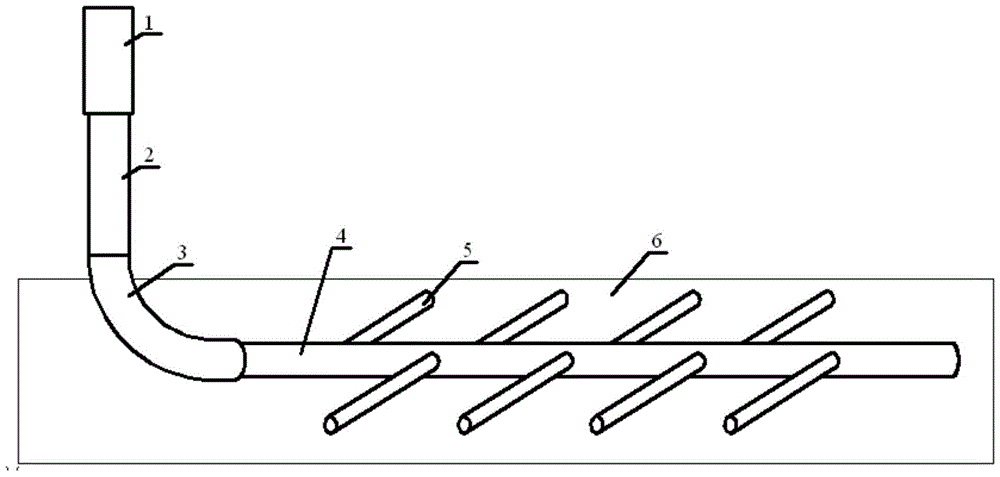

[0021] In the present invention, the conventional drilling tool assembly is used to complete the drilling of the first surface section and the second section of the horizontal well. After the drilling is completed, the casing is cemented. Casing directional drilling tool assembly drilling, after drilling to the designed well depth, the bottom hole directional drilling tool assembly is pulled out from the casing with a steel wire fishing device, and then the ultra-short radius drilling technology is used to drill branch wells, and finally the fish is drilled Bone type horizontal branch well.

[0022] The embodiment of the present invention provides a method for drilling and completing a coalbed methane horizontal branch well, such as figure 1 As shown, the method is implemented through the following steps:

[0023] Step 1: Complete the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com