Aluminum alloy outward opening window with good sealing performance

A sealing performance, aluminum alloy technology, applied in the direction of sealing devices, windows/doors, window/door frames, etc., can solve the problems of unsatisfactory thermal insulation and sealing effect, unfavorable thermal insulation and energy saving, poor sealing performance, etc., to ensure the thermal insulation effect. , The effect of reducing production cost and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

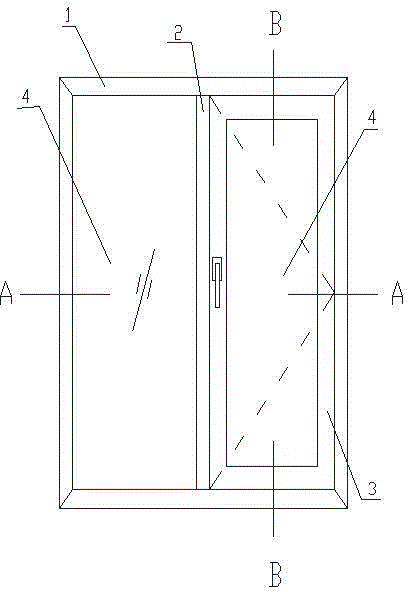

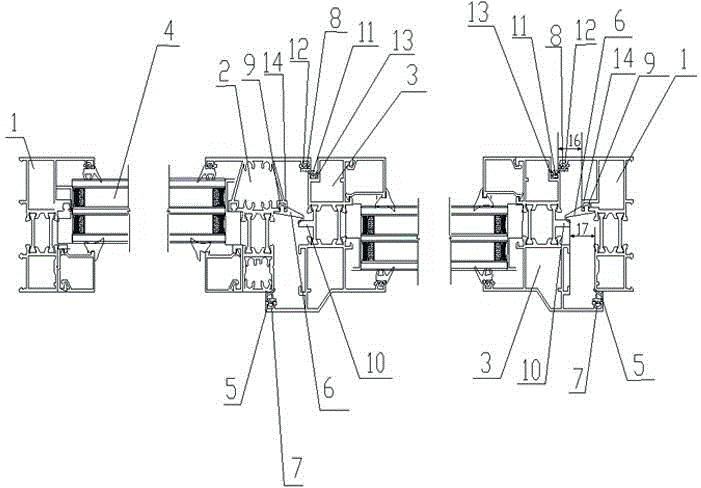

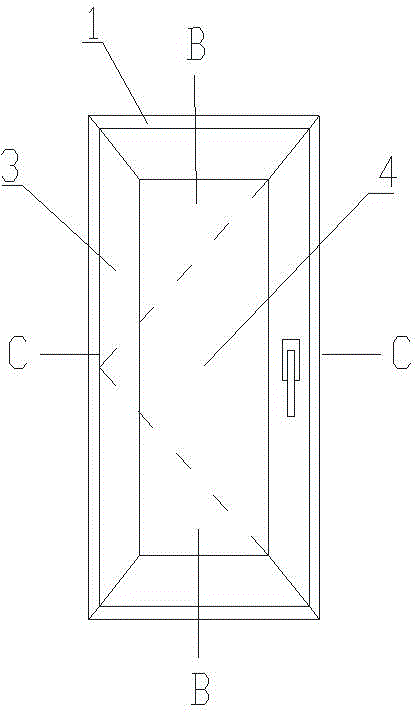

[0016] Such as image 3 , Figure 4 and Figure 5 Shown embodiment 2, this embodiment has only one opening window. It includes a frame 1 with a heat insulating strip in the middle, a fan frame 3 with a heat insulating strip in the middle and a hollow glass 4 . There are three seals at the fixed position and overlapping position of the fan frame 3 and the frame 1 respectively: two sealing strips A 8 and B 11 overlapped together on the indoor side, and the outdoor side is lapped on the outer side of the frame 1 and fixed on the The sealing rubber strip C5 in the groove 7 at the outer edge of the fan frame 3, and the equal pressure rubber strip D6 in the middle. Sealing strip A 8 is pressed and glued and fixed in the groove 12 at the inner edge of the frame 1 chamber, sealing strip B 11 is fixed in the groove 13 at the inner edge of the fan frame 3 chamber, and one end of the equal pressure strip D 6 It is fixed in the groove 9 on the boss 14 protruding from the inner side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com