Preparation method of anhydrous calcium sulfate whisker

An anhydrous calcium sulfate and whisker technology is applied in the field of preparing anhydrous calcium sulfate whiskers by one-step hydrothermal method, which can solve the problem of high industrial cost and achieve the effects of reducing production cost, simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

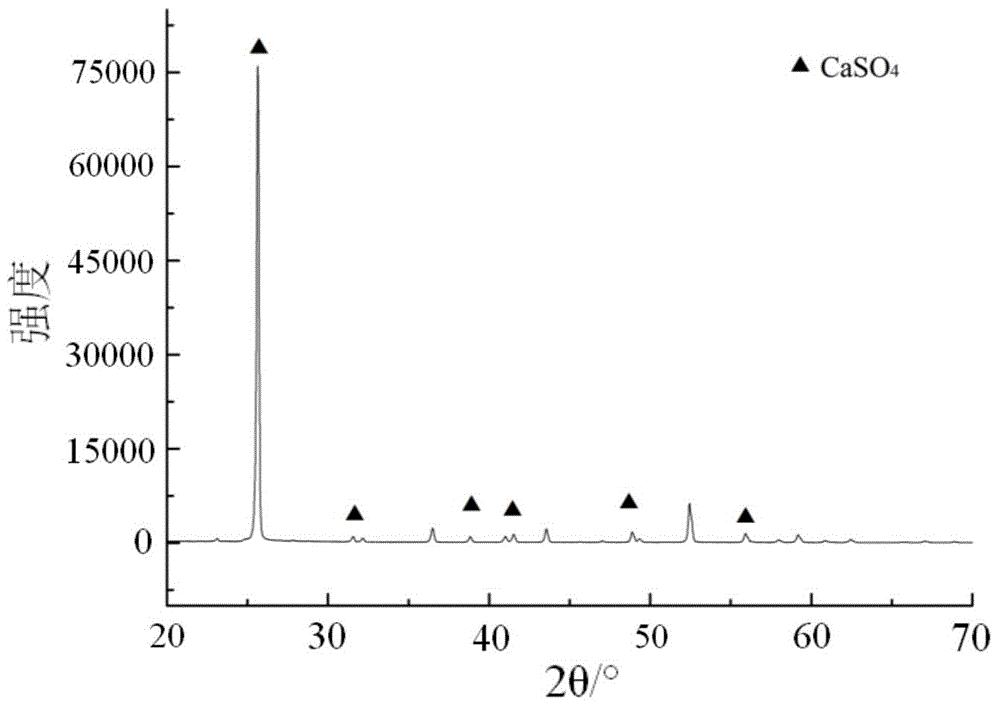

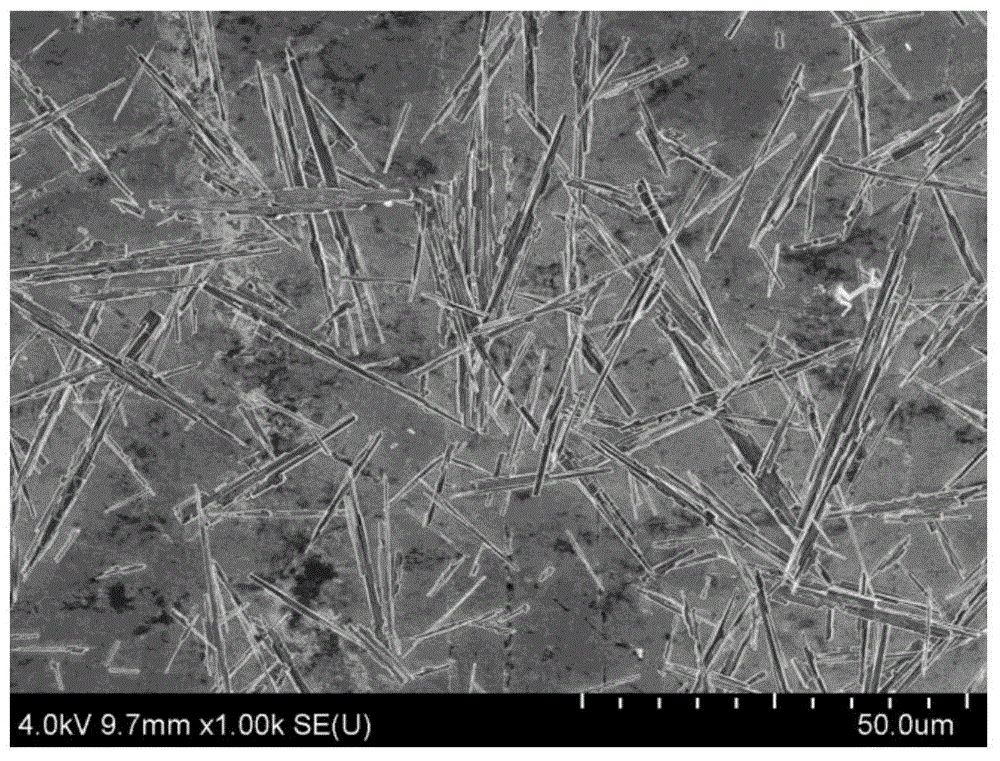

[0027] refer to figure 1 , the preparation method of the anhydrous calcium sulfate whisker according to the embodiment of the present invention comprises the steps:

[0028] In step 110, the raw gypsum is placed in water to form a first suspension. Wherein, the liquid-solid mass ratio of water to raw gypsum is 5.5-30:1.

[0029] In step 120, a crystal form control agent is added to the first suspension and stirred to form a white slurry.

[0030] Specifically, the molar ratio of crystal form control agent to raw gypsum is 0.7-5:1; wherein, the crystal form control agent can be selected from any one of calcium chloride, ammonium chloride, magnesium chloride, and ammonium sulfate.

[0031] In step 130, the white slurry is transferred to a hydrothermal reaction tank, and the white slurry is subjected to a hydrothermal reaction to obtain a second suspension.

[0032] Specifically, the setting temperature of the hydrothermal reaction kettle is 170°C-220°C, and the hydrothermal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com