Supported silver nanonet, and preparation method and application thereof

A technology of loaded silver and nano-network, which is applied in the field of nano-silver, can solve problems such as difficult handling and high energy consumption, and achieve rapid response, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

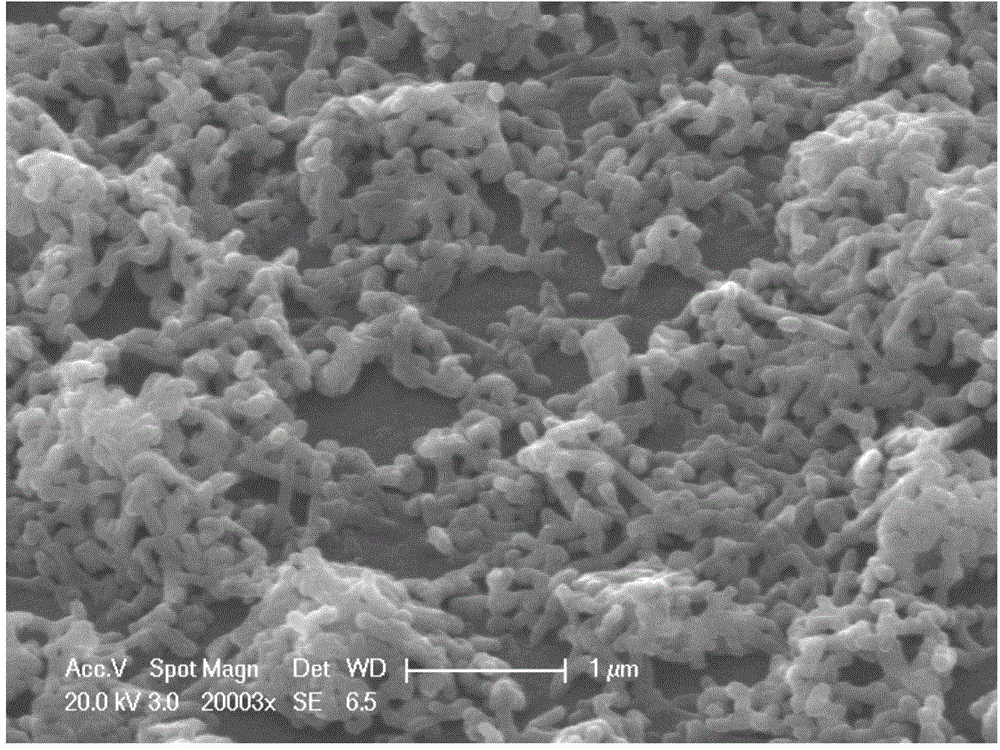

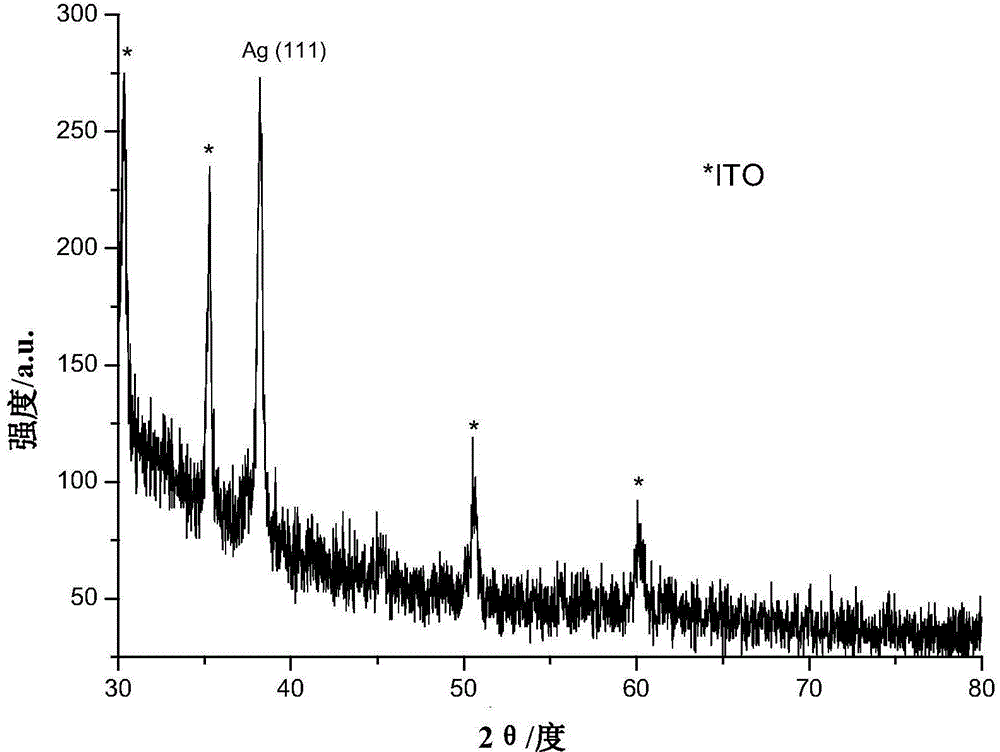

Image

Examples

Embodiment 1

[0027] (1) First cut the ITO into 0.8×1.5cm 2 , among which, the extra part is the contact area of the electrode clamp of the workstation, and the effective working area is about 0.8×1mm 2 , and then placed in acetone, ethanol, and deionized water for ultrasonic treatment for 5 minutes, and then exposed to air to dry naturally;

[0028] (2) Prepare 20 mL of copper sulfate solution containing n-propanol, wherein the mol ratio of n-propanol to copper sulfate is 100:1, and ITO is sandwiched in an electrochemical workstation as a working electrode, and its reference electrode and counter electrode are respectively Ag|AgCl, platinum sheet, and the front of ITO are aligned with the platinum sheet counter electrode with a distance of 2cm, and the reference electrode is in the middle, and put into the electrolytic cell. After adding the electrolyte, apply a voltage of -0.3V to the working electrode for 5 minutes. At this time, there is a layer of yellow substance on the ITO, which ...

Embodiment 2

[0031] (1) First cut the ITO into 0.8×1.5cm 2 , among which, the extra part is the contact area of the electrode clamp of the workstation, and the effective working area is about 0.8×1mm 2 , and then placed in acetone, ethanol, and deionized water for ultrasonic treatment for 5 minutes, and then exposed to air to dry naturally;

[0032] (2) Prepare 20 mL of copper sulfate solution containing n-propanol, wherein the mol ratio of n-propanol to copper sulfate is 150:1, and ITO is sandwiched in an electrochemical workstation as a working electrode, and its reference electrode and counter electrode are respectively Ag|AgCl, platinum sheet, and the front of ITO are aligned with the platinum sheet counter electrode with a distance of 2cm, and the reference electrode is in the middle, and put into the electrolytic cell. After adding the electrolyte, apply a voltage of -0.3V to the working electrode for 5 minutes. At this time, there is a layer of yellow substance on the ITO, which ...

Embodiment 3

[0035] (1) First cut the ITO into 0.8×1.5cm 2 , among which, the extra part is the contact area of the electrode clamp of the workstation, and the effective working area is about 0.8×1mm 2 , and then placed in acetone, ethanol, and deionized water for ultrasonic treatment for 15 minutes, and then exposed to air to dry naturally;

[0036](2) Prepare 20 mL of copper sulfate solution containing n-propanol, wherein the mol ratio of n-propanol to copper sulfate is 200:1, and ITO is sandwiched in an electrochemical workstation as a working electrode, and its reference electrode and counter electrode are respectively Ag|AgCl, platinum sheet, ITO face to the platinum sheet counter electrode, the distance is 2cm, the reference electrode is in the middle, and put into the electrolytic cell; after adding the electrolyte, apply a voltage of -0.2V to the working electrode for 5min , At this time, there is a layer of yellow substance on the ITO, which is cuprous oxide. Take out the ITO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com