An industrialized fully continuous PVD production process for zinc-magnesium alloy coated steel strip

A technology of alloy coating and production process, which is applied in the direction of metal material coating process, coating, sputtering coating, etc., can solve the problems of poor production continuity and poor product uniformity, and achieve excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] By adopting the process of the invention, zinc-magnesium alloy coated steel strips are produced with hot-dip galvanized GI coating base strips (skinned and oiled, not passivated). The base belt is DX56D+Z (cold-rolled IF steel), the plate thickness is 0.8mm, and the double-sided galvanizing is 100g / m 2 , (about 7μm), Table 1 is the chemical composition of IF steel.

[0067] Table 1IF steel chemical composition (%wt.)

[0068]

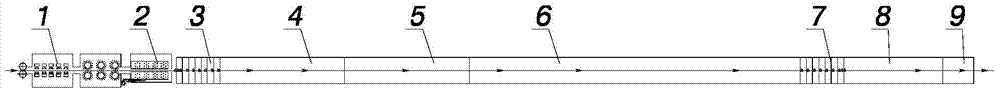

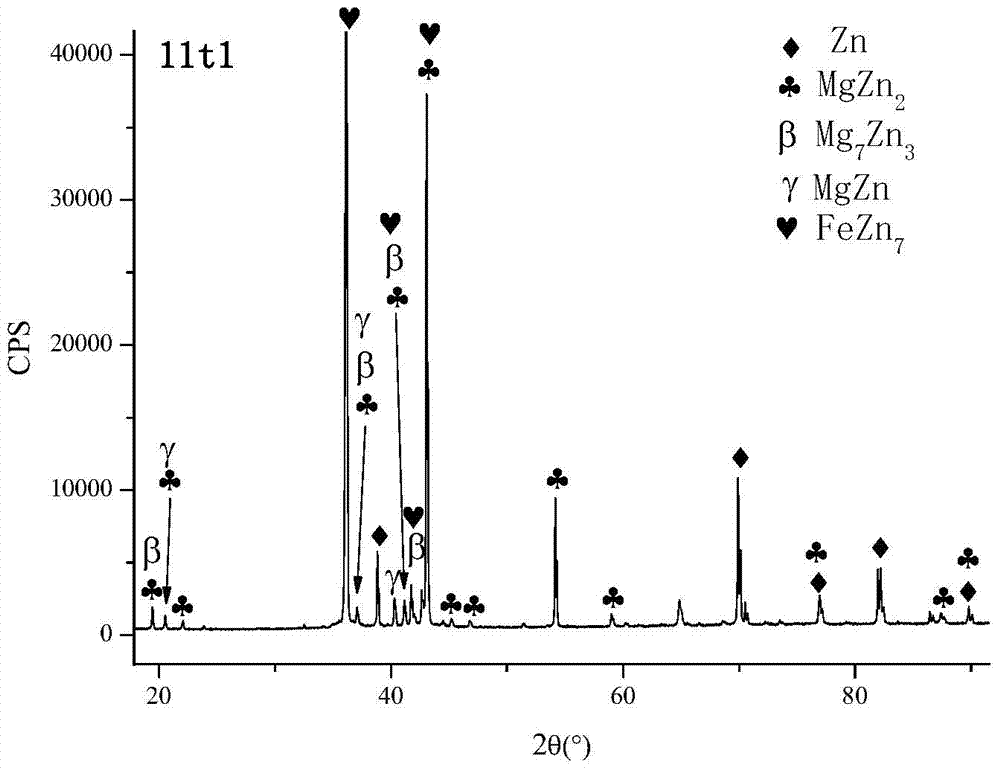

[0069] The process conditions of sputtering magnesium are: substrate temperature Ts=110°C, working pressure P=0.10Pa, target power density 3w / cm 2 , the GI substrate is biased at -200V with a duty cycle of 50%. The annealing process conditions are: 415°C-10s annealing, and the post-treatment is to apply a 5 μm thick TOC coating. figure 2 XRD image of zinc-magnesium alloy coating annealed at 415°C-10s (Ts=110°C).

[0070] From figure 2 It can be seen that after alloying, the alloy phase is mainly located on the surface, interface and zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com