A method for preparing al/ni reactive laminated foils by ebpvd

A technology of reactive lamination and lamination, which is applied in the field of preparation of Al/Ni reactive laminated foils, can solve the problems of easy introduction of impurities, unfavorable self-propagation rate, and low production efficiency at the interface of Al/Ni layers, and achieve no pollution at the interface , low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

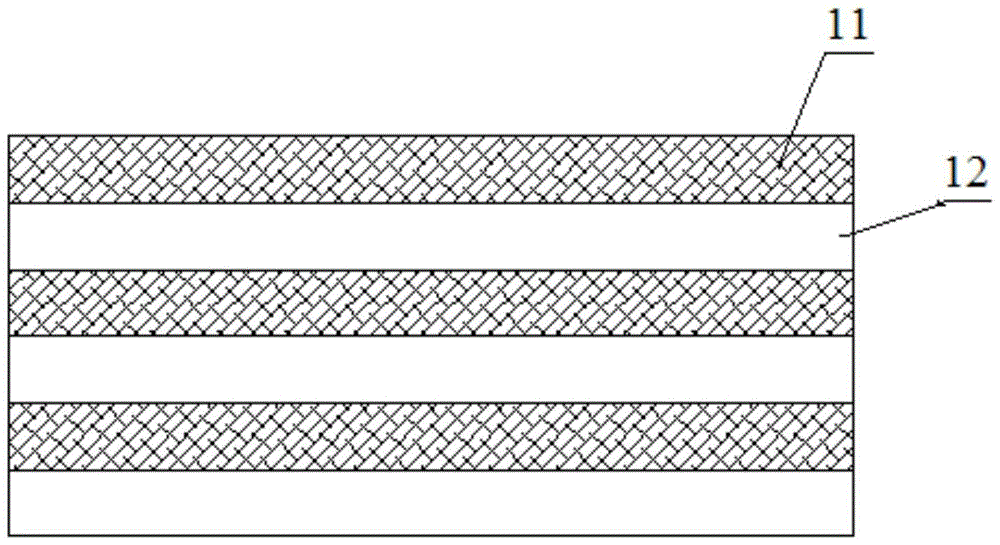

[0029] Embodiment 1: This embodiment is a method for preparing Al / Ni reaction laminated foil by EBPVD according to the following steps:

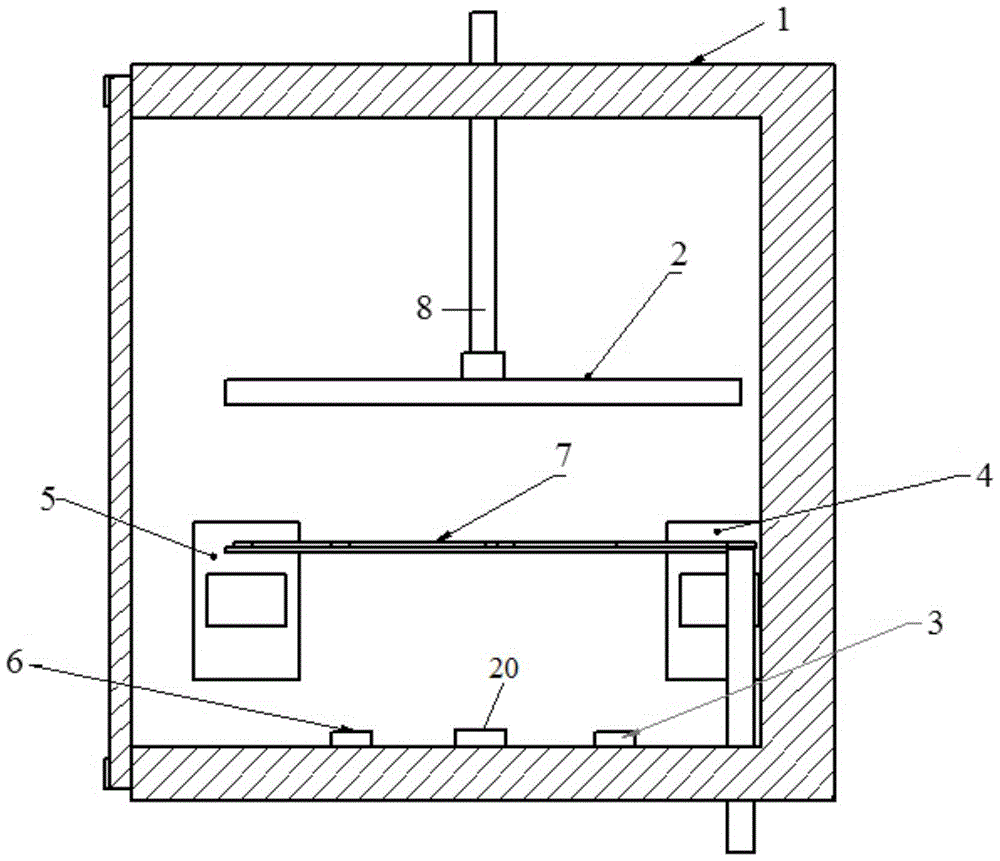

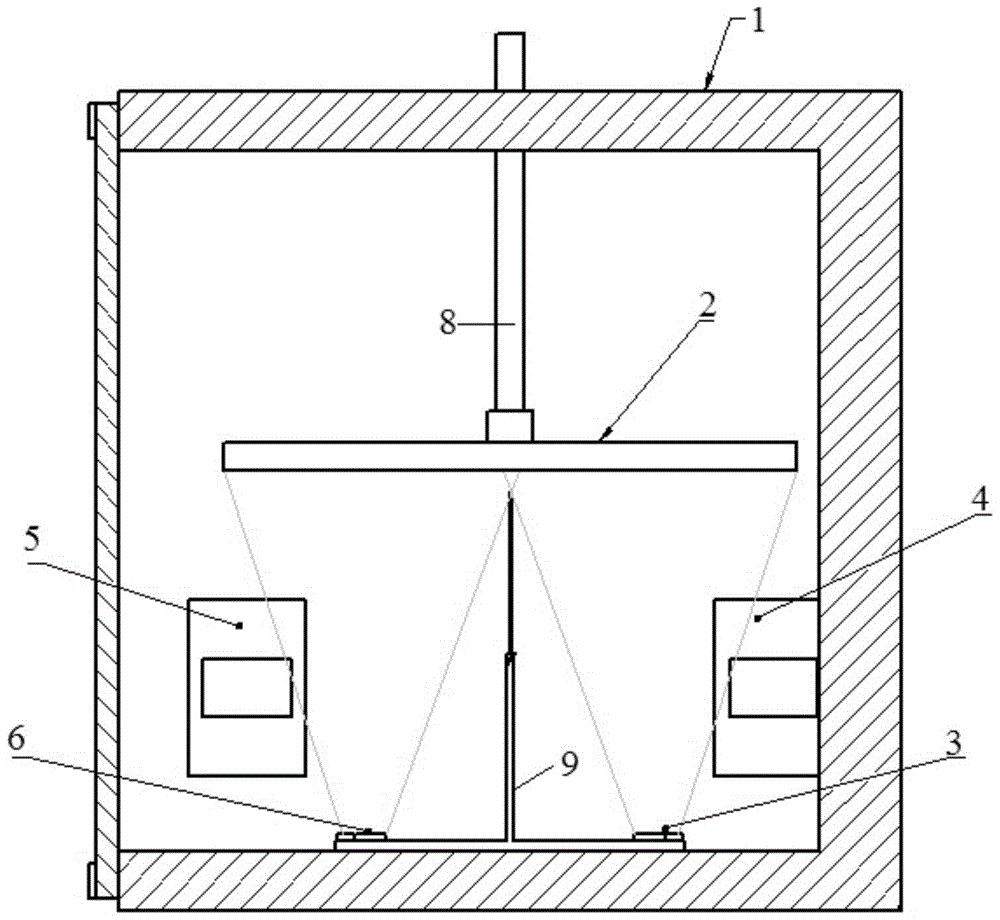

[0030] 1. Preliminary preparations for EBPVD: clean the ingots I and II, clean the vacuum chamber of the EBPVD equipment, and install the substrate. The ingot I is placed under the electron gun I, the cleaned ingot II is placed under the electron gun II, the separation layer material is placed between the ingot I and the ingot II, the substrate is wiped, and the baffle is closed; Ingot I is pure Al, and the ingot II is pure Ni;

[0031] 2. Preheating the ingot: close the vacuum chamber and evacuate until the vacuum degree is 6×10 -3At Pa, turn on the electron gun Ⅰ and electron gun Ⅱ, set the current of the electron gun Ⅰ to 0.02A~0.1A, and the current of the electron gun Ⅱ to 0.02A~0.1A, use the electron gun Ⅰ to scan the ingot Ⅰ for 5min~7min, and use the electron gun Ⅱ to scan the ingot Ⅰ Ingot II was scanned for 5min-7min, then the cur...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the material of the separation layer in step 1 is sodium chloride or calcium chloride. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the substrate described in Step 1 is a large heat sink integral substrate, a circulating water-cooled substrate, a static water-cooled substrate, a segmented substrate, The base plate of the radiation tube or the base plate of the water cooling box, and the thickness of the base plate is greater than 40mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com