Coal direct liquefaction circulating hydrogen supply solvent and its preparation method

A technology of direct coal liquefaction and coal direct liquefaction of oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, can solve the problem of poor hydrogen supply capacity of circulating hydrogen supply solvent, and improve the conversion rate of coal and oil The effect of improving the yield, improving the hydrogen supply capacity, and improving the dissolution and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

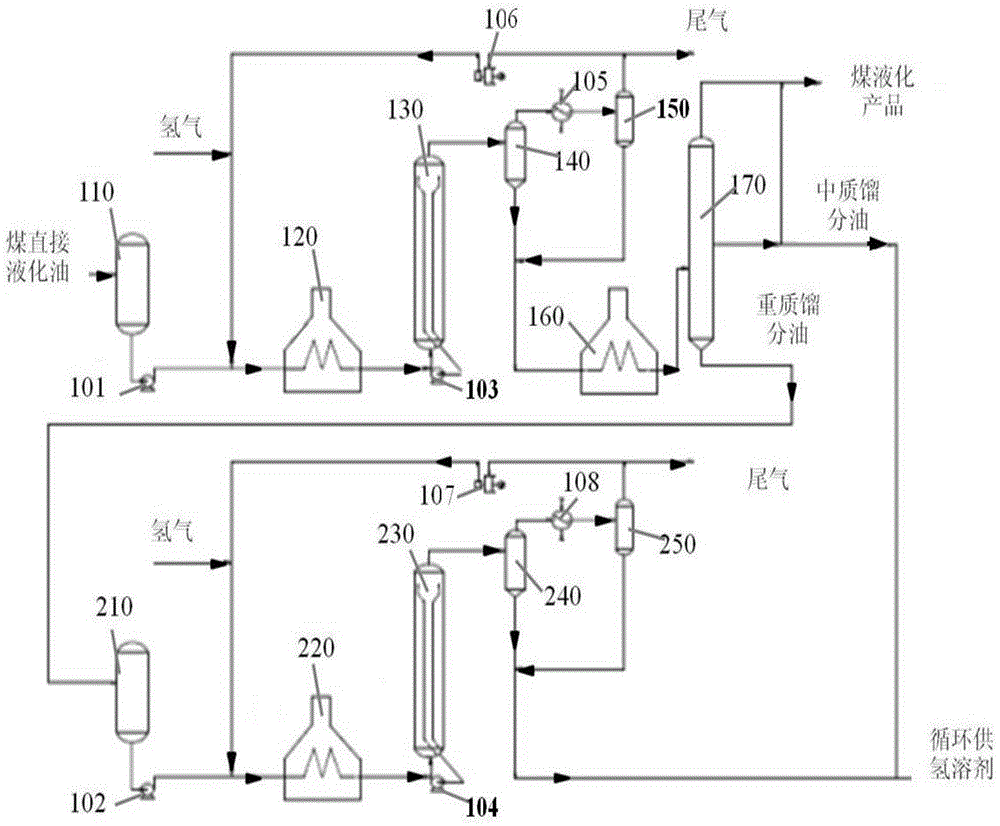

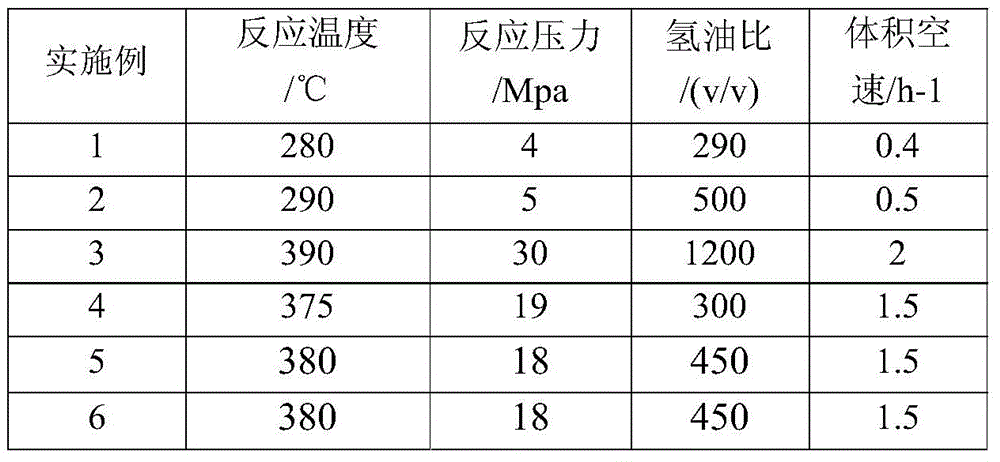

[0024] As described in the background technology section, the polycyclic aromatic hydrocarbons in the recycled hydrogen-donating solvent produced by the existing process are not fully partially saturated, which leads to poor hydrogen-donating capacity of the recycled hydrogen-donating solvent, which in turn affects coal Conversion and oil yield during direct liquefaction. In order to solve this problem, the present invention provides a method for preparing a circulating hydrogen-supplying solvent for direct coal liquefaction, which includes the following steps: S1, performing the first catalytic hydrogenation of direct coal liquefaction oil to obtain the first gas phase product and the second One liquid phase product; S2, fractionate the first liquid phase product to obtain light distillate oil, middle distillate oil and heavy distillate oil; S3, carry out the second catalytic hydrogenation of part or all of the heavy distillate oil process, to obtain the second liquid phase p...

Embodiment 1

[0039] Such as figure 1 As shown, the direct coal liquefaction whole distillate oil is passed into the first buffer tank 110, after being boosted by the first high-pressure raw material pump 101, it is mixed with hydrogen, and then enters the first raw material heating furnace 120, and is heated to raise the temperature. The first raw material heating furnace 120 The outlet temperature is 250°C; the heated oil-gas mixture enters the first hydrogenation reactor 130 (fixed-bed reactor), and the bottom of the first hydrogenation reactor 130 is equipped with a first forced circulation pump 103. In the first hydrogenation reactor 130 Catalytic hydrogenation reactions, including partial saturation of aromatics and removal of heteroatoms, etc.

[0040] The material at the outlet of the first hydrogenation reactor 130 (fixed bed reactor) enters the first hot high-pressure separator 140 after being cooled by heat exchange, and the temperature of the first hot high-pressure separator 14...

Embodiment 2

[0045] Such as figure 1 As shown, the coal direct liquid whole distillate oil is passed into the first buffer tank 110 as a raw material, after being boosted by the first high-pressure raw material pump 101, it is mixed with hydrogen gas, and then enters the first raw material heating furnace 120, and is heated to raise the temperature. The outlet temperature of the furnace 120 is 250°C; the heated oil-gas mixture enters the first hydrogenation reactor 130 (fixed bed reactor), and the bottom of the first hydrogenation reactor 130 is equipped with a first forced circulation pump 103. Catalytic hydrogenation reaction is carried out in the device 130, which includes partial saturation of aromatic hydrocarbons and removal of heteroatoms.

[0046] The material at the outlet of the first hydrogenation reactor 130 (fixed bed reactor) enters the first hot high-pressure separator 140 after being cooled by heat exchange, and the temperature of the first hot high-pressure separator 140 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com