Improver for sandy soil

A soil conditioner and soil technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of no water retention function, poor improvement effect, and inability to improve soil properties, and achieve the effect of improving soil structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

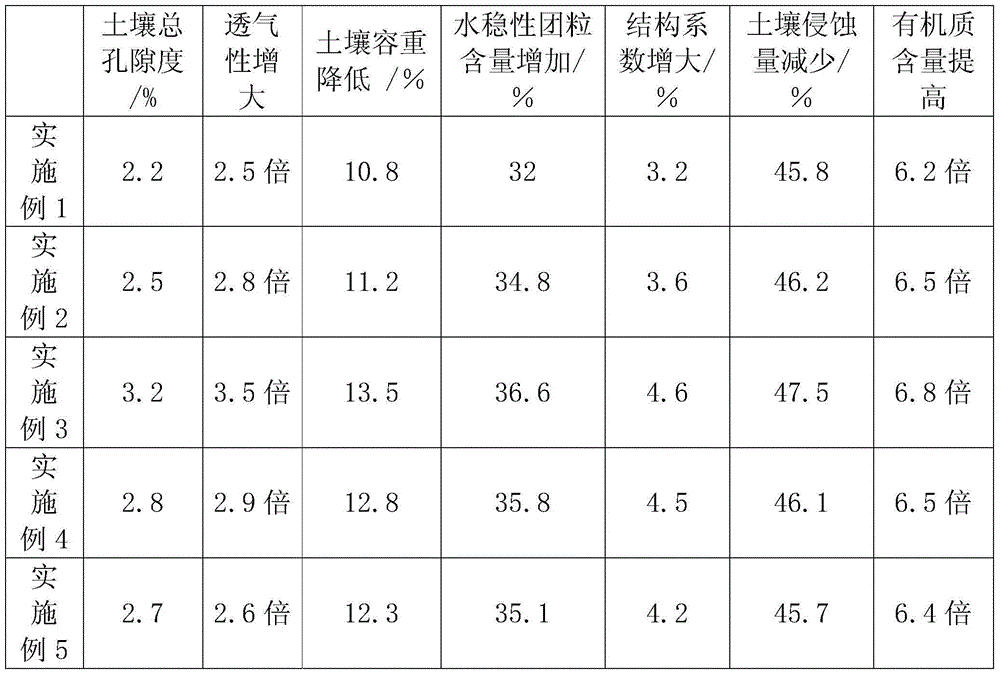

Embodiment 1

[0023] An improving agent for sandy soil, the composition of the improving agent for sandy soil is as follows: 50 parts of organic fermented product, 12 parts of peat humic acid, 10 parts of sucrose residue, 0.06 part of pH buffering agent, 0.18 part of soil disinfectant , 5 parts of diatomaceous earth, 0.2 parts of water retaining agent.

[0024] Wherein, the organic fermented product is rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum residue, green corn stalks, and lotus leaf through natural stacking fermentation, wherein rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum The mass ratio of dregs, green corn stalks and lotus leaves is 10:8:1:1.1:20:6.

[0025] Wherein, the peat humic acid is extracted by the following process:

[0026] (1) Alkali dissolution: add sodium phosphate alkali solution to peat, the solid-to-liquid ratio is 1:0.1, stir for 10 hours, grind in a ball mill, grind through a 200-mesh sieve, heat to 60-80°C in a water bath, and ...

Embodiment 2

[0033] An improving agent for sandy soil, the composition of the improving agent for sandy soil is as follows: 60 parts of organic fermented product, 13 parts of peat humic acid, 12 parts of sucrose residue, 0.088 parts of pH buffering agent, and 0.2 part of soil disinfectant , 6 parts of diatomaceous earth, 0.5 part of water retaining agent.

[0034] Wherein, the organic fermented product is rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum residue, green corn stalks, and lotus leaf through natural stacking fermentation, wherein rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum The mass ratio of dregs, green corn stalks and lotus leaves is 10:8:1:1.1:20:6.

[0035] Wherein, the peat humic acid is extracted by the following process:

[0036] (1) Alkali dissolution: add sodium phosphate alkali solution to peat, the solid-to-liquid ratio is 1:0.2, stir for 8 hours, grind in a ball mill, grind through a 300-mesh sieve, heat in a water bath to 60-80°C an...

Embodiment 3

[0043] An improving agent for sandy soil, the composition of the improving agent for sandy soil is as follows: 65 parts of organic fermented product, 15 parts of peat humic acid, 14 parts of sucrose residue, 0.12 part of pH buffering agent, 0.3 part of soil disinfectant , 6.5 parts of diatomaceous earth, and 0.8 parts of water retaining agent.

[0044] Wherein, the organic fermented product is rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum residue, green corn stalks, and lotus leaf through natural stacking fermentation, wherein rapeseed meal, wheat bran, mushroom residue, Ganoderma lucidum The mass ratio of dregs, green corn stalks and lotus leaves is 10:8:1:1.1:20:6.

[0045] Further, the peat humic acid is extracted using the following process:

[0046] (1) Alkali dissolution: add sodium phosphate alkali solution to peat, the solid-to-liquid ratio is 1:0.3, stir for 8 hours, grind in a ball mill, grind through a 500-mesh sieve, heat to 60-80°C in a water bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com