UV curing adhesive, quantum dot light conversion film and white light emitting device comprising quantum dot light conversion film

A light conversion film and adhesive technology, which is applied in the direction of non-polymer organic compound adhesives, film/sheet adhesives, adhesives, etc., can solve problems such as easy to fade, quantum dot light conversion film failure, etc. , to achieve the effect of improving stability, high compactness, improving service life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The composition of the UV curing adhesive includes 3.0 g of low-polarity oligomers with the structure of formula (I), wherein the R of the above-mentioned oligomers 1 is a silicon atom, R 2 is a carbon atom, R 3 for SiH 3 , degree of polymerization p=7; 1.0g of acrylate monomer with formula (Ⅲ) structure, wherein, R of the above-mentioned oligomer 4 Be phenyl, degree of polymerization n=8; 1.2g of acrylate monomer of cycloalkane with structure of formula (IV), 0.5g of dipentaerythritol hexaacrylate, 0.2g of photoinitiated monomer with structure of formula (Ⅴ) agent.

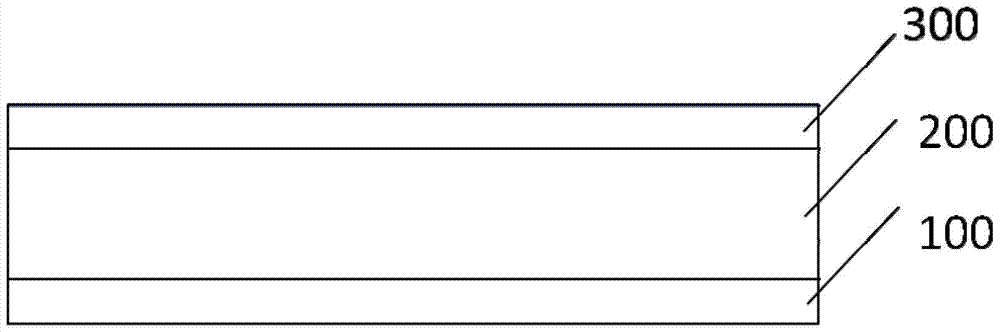

[0065] According to the weight ratio of red quantum dots, green quantum dots and UV curing adhesive is 1.5:6.0:100, red and green quantum dots are added to the UV curing adhesive of the above formula and stirred to obtain a mixture; then the above mixture is coated Spread on the transparent support layer 600, the thickness of the mixture is 100 μm, and then completely cured by light to obtain a quantum...

Embodiment 2

[0068] The composition of the UV curing adhesive includes 3.0 g of low-polarity oligomers with the structure of formula (I), wherein the R of the above-mentioned oligomers 1 is a silicon atom, R 2 is a carbon atom, R 3 for SiH 3 , degree of polymerization p=7; 1.0g of acrylate monomer with formula (Ⅲ) structure, wherein, R of the above-mentioned oligomer 4 Be phenyl, degree of polymerization n=8; 1.2g of acrylate monomer of cycloalkane with structure of formula (IV), 0.5g of dipentaerythritol hexaacrylate, 0.2g of photoinitiated monomer with structure of formula (Ⅴ) agent.

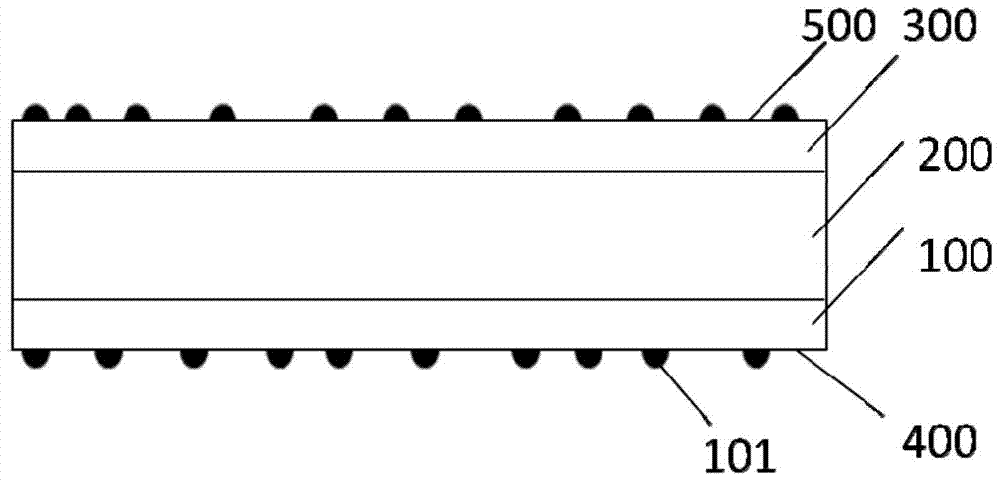

[0069] The first barrier layer 100 was prepared by coating a 50 μm thick UV-curable adhesive with a low-polarity formulation without quantum dots on the transparent support layer 600 and cured completely. The structure of the transparent support layer 600 is porous. According to the weight ratio of red quantum dots, green quantum dots and UV curing adhesive is 1.5:6.0:100, red and green quantum dots ar...

Embodiment 3

[0072] The composition of the UV curing adhesive includes 3.0 g of low-polarity oligomers with the structure of formula (I), wherein the R of the above-mentioned oligomers 1 is a silicon atom, R 2 is a carbon atom, R 3 for SiH 3 , degree of polymerization p=7; 1.0g of acrylate monomer with formula (Ⅲ) structure, wherein, R of the above-mentioned oligomer 4 Be phenyl, degree of polymerization n=8; 1.2g of acrylate monomer of cycloalkane with structure of formula (IV), 0.5g of dipentaerythritol hexaacrylate, 0.2g of photoinitiated monomer with structure of formula (Ⅴ) agent.

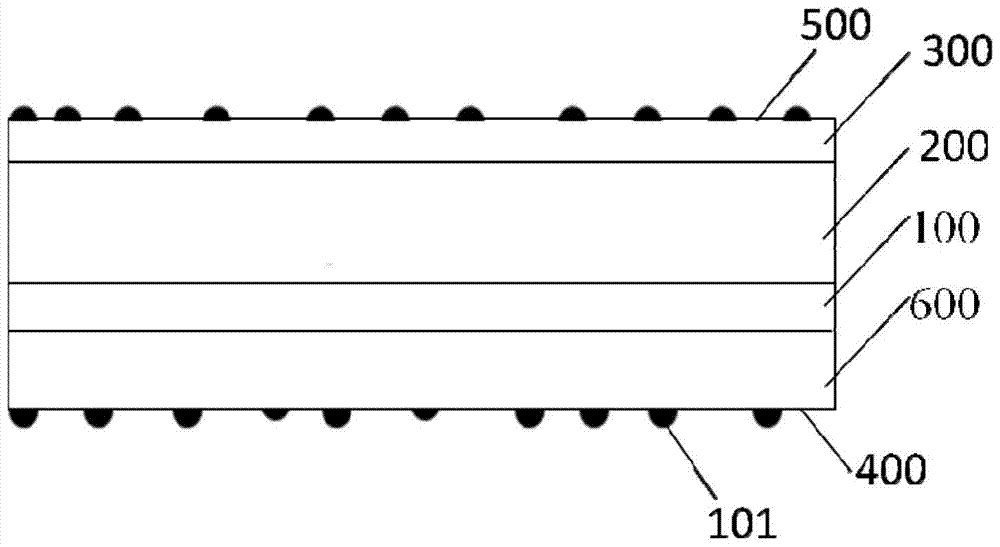

[0073] The first barrier layer 100 was prepared by coating a 50 μm thick UV-curable adhesive with a low-polarity formula without quantum dots on the transparent support layer 600 and cured completely. The structure of the transparent support layer 600 is surface atomization. According to the weight ratio of red quantum dots, green quantum dots and UV curing adhesive is 1.5:6.0:100.0, add red and green ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com