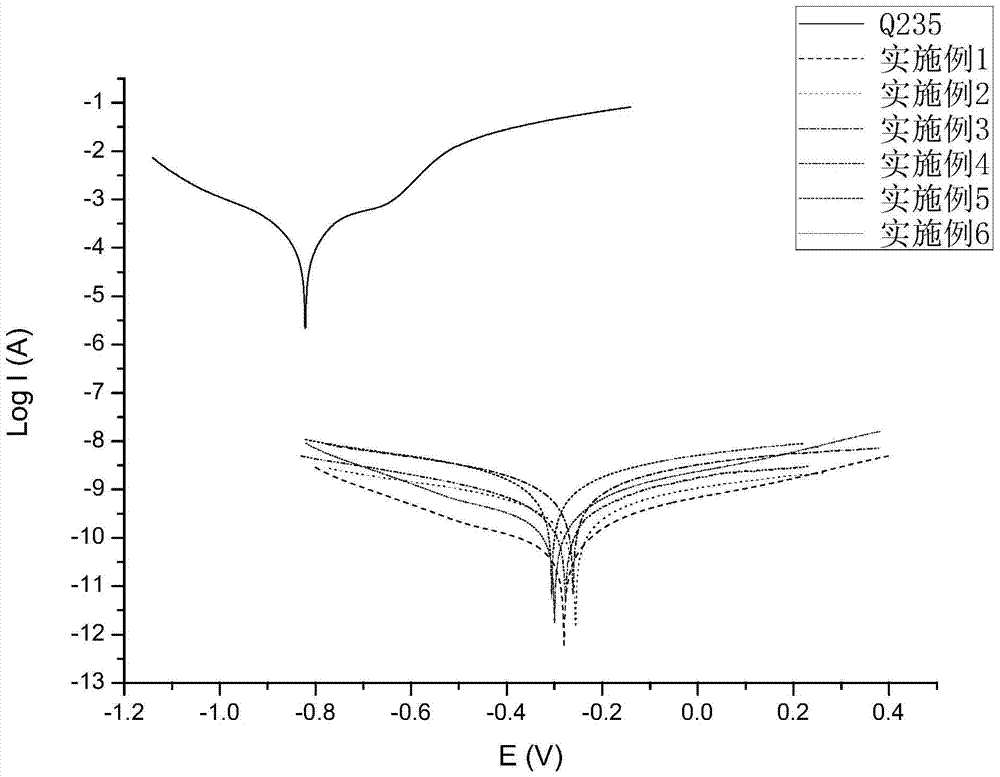

A kind of polyaniline graphene nanocomposite anticorrosion coating and preparation method thereof

A nano-composite, anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as easy agglomeration properties, and achieve the effects of inhibiting electrochemical corrosion, improving compatibility, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

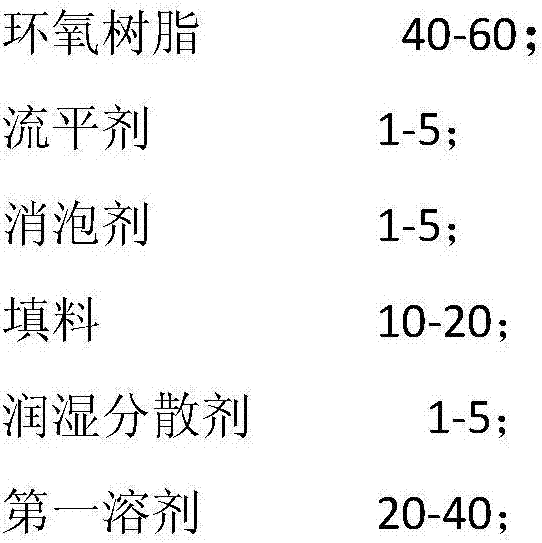

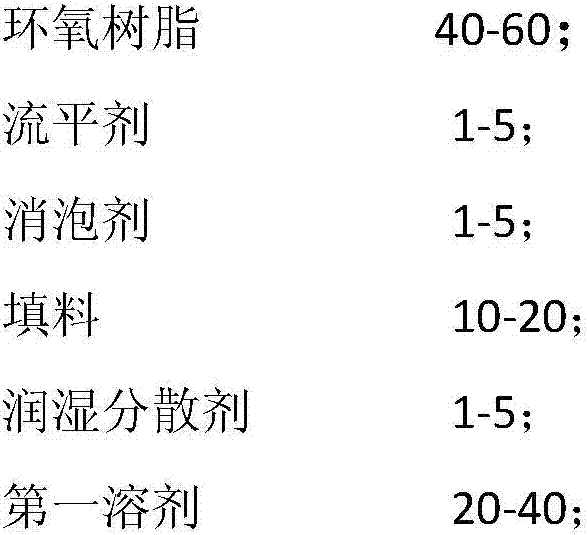

[0048] In terms of parts by mass, the raw material formula of component A consists of:

[0049]

[0050] In terms of parts by mass, the raw material formula of component B consists of:

[0051] Polyamide curing agent 48;

[0052] Intrinsic state polyaniline graphene composite material 10;

[0053] Xylene 42.

[0054] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0055] (1) Preparation of intrinsic polyaniline graphene composites

[0056] 1) Add graphene to the hydrochloric acid solution, ultrasonically crush the cells for 10 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at a speed of 200 rpm at 0‐5 °C. Wherein, the concentration of aniline is 0.05 mol / L, the concentration of graphene is 0.5 mg / mL, and the concentration of hydrochloric acid is 0.1 mol / L. Dissolve the oxidant into a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphen...

Embodiment 2

[0063] In terms of parts by mass, the raw material formula of component A consists of:

[0064]

[0065] In terms of parts by mass, the raw material formula of component B consists of:

[0066]

[0067] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0068] (1) Preparation of intrinsic polyaniline graphene composites

[0069]1) Add graphene into the hydrochloric acid solution, ultrasonically crush the cells for 30 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at 0-5°C at a speed of 200rpm. Wherein, the concentration of aniline is 0.09 mol / L, the concentration of graphene is 0.8 mg / mL, and the concentration of hydrochloric acid is 0.3 mol / L. Dissolve the oxidizing agent in a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphene, stir and mix evenly at a speed of 200rpm at 0-5°C, react for 18 hours, centrifuge and wash three times to ob...

Embodiment 3

[0076] In terms of parts by mass, the raw material formula of component A consists of:

[0077]

[0078] In terms of parts by mass, the raw material formula of component B consists of:

[0079]

[0080] Prepare polyaniline graphene nanocomposite anticorrosion coating as follows:

[0081] (1) Preparation of intrinsic polyaniline graphene composites

[0082] 1) Add the graphene into the hydrochloric acid solution, ultrasonically crush the cells for 45 minutes, add aniline after the dispersion is uniform, and stir and mix evenly at a speed of 200 rpm at 0‐5 °C. Wherein, the concentration of aniline is 0.19 mol / L, the concentration of graphene is 2 mg / mL, and the concentration of hydrochloric acid is 0.5 mol / L. Dissolve the oxidizing agent in a certain concentration of hydrochloric acid solution, add it into the hydrochloric acid solution containing aniline and graphene, stir and mix evenly at 0-5°C at a speed of 200rpm, react for 12 hours, centrifuge and wash three times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com