A kind of high voltage direct current cable material and preparation method thereof

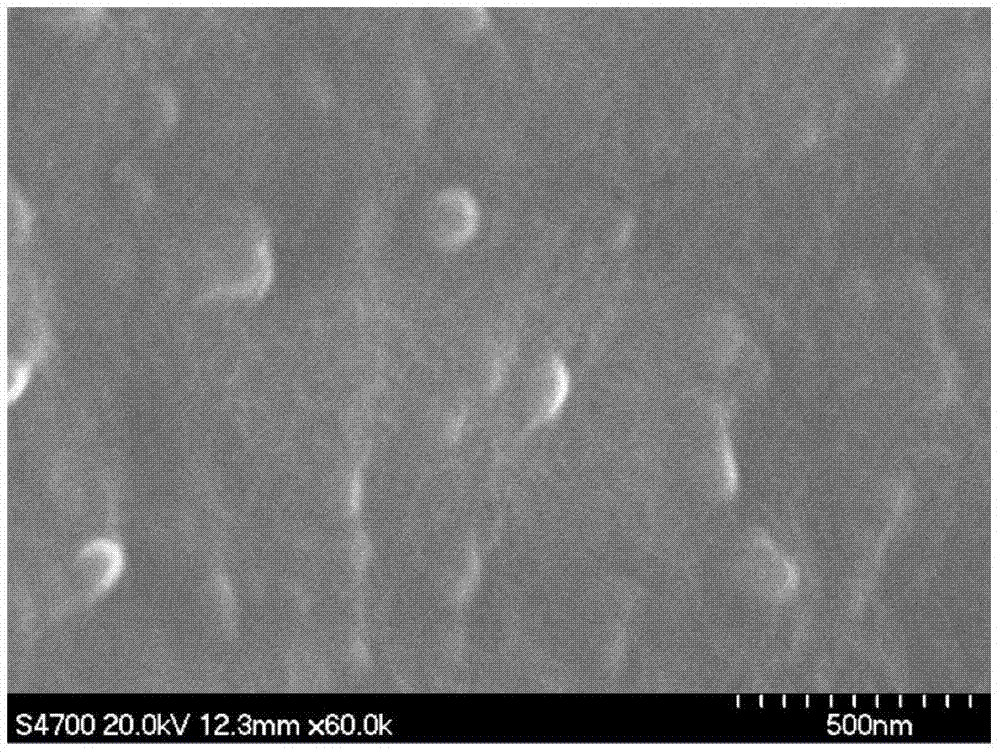

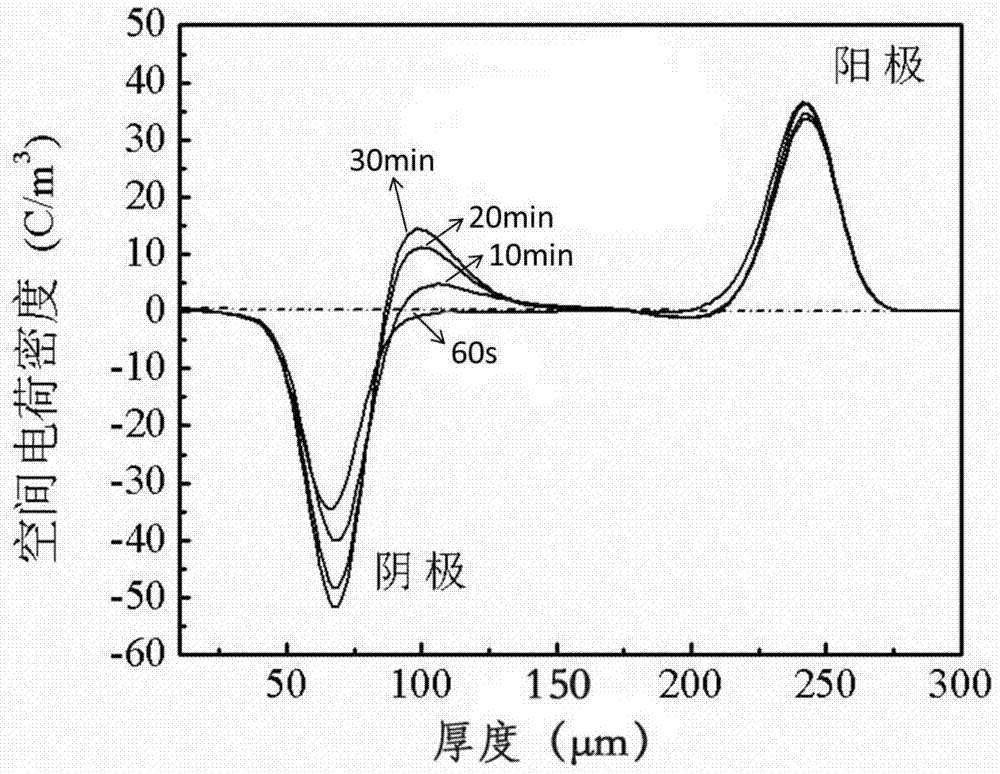

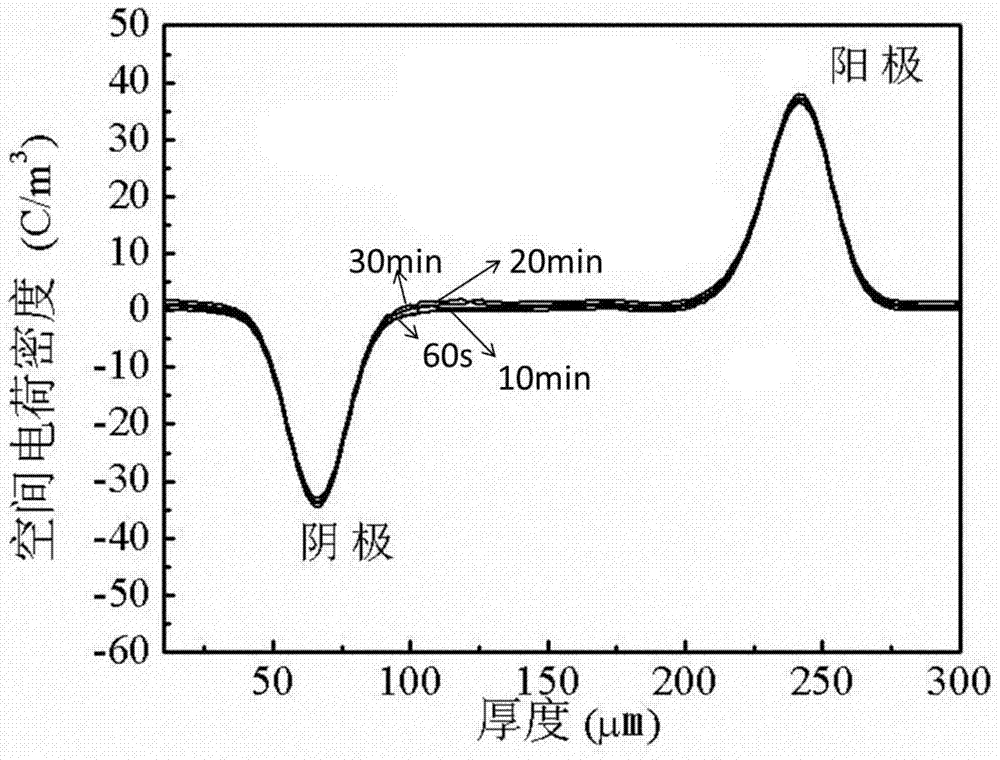

A high-voltage DC, cable material technology, used in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as injection accumulation, and achieve the effect of suppressing electrical tree branches, high breakdown strength, and excellent space charge accumulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Cable material formula

[0031]

[0032] (2) The preparation process is

[0033] 1) Preparation of modified nano-magnesium oxide: mix magnesium oxide with a particle size of 30nm and coupling agent KH550 at a mass ratio of 20:3, mill on a roller mill for 1 hour, and set aside;

[0034] 2) Premixing: mix low-density polyethylene and liquid paraffin evenly in a high-speed mixer, raise the temperature of the material to 60°C, then add the modified nano-magnesia in step 1), keep the temperature of the material until it is evenly mixed, and finally add anti Oxygen 300 and dibenzoyl are mixed evenly again;

[0035] 3) Pelletizing: the mixed material is prepared in an extruder at a temperature of 200° C. at a discharge speed of 300 r / min to prepare a cable material.

Embodiment 2

[0037] (1) The formula of the cable material is as follows:

[0038]

[0039] (2) The preparation process is:

[0040] 1) Preparation of modified nano-magnesia: mix magnesium oxide with a particle size of 50nm and coupling agent KH580 at a mass ratio of 20:3, mill on a roller mill for 1.5h, and set aside;

[0041] 2) Premixing: mix low-density polyethylene and liquid paraffin evenly in a high-speed mixer, add the modified nano-magnesium oxide prepared in step 1) after the temperature of the material rises to 65°C, keep the temperature of the material until it is evenly mixed, and finally add anti Oxygen 300 and 2,2-methyl-benzoyl are mixed evenly again;

[0042] 3) Extrusion granulation: the mixed material is prepared in an extruder at a temperature of 220° C. at a discharge speed of 350 r / min to prepare a cable material.

Embodiment 3

[0044] (1) Cable material formula

[0045]

[0046] (2) Preparation process

[0047] 1) Preparation of modified nano-magnesium oxide: mix magnesium oxide with a particle size of 80nm and coupling agent KH560 at a mass ratio of 20:3, mill on a roller mill for 2 hours, and set aside;

[0048] 2) Premixing: mix low-density polyethylene and liquid paraffin evenly in a high-speed mixer, raise the temperature of the material to 70°C, then add the modified nano-magnesia prepared in step 1), keep the temperature of the material until it is evenly mixed, and finally add anti Oxygen 300 and 2,2-ethyl-benzoyl were mixed evenly again;

[0049] 3) Extrusion granulation: the mixed material is prepared in an extruder at a temperature of 250° C. at a discharge speed of 400 r / min to prepare a cable material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com