Phosphorus-nitrogen cooperative flame-retardant epoxy polymer and preparation method thereof

A technology of epoxy polymer and synergistic flame retardant, which is applied in the field of polymer flame retardant, can solve the problems of small migration, lack of effect of chemical bonds and resin matrix connection, etc., and achieve small impact on mechanical properties, high conversion rate, and reaction The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

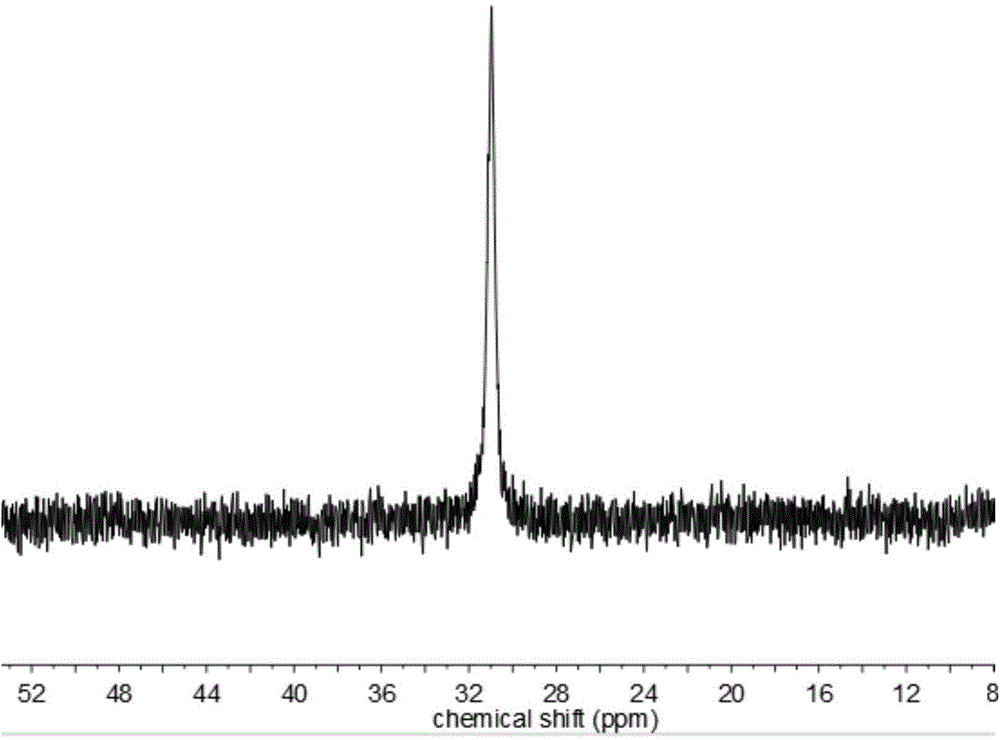

Image

Examples

Embodiment 1

[0036] Step 1, the synthesis of the first polymerized monomer (MAdiDOPO) described:

[0037] First, 43.2g (0.2mol) of DOPO, 10.9g (0.1mol) of p-aminophenol, 6.0g (0.1mol) of paraformaldehyde and 200mL of ethanol were added to a 500mL three-necked flask, and the reaction was stirred at 50°C for 5h , the product was washed with methanol to obtain a phenolic intermediate compound. Then, 33.2g (0.05mol) of the prepared phenolic intermediate 10.1g (0.10mol) of triethylamine and 100mL of dichloromethane were placed at 0°C and slowly dripped into 10.5g (0.10mol) Methacryloyl chloride, after the dropwise addition, continue to stir and react for 8 hours, filter to remove triethylamine hydrochloride, and purify the crude product by washing, rotary evaporation and drying to obtain the phosphorus nitrogen flame retardant MAdiDOPO containing active double bonds (References: CN104262398A).

[0038] Step 2, the synthesis of the second polymerized monomer (UPyMA) described:

[0039] Comple...

Embodiment 2~8

[0043] Experimental steps 1 and 2 are the same as in Example 1. The preparation method of step 3 is similar to that of Example 1, except that the ratio of different monomers is adjusted by adjusting the value of x:y:z, so that the ratio of phosphorus to nitrogen in the polymer is changed. The specific feeding ratio of UPyMA, GMA, and MAdiDOPO is shown in Table 1:

[0044] Table 1

[0045]

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

UPyMA

20

30

40

50

60

70

0

GMA

30

30

30

30

30

30

30

MAdiDOPO

50

40

30

20

10

0

70

[0046] Those of ordinary skill in the art will know that when the technical parameters of the present invention vary within the following ranges, it can be expected to obtain the same or similar technical effects as those of the above-described embodiments:

[0047] A phosphorus-nitrogen syner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com