A kind of eco-friendly wheat straw matrix compound fertilizer and preparation method thereof

A wheat straw-friendly technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as imbalance of nutrient elements, high cost of fermentation strains, long fermentation time, etc., to delay fermentation speed, reduce heavy metal content, The effect of improving the soil environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

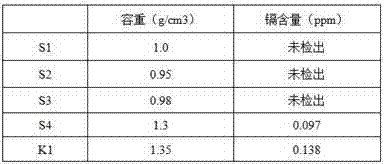

Examples

Embodiment 1

[0024] An eco-friendly wheat straw matrix compound fertilizer, the preparation method of which is:

[0025] (1) Preparation of base material: crush wheat straw into 1-3 cm, then put it into an aqueous solution containing 15% triethanolamine and 8% fatty acid methyl ester ethoxylate accounting for 8 times the weight of wheat straw and soak it for 8 hours, remove it, To obtain the pretreated wheat straw, stir the livestock and poultry manure and the pretreated wheat straw evenly according to the dry weight ratio of 3:7, pour the aqueous solution soaked in the wheat straw so that the water content is 65%, and obtain the base material;

[0026] (2) Composting: first spread a layer of 20cm thick sawdust, light it, and immediately cover the livestock and poultry manure evenly on the sawdust after the sawdust is burned out. 1.5 meters;

[0027] (3) Manure dumping: after 10 days, the first manure dumping is performed, and then every 6-8 days (when the temperature is higher than 65°C)...

Embodiment 2

[0030] An eco-friendly wheat straw matrix compound fertilizer, the preparation method of which is:

[0031] (1) Preparation of base material: crush wheat straw into 1-3 cm, then put it into an aqueous solution containing 17.8% triethanolamine and 6% fatty acid methyl ester ethoxylate which accounts for 10 times the weight of wheat straw and soak it for 7 hours, remove it, To obtain the pretreated wheat straw, stir the livestock and poultry manure and the pretreated wheat straw evenly according to the dry weight ratio of 3:7, pour the aqueous solution soaked in the wheat straw so that the water content is 60%, and obtain the base material;

[0032] (2) Composting: first spread a layer of 20cm thick sawdust, light it, and immediately cover the livestock and poultry manure evenly on the sawdust after the sawdust is burned out. is 2 meters;

[0033] (3) Manure dumping: after 10 days, the first manure dumping is performed, and then every 6-8 days (when the temperature is higher th...

Embodiment 3

[0036] An eco-friendly wheat straw matrix compound fertilizer, the preparation method of which is:

[0037] (1) Base material preparation: Crush wheat straw into 1-3 cm, then soak it in an aqueous solution containing 20% triethanolamine and 5% fatty acid methyl ester ethoxylate, accounting for 9 times the weight of wheat straw, for 6 hours, and remove it. To obtain the pretreated wheat straw, stir the livestock and poultry manure and the pretreated wheat straw evenly according to the dry weight ratio of 3:7, pour the aqueous solution soaked in the wheat straw so that the water content is 55%, and obtain the base material;

[0038] (2) Composting: first spread a layer of 20cm thick sawdust, light it, and immediately cover the livestock and poultry manure evenly on the sawdust after the sawdust is burned out. is 2.5 meters;

[0039] (3) Manure dumping: the first time after 10 days, then every 6-8 days (when the temperature is higher than 65°C), the manure is dumped once, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com