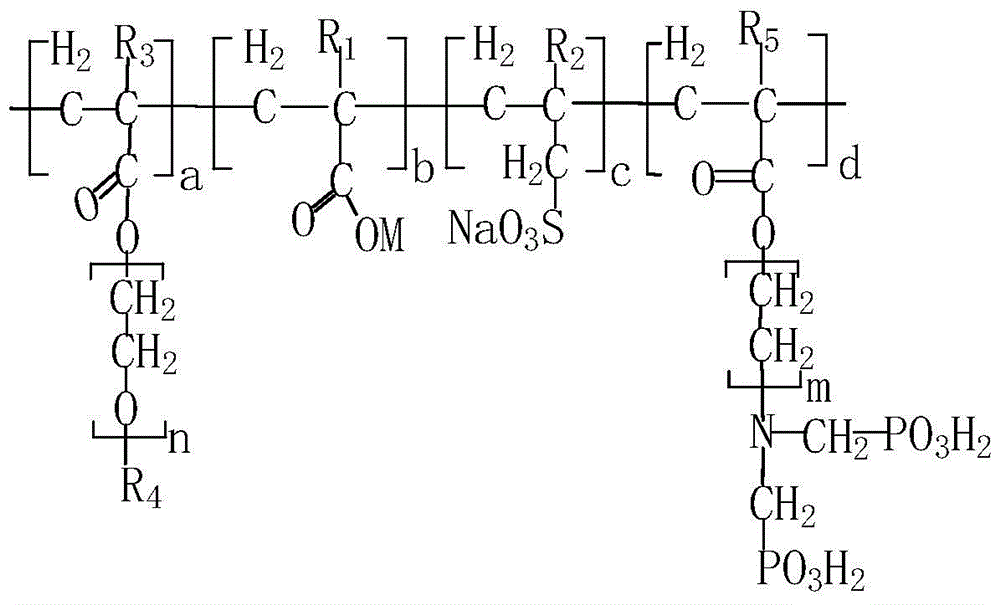

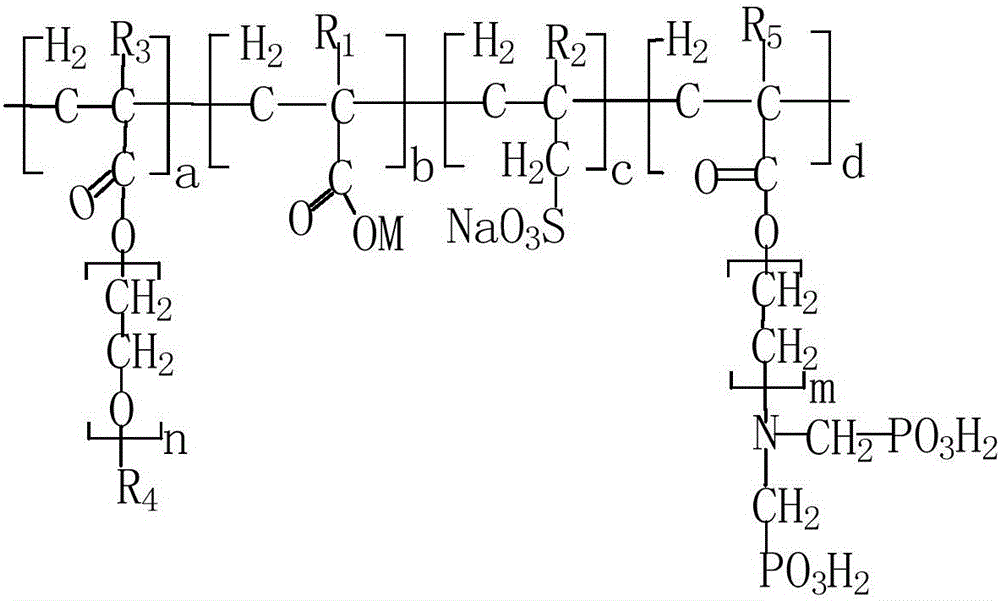

Polycarboxylate water-reducing agent, its preparation method, water-reducing composition and concrete

A technology of water reducer and polycarboxylate, which is applied in the field of new polycarboxylate water reducer for high-performance pipe piles and its preparation, can solve the problems of weakening plasticizing effect, settlement, and precipitation, so as to facilitate production operation, The effect of reducing production costs and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 21

[0032] The preparation method of novel polycarboxylate water reducer, the steps are as follows:

[0033] Step 1: Prepare or purchase the macromer, and weigh the raw materials according to the predetermined ratio;

[0034] Step 2: Add alkyl polyether, acrylic acid monomer, polymerization inhibitor, catalyst and water coordinating agent into the reaction kettle and raise the temperature to 100°C, carry out esterification reaction in reflux state for 4 hours, and obtain the intermediate product; the stirring speed is 1600r / min;

[0035] Step 3: Separate the intermediate product and heat it to 80°C for dissolution, and add other monomers and initiator solutions dropwise at the same time. The dropping time is 1 hour. After the dropwise addition, keep warm for 6 hours. After the reaction is completed, cool to 35°C Adjust the pH to 7 with sodium hydroxide solution to obtain the target product. When adding dropwise, the stirring speed is 5000r / min, and during heat preservation, the...

Embodiment 22

[0037] The preparation method of novel polycarboxylate water reducer, the steps are as follows:

[0038] Step 1: Prepare or purchase the macromer, and weigh the raw materials according to the predetermined ratio;

[0039] Step 2: Add alkyl polyether, acrylic acid monomer, polymerization inhibitor, catalyst and water coordinating agent into the reaction kettle and raise the temperature to 80°C, carry out esterification reaction for 3 hours in the reflux state, and obtain the intermediate product; the stirring speed is 1800r / min;

[0040] Step 3: Separate the intermediate product and heat it to 60°C to dissolve it, and add other monomers and initiator solutions dropwise at the same time. The dropping time is 1.2 hours. After the dropwise addition, keep warm for 6 hours. After the reaction is completed, cool to 45°C. Adjust the pH to 7 with sodium hydroxide solution to obtain the target product. When adding dropwise, the stirring speed is 4500r / min, and during heat preservatio...

Embodiment 23

[0042] The preparation method of novel polycarboxylate water reducer, the steps are as follows:

[0043] Step 1: Prepare or purchase the macromer, and weigh the raw materials according to the predetermined ratio;

[0044] Step 2: Add alkyl polyether, acrylic acid monomer, polymerization inhibitor, catalyst and water coordinating agent into the reaction kettle and raise the temperature to 150°C, carry out esterification reaction in reflux state for 7 hours, and obtain the intermediate product; the stirring speed is 2000r / min;

[0045] Step 3: Separate the intermediate product and heat it to 40°C for dissolution, and add other monomers and initiator solution dropwise at the same time, the dropping time is 0.6 hours. Adjust the pH to 7.5 with sodium hydroxide solution to obtain the target product. In the step 3, when adding dropwise, the stirring speed is 5200r / min, and during the heat preservation, the stirring speed is 2400r / min;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com