Wave Separator for Enhancing Gas-Liquid Contact and Its Application

A technology of gas-liquid contact and wave evacuator, which is applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of short reaction time, uniform bubble volume, and increased flue gas resistance, so as to save costs and Effects of resource consumption, improvement of purification efficiency, and prolongation of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

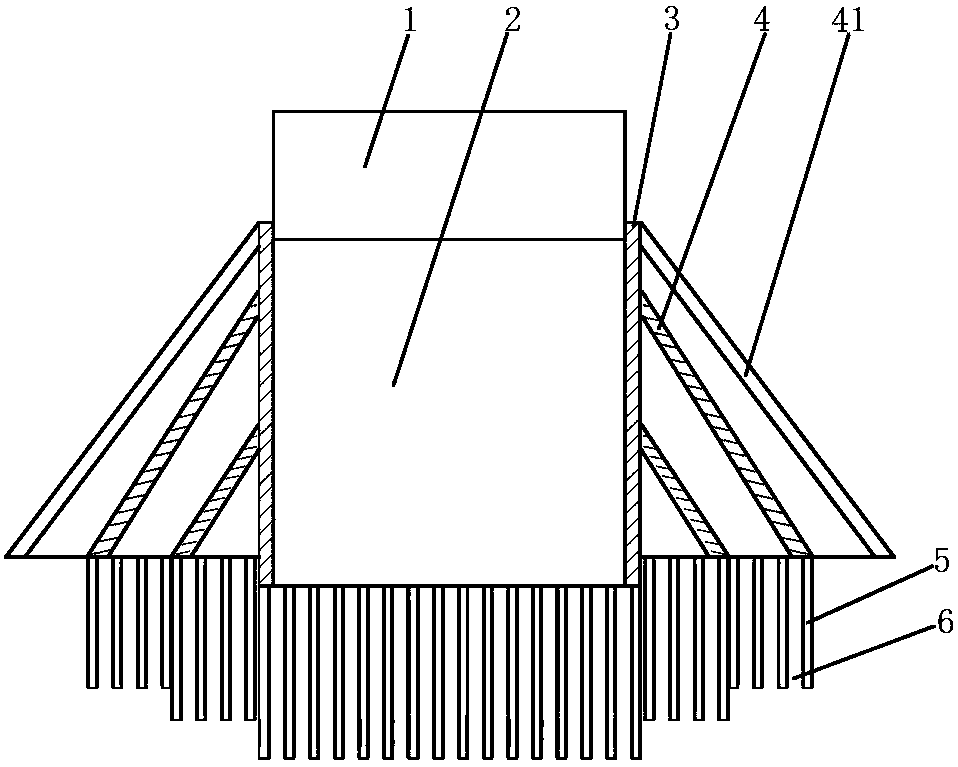

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail as follows:

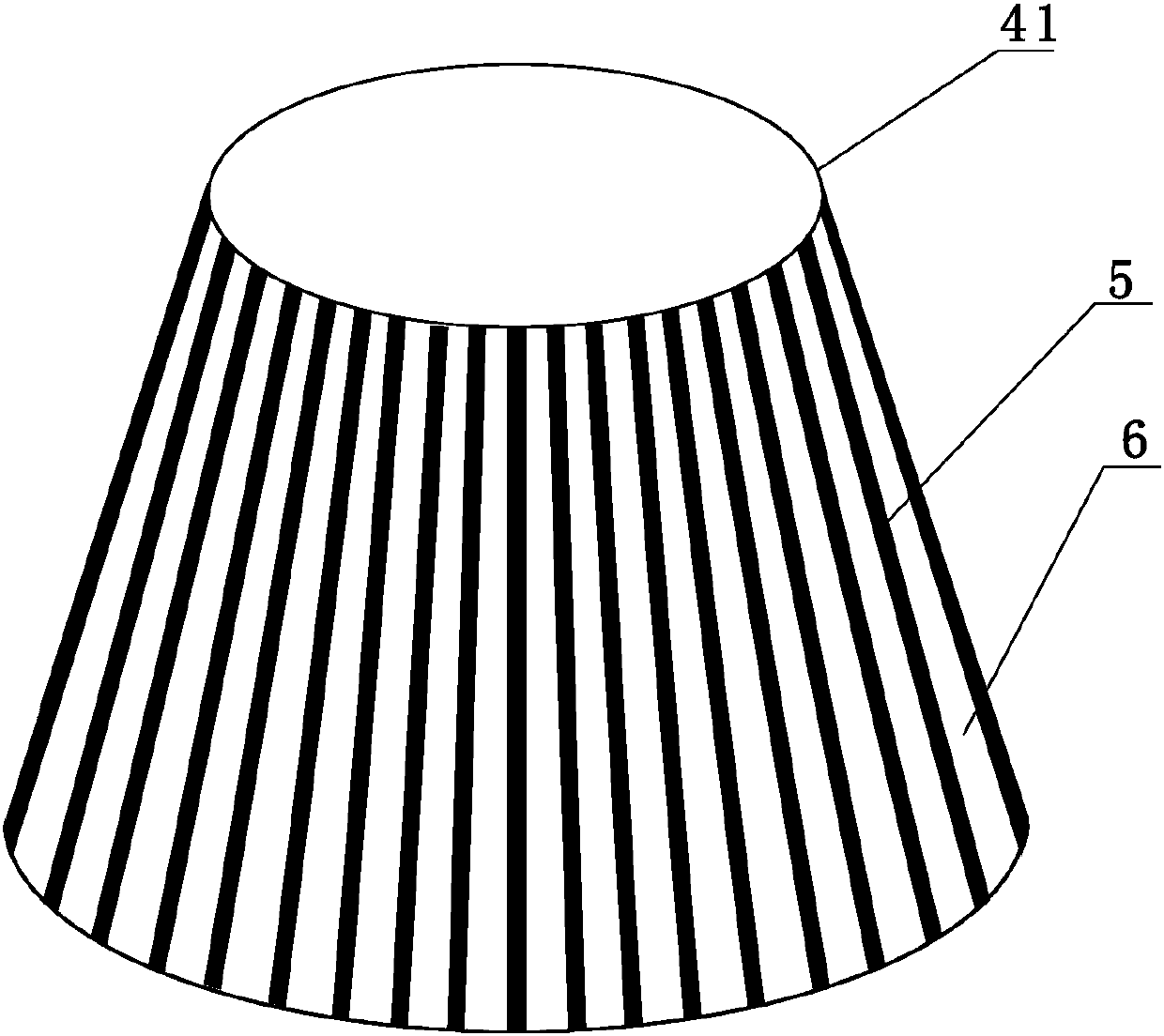

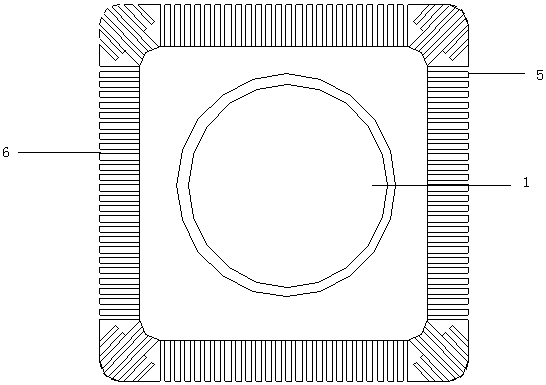

[0031] as attached Figure 1-3 As shown, the present invention includes a smoke pipe 1, and the lower port of the smoke pipe 1 immersed in the treatment liquid is provided with a wave evacuator 2, and the wave evacuator 2 is composed of a hollow tube 3, a barrier plate 4 and a wave evacuation tooth 5, and the barrier The plate 4 is arranged on the outer wall of the hollow tube 3, the corrugation teeth 5 are arranged below the hollow tube 3, the corrugation teeth 5 are arranged on the barrier plate 4, the air groove 6 is formed between the adjacent corrugation teeth 5, and the corrugation teeth 5 are arranged on the barrier plate 4. The gas groove 6 below the hollow tube 3 of the wave device 2 is not higher than the position of the lower port of the smoke tube 1 immersed in the treatment liquid.

[0032] The wave evacuator 2 is set or welded at the lower po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com