Movable jaw mounting assembly

一种安装组件、活动颚的技术,应用在谷物处理等方向,能够解决增加维护更换磨损件等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

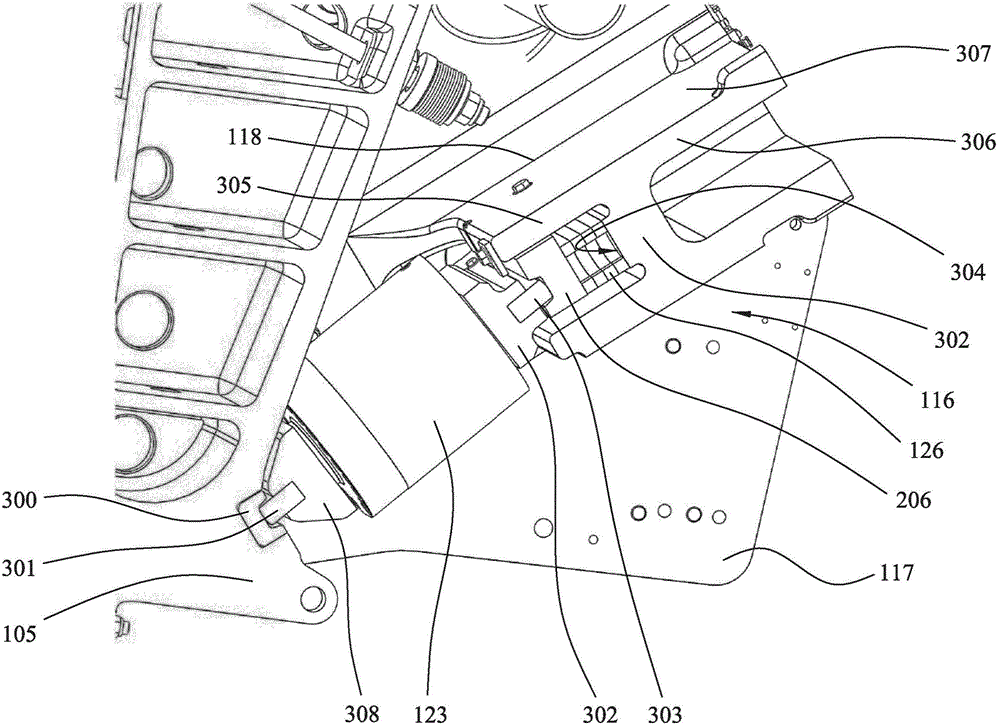

[0033] refer to figure 1, the jaw crusher 100 includes a main frame 102 on which a movable jaw 105 and a substantially fixed jaw 104 are mounted. The movable jaw 105 is mounted eccentrically at a rotatable shaft 107 (extending from below the end cap 109 ) and is positioned apart from and opposite the fixed jaw 104 . The orientations of the fixed jaw 104 and the movable jaw 105 relative to each other converge along their respective lengths such that the spacing between the crushing surface 111 of the fixed jaw 104 and the corresponding crushing surface 110 of the movable jaw 105 decreases in the downward longitudinal direction . A suitable wear plate 113 is removably attached to the crushing face 111 of the fixed jaw 104 and a corresponding wear plate 114 is removably attached to the crushing face 110 of the movable jaw 105 . The main frame 102 includes two opposing frame walls that support a front frame end 108 that is aligned substantially perpendicular to the frame wall 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com