A CNC sieve plate welding machine tool

A technology for welding machine tools and numerical control panels, which is applied to welding power sources, welding equipment, welding equipment, etc., can solve the problems of increased cost and high price of imported sieve plates, and achieve the effects of cost saving, convenient setting and adjustment, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

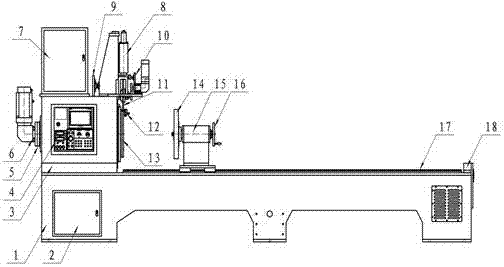

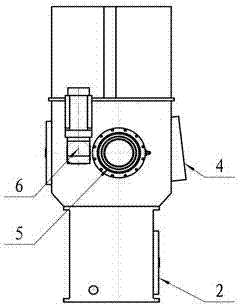

[0019] see Figure 1-2 , a numerical control sieve plate welding machine tool, comprising a machine body 1, a bedside box 3, a numerical control panel and an operation display touch screen 4, a spindle drive servo motor and a speed change device 6, a longitudinal moving device 15 and a linear guide rail 17; the machine body 1 A power supply box 2 is installed at the bottom, and the power supply box 2 is used to supply power for the entire machine tool; a bedside box 3 is installed on the upper side of the power supply box 2; The numerical control panel and the operation display touch screen 4 include a touch screen, PLC and corresponding modules to form the control unit of the whole machine. The touch screen is a large color touch screen, which is an interface for man-machine exchange of operation display. The operator can input relevant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com