Method for Locating Oscillating Sources of Plant-Level Control Loops in Process Industry

A control loop, process industry technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problem of low detection accuracy, achieve the effect of improving accuracy and eliminating serious harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

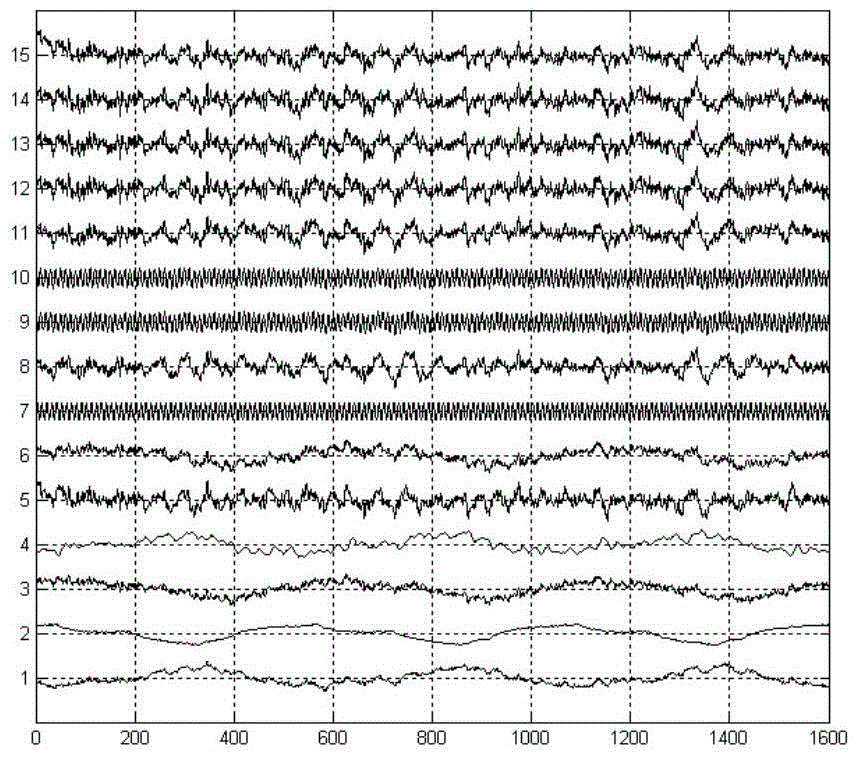

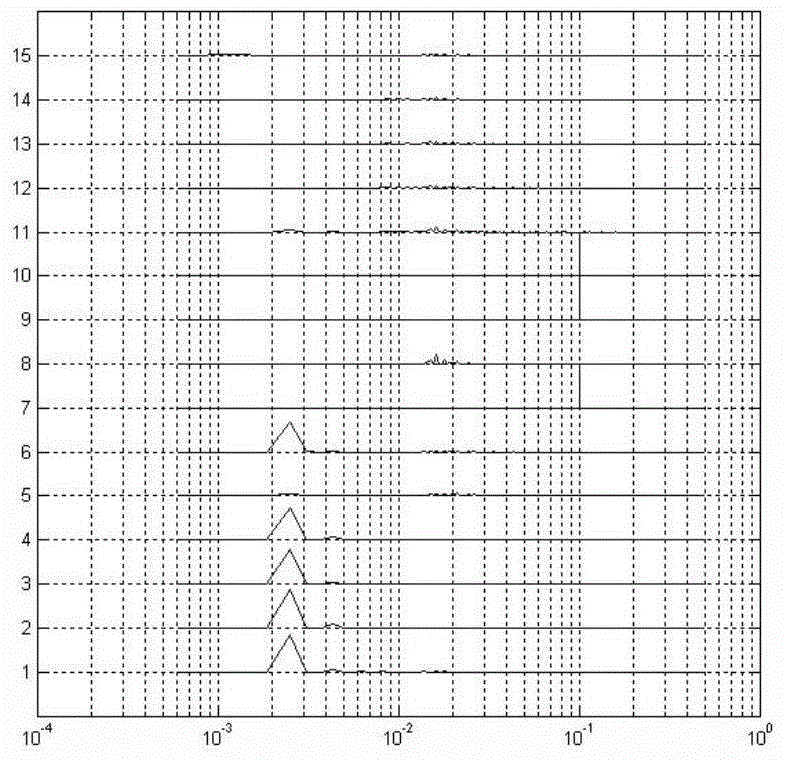

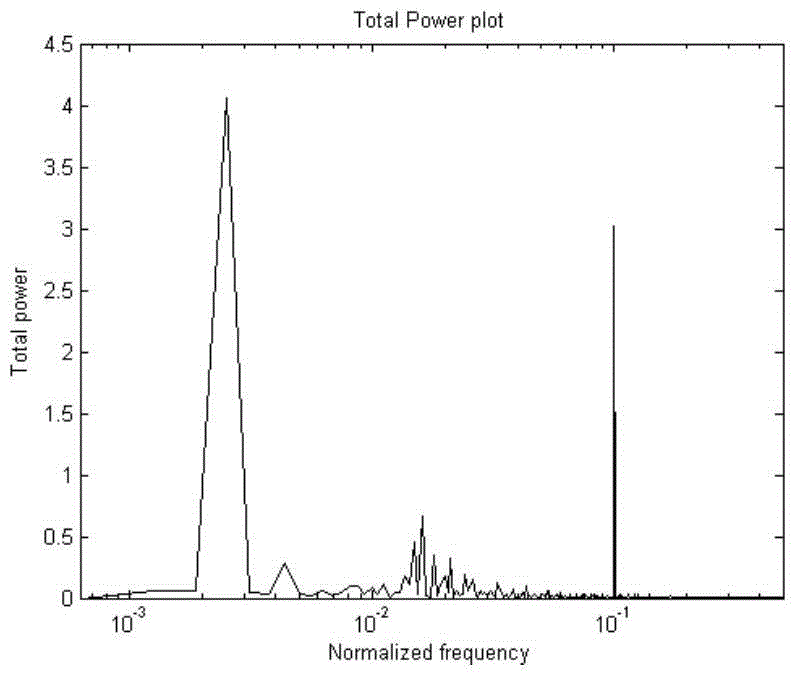

[0015] The present invention is described in conjunction with the accompanying drawings. The basic principle of the present invention for positioning the oscillation source of the process industry plant-level control loop is as follows:

[0016] First, assume that in a multi-loop control system with N loops, multi-loop oscillation occurs. That is to say, there are M loops where loop signal oscillation occurs. Obviously, M≤N. An original loop variable data set A that only includes the above M loop signal oscillations is constructed. There are M elements in the data set A which are composed of sampled data sequences of length S. If using matrix A M×S To represent the data set A, then A M×S The dimension of the matrix is: M×S, namely A M×S =[a 1 ,a 2 ,···,a M ] T , where a i (i=1,2,···,M) represents the sampling data sequence of the i-th loop.

[0017] Secondly, for the data set A, combined with frequency-domain non-negative matrix factorization (NMF) or frequency-doma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com