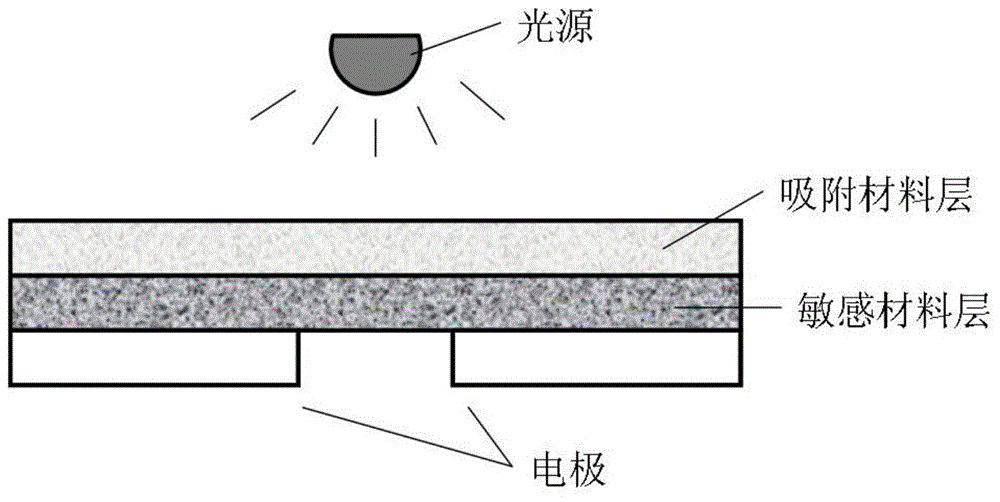

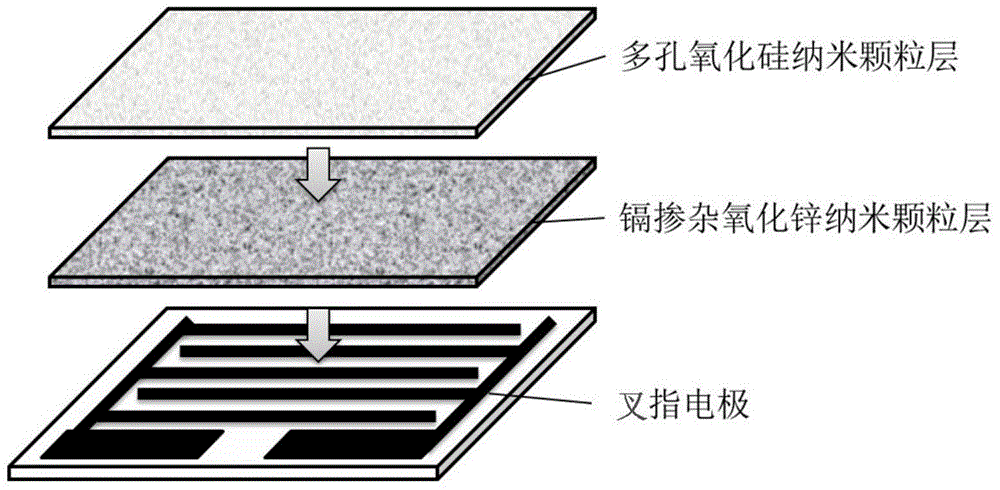

Double layer structural photocatalytic formaldehyde sensor and preparation method thereof

A formaldehyde sensor, double-layer structure technology, applied in the direction of material resistance, can solve problems such as unsuitable application, and achieve the effect of improving sensitivity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

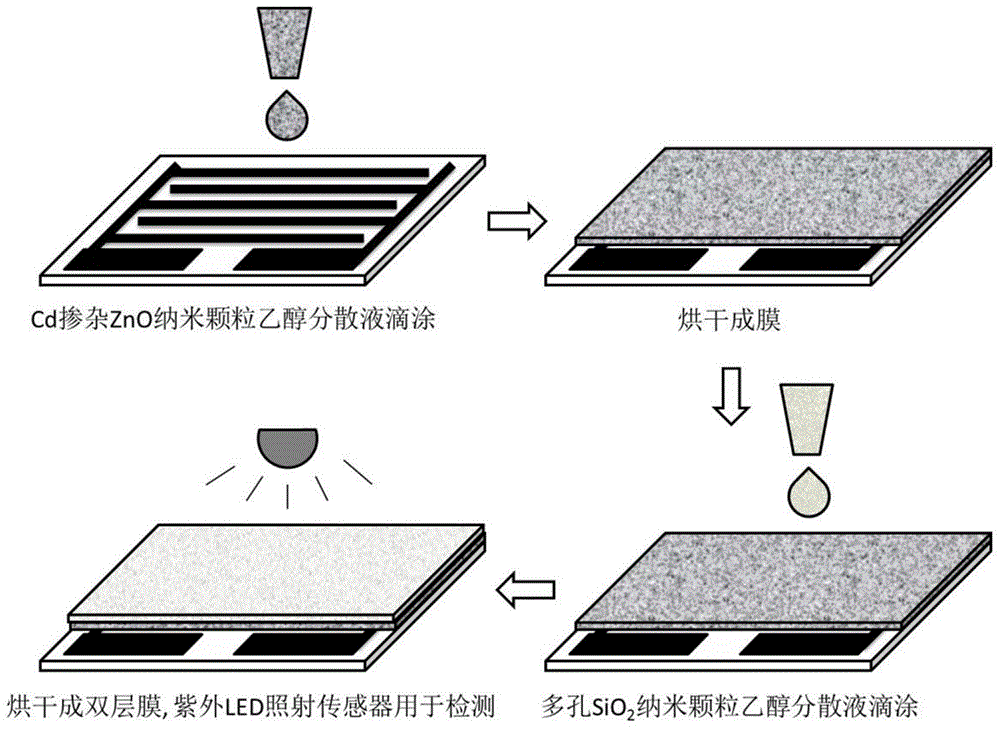

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Synthesis of ZnO nanoparticles

[0035] 10.77g ZnSO 4 ·7H 2 O (375 mmol) was dissolved in 25 mL deionized water. The solution was added dropwise to 50mL100g / L (1.36mmol / L) NH 4 HCO 3The solution was stirred for 1 h in a water bath at 40°C. The supernatant was removed, and the precipitate was washed three times with 15 mL of deionized water each time, and then the precipitate was dried at 80 °C for 12 h and at 120 °C for 2 h. After baking, the samples were calcined in a muffle furnace at 500 °C for 2 h.

[0036] Step 2: Addition of cadmium element

[0037] Weigh 0.4 g of pre-prepared ZnO nanoparticles and disperse them in 60 mL of cadmium salt solution (3CdSO 4 ·8H 2 (00.019g), the solution was stirred at 80°C and the solvent was evaporated to dryness, then the precipitate was dried at 80°C for 12h and at 120°C for 2h. After this the precipitate was calcined at 450°C.

[0038] Step 3: Synthesis of porous silica nanoparticles

[0039] 6.4 mL of water, 0...

Embodiment 2

[0050] The method of step 2 in embodiment 1 can be replaced by following scheme:

[0051] Step 2: Addition of cadmium element

[0052] Weigh 0.4 g of pre-prepared ZnO nanoparticles and disperse them in 60 mL of cadmium salt solution (3CdSO 4 ·8H 2 (00.019g), the solution was stirred at 70°C and the solvent was evaporated to dryness, then the precipitate was dried at 70°C for 10h and at 110°C for 1h. After this the precipitate was calcined at 400°C.

Embodiment 3

[0054] The method of step 2 in embodiment 1 can be replaced by following scheme:

[0055] Step 2: Addition of cadmium element

[0056] Weigh 0.4 g of pre-prepared ZnO nanoparticles and disperse them in 60 mL of cadmium salt solution (3CdSO 4 ·8H 2 (00.019g), the solution was stirred at 90°C and the solvent was evaporated to dryness, then the precipitate was dried at 90°C for 14h and at 130°C for 3h. After this the precipitate was calcined at 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com