A kind of concrete piston and its raw material preparation method

A technology of concrete pistons and raw materials, applied in mechanical equipment, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve the problems of reducing friction coefficient, large friction coefficient, short service life, etc. The effect of small friction coefficient, improved wear resistance, and improved tear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

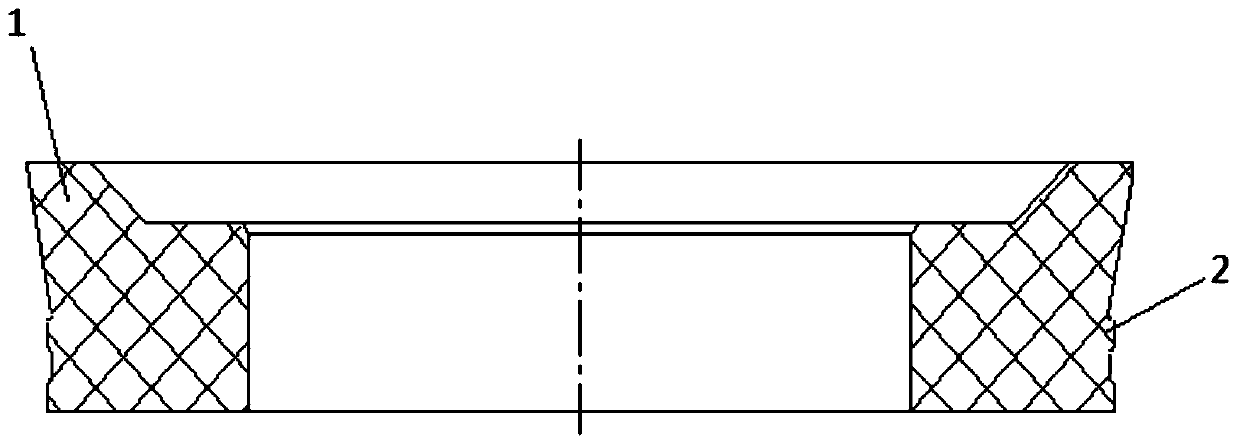

[0019] A concrete piston, comprising a rubber body 1, the rubber body 1 is configured as a ring structure, the rubber body 1 is provided with a fiber layer, the upper outer side of the rubber body 1 is configured as an inverted trapezoid, and the upper inner side of the rubber body 1 is provided with an inverted trapezoidal hollow Part, the lower outer side of the rubber body 1 is provided with two rectangular raised structures 2, the rubber body 1 between the two rectangular raised structures 2 is set as a cylindrical ring, and the lower inner side of the rubber body 1 is provided with a cylindrical hollow part, an inverted trapezoidal hollow transition part is provided between the inverted trapezoidal hollow part and the cylindrical hollow part inside the rubber body 1 .

[0020] In the above examples, the rubber material used in it includes the following components in parts by weight: 100 parts of NBR, 5-8 parts of ZnO, 1 part of SA, 1-3 parts of anti-aging agent, 30-40 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com