Bottom beam for roadway hydraulic support high in energy absorption speed, burnt resistant and floor heave resistant

A hydraulic support and anti-collision technology, which is used in pillars/supports, mining equipment, earth-moving drilling, etc., can solve the problems of lack of buffer and pressure, instability and damage, and breakage, so as to ensure long-term repeated use and alleviate impact. , The effect of preventing instability and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

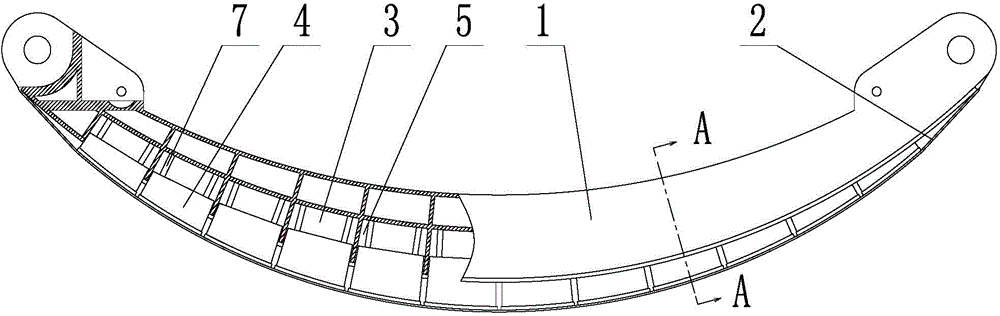

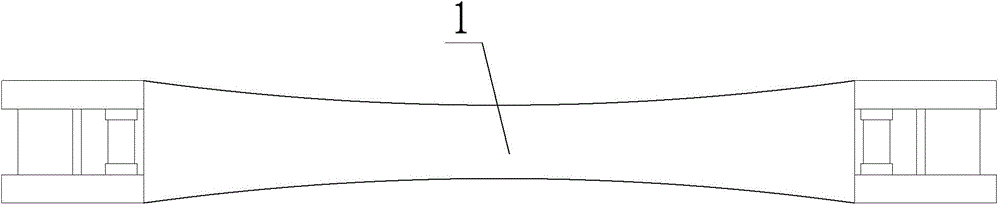

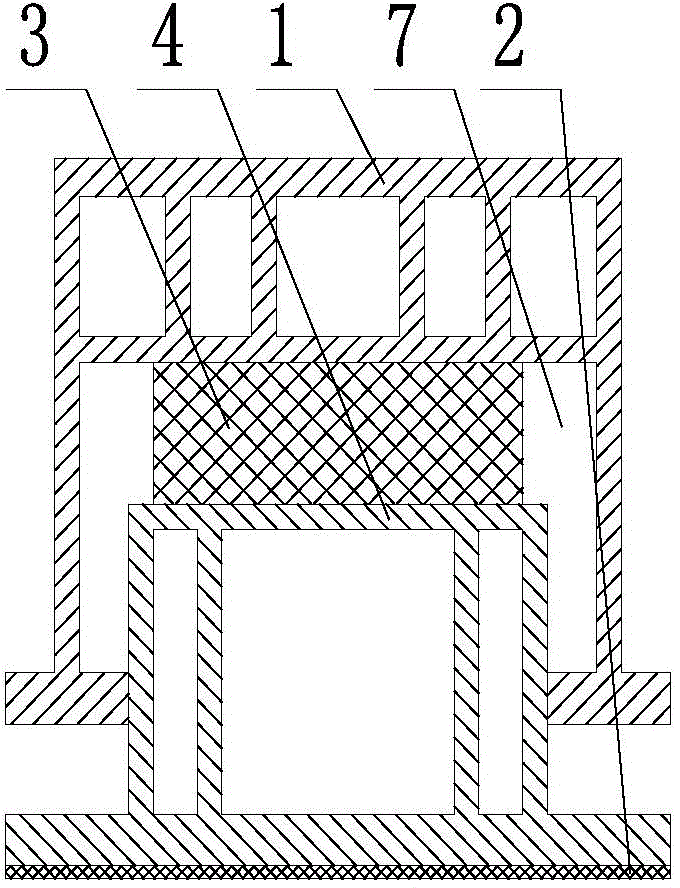

[0021] Such as figure 1 , 2 , shown in 3 and 4, a roadway hydraulic support bottom beam with rapid energy absorption, impact resistance and bottom sag, including a reverse arched variable cross-section box beam 1, stamping energy-absorbing components and carbon fiber cloth 2, in the reverse arch variable cross-section There are several stamping energy-absorbing assembly installation cavities 7 evenly distributed in the box beam 1, the stamping energy-absorbing assembly is located in the stamping energy-absorbing assembly installation cavity 7, the carbon fiber cloth 2 is located on the lower side of the stamping energy-absorbing assembly, and is connected with the stamping energy-absorbing assembly The lower part of the component can be closely fitted, and the end of the carbon fiber cloth 2 is firmly connected with the inverted arch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com