Anti-coking alkylbenzene synthesis heat conduction oil and preparation method thereof

A technology for anti-coking alkyl benzene and coking alkyl benzene, which is applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor comprehensive stability of the system, coking and blockage of pipelines, etc., and achieve outstanding low temperature tolerance performance and reduce Emissions, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

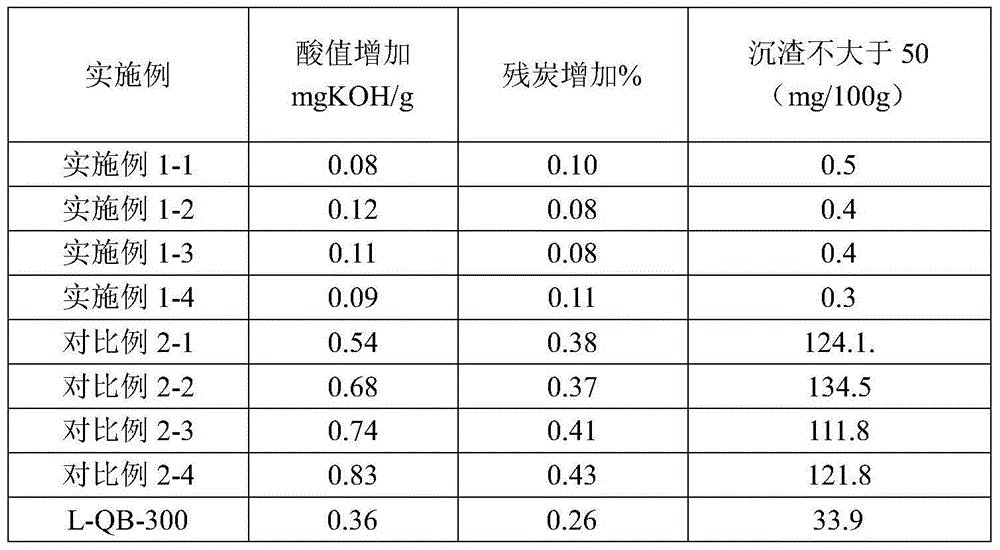

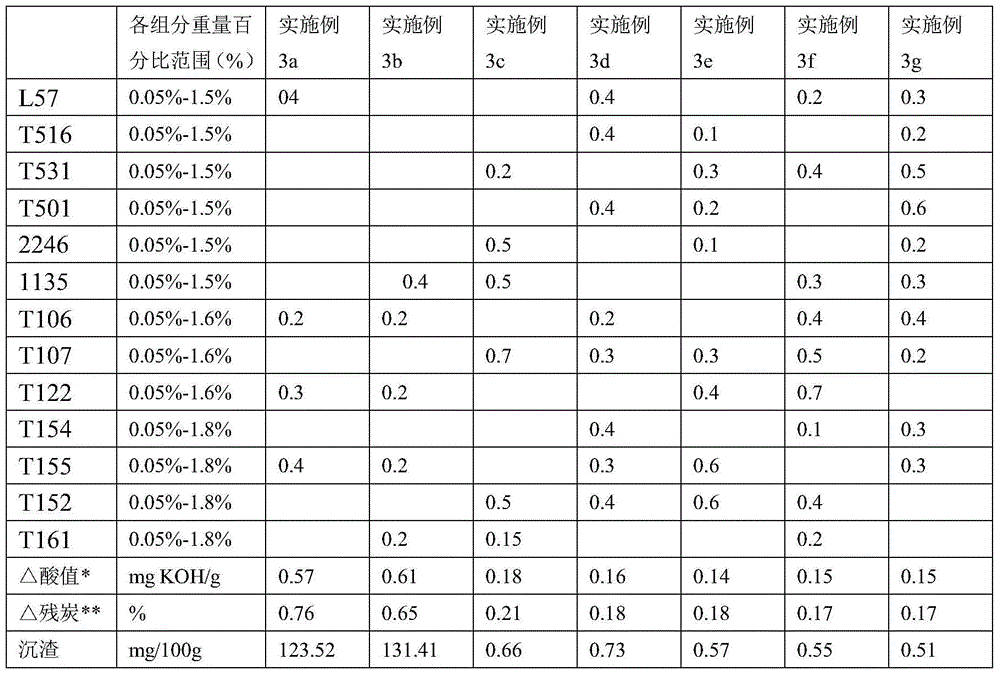

Examples

Embodiment 1-1

[0042] The total amount of anti-coking alkylbenzene heat transfer oil is 1000Kg, which is made of alkylbenzene base oil 974Kg, T5344Kg, 22464Kg, T1065Kg, T1224Kg, T1559Kg. The alkylbenzene base oil: initial boiling point>320°C, density>0.83g / cm3, flash point>190°C, carbon residue<0.05%, acid value<0.03mg KOH / g, pour point<-55°C, Copper sheet corrosion is less than grade 1 (tested according to GB / T 5096, 100°C, 3h).

Embodiment 1-2

[0046] The total amount of anti-coking alkylbenzene heat transfer oil is 1000Kg, which is made of alkylbenzene base oil 980Kg, L574Kg, T5014Kg, T1225Kg, T1547Kg. The alkylbenzene base oil: initial boiling point>320°C, density>0.83g / cm3, flash point>190°C, carbon residue<0.05%, acid value<0.03mg KOH / g, pour point<-55°C, Copper sheet corrosion is less than grade 1 (tested according to GB / T 5096, 100°C, 3h).

Embodiment 1-3

[0050] Take 972Kg of alkylbenzene base oil, heat it to 120°C, and keep it for 1 hour to remove water and light components in the base oil. Analysis shows that the water content in the base oil is 280mg / Kg. Add solid additives: T5163Kg and T5013Kg, stir and dissolve completely. Continue to cool down to 80° C., L574Kg, T1078Kg, T154 and T155 each 5Kg, stir, and mix evenly to obtain the finished anti-coking alkylbenzene heat transfer oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com