Preparation method of collagen-degradation-product-based sand-fixing water-retention agent

A collagen and degradable technology, applied in chemical instruments and methods, fertilizer mixtures, applications, etc., can solve the problems that waste cannot be buried and incinerated, hinder the sustainable development of tanning, and achieve good environmental and economic benefits. Improve wind erosion resistance, compressive strength, and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

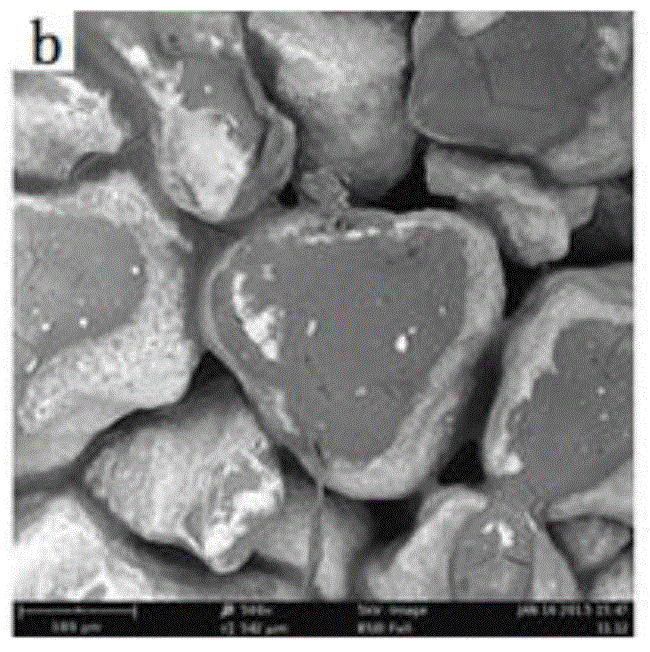

Image

Examples

Embodiment 1

[0022] The preparation method of the sand-fixing and water-retaining agent of protein degradation products comprises the following processes:

[0023] (1) Extraction of collagen degradation products

[0024] After washing and drying the shavings and leftover scraps of cowhide, sheepskin, and pigskin wet blue leather, they are crushed to particles with a particle size of less than 1 cm, and subjected to high-temperature treatment with 12% slaked lime solution for 5 hours at a temperature of 85 At a temperature of ~90°C, adjust the pH to neutral with sulfuric acid, and then undergo decolorization, flocculation, and liquid-solid pressure filtration separation to obtain a collagen degradation solution. The relative mass fraction of collagen degradation products in the collagen degradation solution is 50%, containing Cr 2 o 3 ≤5mg / kg, containing ash ≤5g / kg, the appearance is a light yellow transparent solution, and the relative molecular weight of the collagen degradation product...

Embodiment 2

[0029] The preparation method of the sand-fixing and water-retaining agent of protein degradation products comprises the following processes:

[0030] (1) Extraction of collagen degradation products

[0031] After washing and drying the shavings and leftover waste of cowhide, sheepskin, and pigskin wet-blue leather, crush them to particles with a particle size of less than 1 cm, and perform a high-temperature treatment with a slaked lime solution with a mass content of 5% for 10 hours at a temperature of 85 At a temperature of ~90°C, adjust the pH to neutral with sulfuric acid, and then undergo decolorization, flocculation, and liquid-solid pressure filtration separation to obtain a collagen degradation solution. The relative mass fraction of collagen degradation products in the collagen degradation solution is 50%, containing Cr 2 o 3 ≤5mg / kg, containing ash ≤5g / kg, the appearance is a light yellow transparent solution, and the relative molecular weight of the collagen degr...

Embodiment 3

[0036] The preparation method of the sand-fixing and water-retaining agent of protein degradation products comprises the following processes:

[0037] (1) Extraction of collagen degradation products

[0038] After washing and drying the shaved leather scraps and leftover scraps of cowhide, sheepskin, and pigskin wet-blue leather, crush them to particles with a particle size of less than 1 cm, and perform high-temperature treatment with 8% slaked lime solution for 7 hours at a temperature of 85 At a temperature of ~90°C, adjust the pH to neutral with sulfuric acid, and then undergo decolorization, flocculation, and liquid-solid pressure filtration separation to obtain a collagen degradation solution. The relative mass fraction of collagen degradation products in the collagen degradation solution is 50%, containing Cr 2 o 3 ≤5mg / kg, containing ash ≤5g / kg, the appearance is a light yellow transparent solution, and the relative molecular weight of the collagen degradation produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com