Intermittent reaction-continuous reaction rectification combined process for catalytic synthesis of oxalic acid

A technology of reactive distillation and combined process, which is applied in the chemical industry, sustainable manufacturing/processing, separation/purification of carboxylic acid compounds, etc., and can solve the problems of complicated purification and separation of follow-up products, long reaction time, high water-ester ratio, etc. , to save energy and investment, reduce energy consumption, and reduce water-ester ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

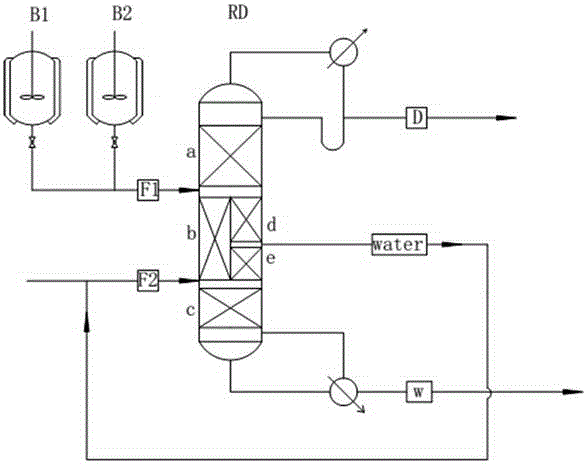

[0029] Water and dimethyl oxalate are mixed in a molar ratio of 5:1, and enter the batch reactor for preliminary reaction at 65°C. After 3 hours of reaction, the feed is fed to the next-door rectification tower, and the reaction liquid in the batch reactor is fed from the upper feed port. Continuously enter the reaction zone (zone b) of the dividing wall tower RD, and the normal temperature water with a corresponding ratio (total water-to-ester ratio of the whole process is 10:1) enters the tower from the lower feed port of the reaction zone (zone b), and the top of the tower conveys the reaction process The methanol generated in the reactor is continuously discharged, part of the water is continuously produced from the lower part of the rectification zone (zone d) on the right side of the dividing wall, and oxalic acid, excess water and a very small amount of methanol are continuously produced from the tower kettle. The specific parameters are as follows:

[0030] (1) The volu...

Embodiment 2

[0037] Water and dimethyl oxalate are mixed in a molar ratio of 4:1, and enter the batch reactor for preliminary reaction at 60°C. After about 4 hours, the feed is fed to the next-door rectification tower, and the reaction liquid in the batch reactor is fed from the upper feed port. Continuously enter the reaction zone (zone b) of the dividing wall tower RD, and the normal temperature water with the corresponding ratio (total water-to-ester ratio of the whole process is 10:1) enters the tower from the lower feed port of the reaction zone (zone b), and the top of the tower conveys the reaction process The methanol generated in the reactor is continuously discharged, part of the water is continuously produced from the lower part of the rectification zone (zone d) on the right side of the dividing wall, and oxalic acid, excess water and a very small amount of methanol are continuously produced from the tower kettle. The specific parameters are as follows:

[0038] (1) The volum...

Embodiment 3

[0045]Water and dimethyl oxalate are mixed in a molar ratio of 5:1, and enter the batch reactor for preliminary reaction at 65°C. After 3 hours of reaction, the feed is fed to the next-door rectification tower, and the reaction liquid in the batch reactor is fed from the upper feed port. Continuously enter the reaction zone (zone b) of the dividing wall tower RD, and the normal temperature water with the corresponding ratio (total water-to-ester ratio of the whole process is 11:1) enters the tower from the lower feed port of the reaction zone (zone b), and the top of the tower conveys the reaction process The methanol generated in the reactor is continuously discharged, part of the water is continuously produced from the lower part of the rectification zone (zone d) on the right side of the dividing wall, and oxalic acid, excess water and a very small amount of methanol are continuously produced from the tower kettle. The specific parameters are as follows:

[0046] (1) The vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com