Automatic loading-unloading type storage rack warehousing device

An automatic loading and unloading and shelf technology, applied in storage devices, transportation and packaging, etc., can solve problems such as personal accidents, increased labor costs, shelf deformation, etc., and achieve the effects of high automation, increased storage rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the automatic loading and unloading shelf storage device of the present invention in conjunction with the accompanying drawings.

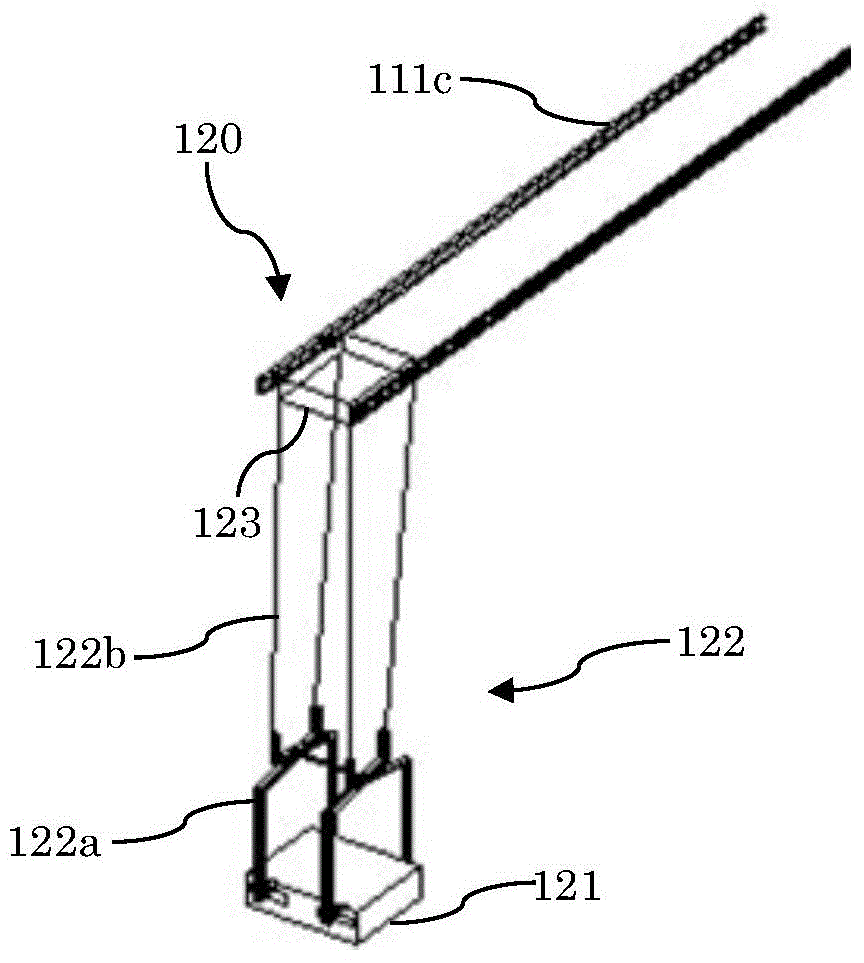

[0020] figure 1 It is a front view of the automatic loading and unloading shelf storage device in the embodiment of the present invention.

[0021] Such as figure 1 As shown, the automatic loading and unloading shelf storage device 100 is used for storing goods, does not need to use a forklift to load and unload goods and can increase the storage rate. The automatic loading and unloading shelf storage device 100 includes: a storage unit 110 , an access unit 120 and a control unit 130 .

[0022] The holding part 110 is used to hold the goods, and the holding part 110 includes: six storage units 111, and each storage unit 111 includes: a support 111a, and 5 pairs stacke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com