Bladder-type storage tank for high concentration hydrogen peroxide

A technology of hydrogen peroxide and capsule storage tanks, which is applied in the direction of containers, packaging, transportation and packaging, etc. It can solve the problems of explosion and damage to pipelines, and achieve the effects of wide selection, uniform force and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

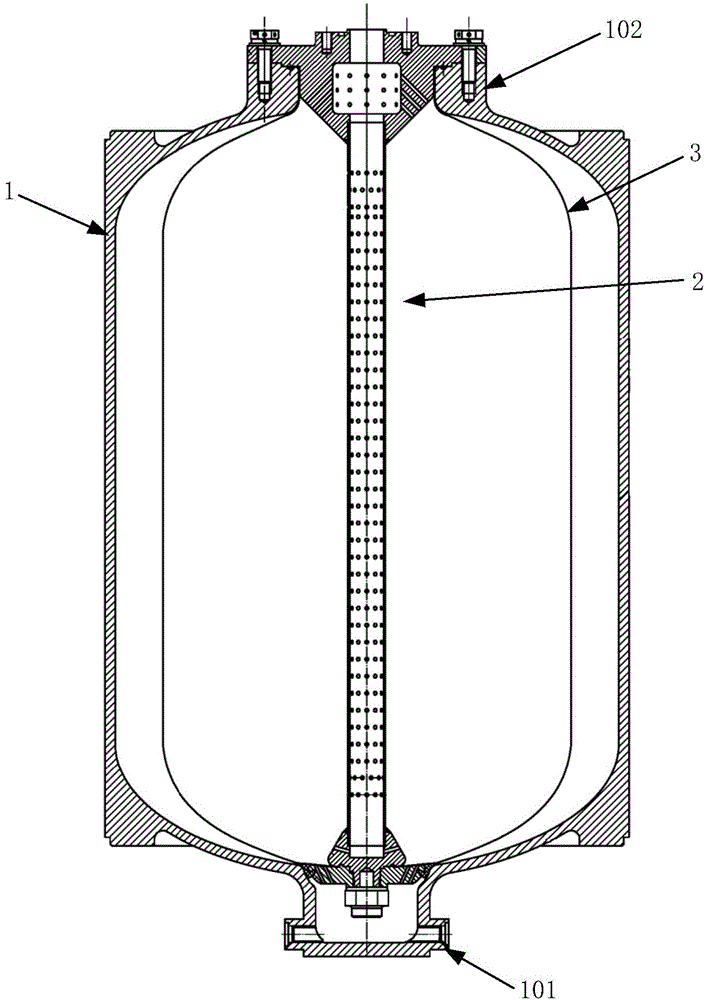

[0030] The present invention proposes a capsule type storage tank suitable for high-concentration hydrogen peroxide, comprising a storage tank casing 1, a filling and leakage assembly 2 and a membrane liquid capsule 3, such as figure 1 shown.

[0031] The tank shell 1 is a cylindrical shell, and the upper and lower ends are constricted openings. The tank shell 1 is made of LD10 as a whole, and the surface is anodized, compatible with hydrogen peroxide grade 2. The lower end of the storage tank shell 1 is used as a pressurized gas inlet, and a pressurized pipeline interface 101 is designed to connect the pressurized pipeline so that the pressurized gas passes into the storage tank shell 1 through the pressurized pipeline interface. The upper end of the tank shell 1 serves as the liquid propellant outlet, and is designed with a mounting flange 102 for installing the filling and leaking assembly 2 .

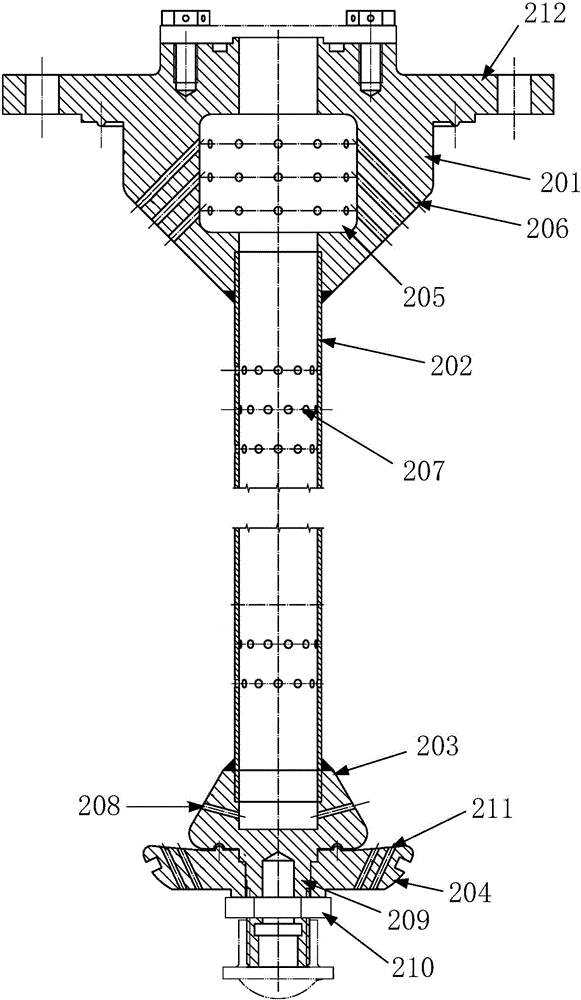

[0032] The filling and leaking assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com